Sometimes top-loading chest freezers outperform those with shelves and drawers. This usually happens if you need to store many identical or almost identical products.

Candy CCM200R will be appreciated by owners of small retail outlets and those who like to make a lot of frozen preparations. We have proven this with practical tests — see for yourself.

Characteristics

| Manufacturer | Candy |

|---|---|

| Model | CCM200R |

| Type | chest freezer |

| Country of Origin | Russia |

| Guarantee | 1 year |

| Life time * | 7 years |

| Power | 85 W |

| Volume | 199 l |

| Performance | 9 kg/day |

| Energy efficiency class | A |

| Electricity consumption per year | 290 kWh |

| Climate class | SN/N/ST/T |

| Noise level | 38 dBA |

| Control | manual, mechanical |

| Coolant | R600a, 60 g |

| Weight | 33 kg |

| Dimensions (W×H×D) | 845×820×555 |

| Length of network cable | 1.6 m |

* Contrary to popular belief, this is not a period after which the device will necessarily break down. However, after this period, the manufacturer ceases to bear any responsibility for its functionality and has the right to refuse to repair it, even for a fee.

Equipment

The Candy CCM200R chest freezer is supplied in a cardboard box, which is installed on a foam base and secured to it with nylon slings.

There is a small amount of information on the packaging: in addition to transportation instructions, it contains the manufacturer’s logo and the words “freezer” in eleven languages. To check whether the model you ordered is correct, you need to pay attention to the paper sticker on one of the sides of the box, which also contains the serial number of the device.

Upon unpacking, we found the freezer itself with a basket already installed, a plastic ice scraper, a user manual, and the obligatory energy efficiency sticker.

At first sight

The Candy CCM200R body is a parallelepiped made of metal coated with white enamel. On top there is a plastic hinged lid.

At the bottom of the front panel there is a control unit (we will look at it a little later, when we install and turn on the device) and a hole for draining condensate, closed with a plastic plug.

The left side wall is smooth. On the right we see a metal cover with ventilation holes, behind which the refrigeration unit is hidden.

The heat exchanger of this model is located inside the housing. Only the plastic hinge pads protrude slightly beyond the dimensions of the device on the rear panel.

There are niche handles at the ends of the chest lid, making it convenient to open the device.

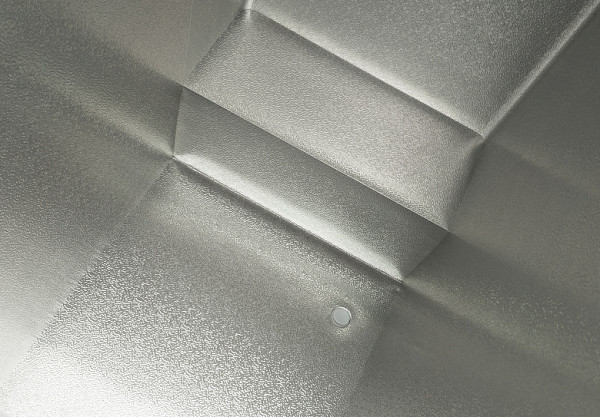

The inside of the freezer is lined with textured aluminum. The walls are smooth, without protrusions or any holders.

The freezer has a warm zone in the form of a removable metal basket, which rests on the side walls. There are no other shelves in the chamber, so food is placed directly on the bottom.

The freezing unit is hidden under the ledge on the right side of the container.

Defrosting the freezer is manual. To drain condensate, there is a drainage hole at the bottom, closed with a rubber stopper.

Instructions

The user manual is an A5 brochure printed on thin, slightly yellowish paper.

The document is compiled in three languages - Russian, Kazakh and Uzbek — and is intended for four similar models of Candy freezers, differing in performance and power.

The Russian-language part of the brochure takes up eight pages. They briefly describe how to prepare the device for operation and explain issues of operation and maintenance.

Control

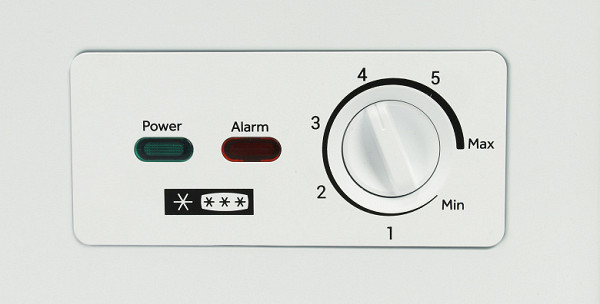

Located in the lower right corner of the front wall, the rectangular control panel consists of two indicators and a round knob that regulates the thermostat.

The selector rotates freely. For convenience, the manufacturer has applied a scale with conditional divisions around it, and in the manual, it has provided approximate temperature values corresponding to the marks.

| Position | Temperature |

|---|---|

| Min | -10…-13 °C |

| 1 | -13…-15 °C |

| 2 | -15…-18 °C |

| 3 | -18…-20 °C |

| 4 | -20…-23 °C |

| 5 | -23…-26 °C |

| Max | -31…-32 °C |

The green indicator on the panel lights up when the device is turned on. The red indicator lights up when the temperature in the chamber becomes higher than normal, which means there are problems with the device.

Exploitation

The chest freezer should be installed in a dry, well-ventilated area, avoiding direct sunlight, heat sources and flammable materials.

You should leave a gap of about 10 centimeters between the device and surrounding objects to ensure proper ventilation and heat dissipation.

Before connecting to the network, it is recommended to leave the unpacked device for at least 2 hours to stabilize the refrigerant.

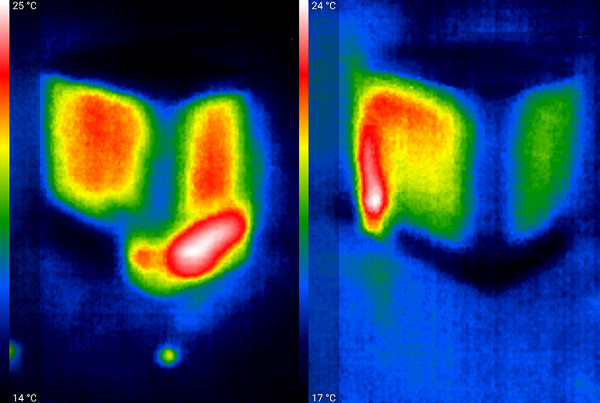

Rear/left and front/right walls of a switched-on freezer in the infrared range

The heat exchanger grids of this model are located behind the walls, which heat up noticeably during operation.

The chest freezer does not have a closed door sensor, so opening the lid will not trigger any alarms or other reactions from the unit.

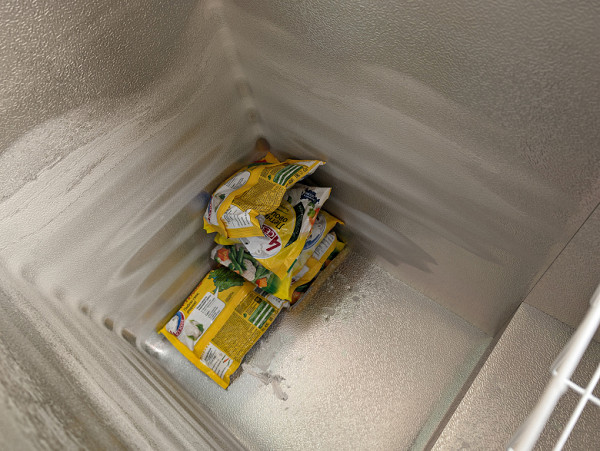

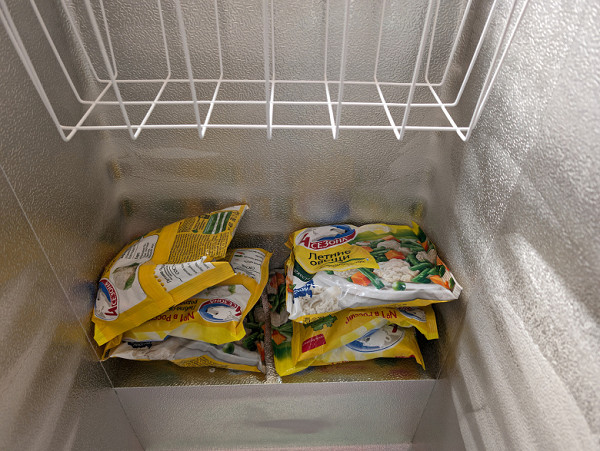

To determine the internal volume of the freezer, we carry out traditional measurements using a tape measure and demonstrate its capacity using examples of standard (400 g) bags of frozen vegetables.

A stack of five 400-gram bags does not reach half the height: with this arrangement, you can put fifteen to seventeen packages inside.

Six bags are placed on the floor of the main volume of the chamber, not in a cramped space. The ledge created by the freezing unit can easily accommodate a couple more stacks.

The Candy CCM200R model does not have an automatic defrost function. The user must independently monitor the condition of the chamber to prevent the formation of an ice coat, and periodically carry out the process of manually defrosting the device.

Care

The manufacturer recommends defrosting the Candy CCM200R device when the layer of ice on its walls reaches a thickness of 5-6 centimeters.

Do not use heating devices for defrosting. Removing ice should be done without using sharp or hard objects that could damage the walls of the freezer.

The accumulated water during defrosting must be drained through the drainage hole located in the lower part of the chamber. Excess moisture is removed with a sponge or rag.

Our measurements

The geometry of the freezer is represented by two parallelepipeds, the sum of their volumes (42×19×50) + (42×52×69) is equal to 190,596 cm³, which is 190.6 liters according to our measurements.

To evaluate the performance and thermal insulation of refrigerators, we use a laboratory complex based on an Arduino mini-computer and DS18B20 digital sensors. These sensors provide an accuracy of ±0.5 °C over a range of −10 to +85 °C and are designed to operate in environments ranging from −55 to +125 °C.

To avoid the influence of heat generation from computer components on the microclimate in the chamber, we install the device outside the refrigerator. The sensors and the mini-computer are connected by three wires with a cross-section of 0.3 mm², which are hermetically protected where the door seal is pressed.

Freezing Power Research

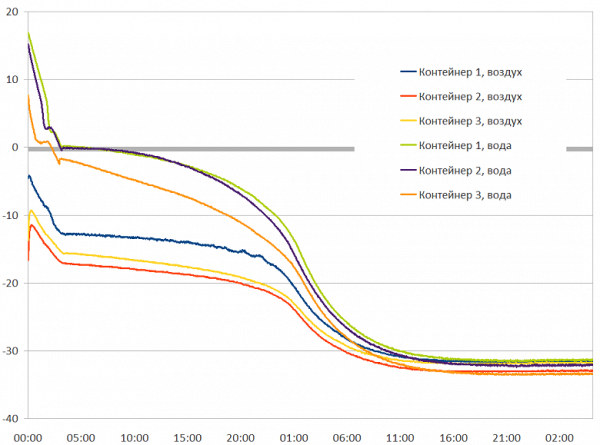

To evaluate the maximum freezing ability of the device, we placed three four-liter containers with room temperature water in it and installed temperature sensors inside each container. Two containers were placed on the floor of the main compartment, the third on a ledge covering the freezing unit. The total volume of water was 12 liters, which exceeds the declared daily freezing capacity (9 kg/day).

Additionally, we placed four temperature sensors at different heights inside the chamber to measure the air temperature.

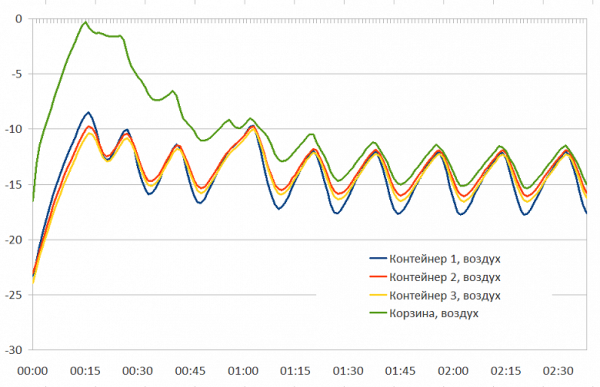

We turned on the chest freezer at full power and waited until the recorded temperature stabilized. The results can be seen in the graph below.

In two containers located on the floor of the main compartment, ice formation began almost simultaneously. According to the sensor data, the temperature in them dropped below zero approximately 5 hours after the start of the test. In the container located above the refrigeration unit, crystallization began much faster: the temperature of the contents dropped to below zero after about 2 hours. After about 38 hours, the air and ice temperatures stabilized at about 32-33 degrees below zero.

Thus, the freezing ability of the device depends on the placement of products in the chamber and corresponds to the declared characteristics. In maximum mode, the compressor of the freezing unit works without interruption, and the graphs show minimal fluctuations in air temperature.

At minimum power, such fluctuations are clearly noticeable: the design of the chest freezer uses a traditional “on/off” compressor.

Defrosting the freezer

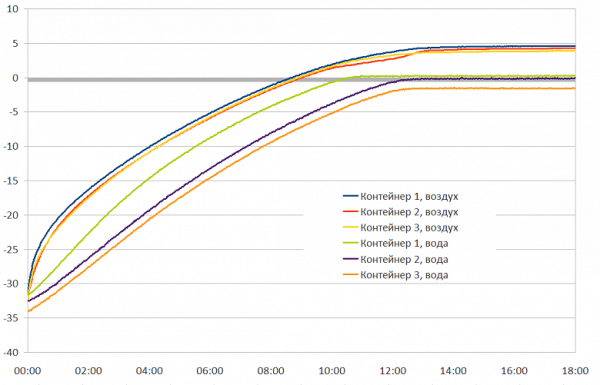

To evaluate the thermal insulation of the case and the time the device remains cold after being unplugged, we turned off the pre-cooled device with water ballast and observed its changes.

Eight hours after the shutdown, the temperature of all three air sensors approached zero.

After about nine hours, a container of water that stood on a ledge inside the chamber began to defrost. The temperature in the water containers remained around freezing for approximately 20 hours from the start of the test.

The volume of frozen ballast did not allow the air temperature to rise above +4...+5 °C within 48 hours after turning off the freezer.

Other measurements

The maximum power consumption of the device is, according to our measurements, approximately 78 W. The noise we measured during operation of the unit does not exceed 36 dBA.

conclusions

A chest freezer is a spacious device designed for long-term storage of large volumes of food. High freezing ability, confirmed by laboratory tests, ensures rapid achievement of low temperatures for a large number of products, preserving their nutritional properties and appearance.

Top loading provides effective cold storage, but removing food from a chest filled to the top may not be very convenient, especially without shelves other than a mesh basket. This limits the use of the chest as a home freezer.

At the same time, such a device will come in handy in retail premises and public catering outlets: it is ideal for long-term storage of large volumes of frozen food.

One of the disadvantages of the device is not the highest thermal insulation.

Pros:

- large volume

- good freezing ability

- low storage temperature

Minuses:

- not very good thermal insulation