The Garlyn NLO 2.0 meat grinder stands out for its slightly increased power (maximum — 2500 W, nominal — 600 W) and original design, which attracts attention with its elegance and lightness. Thanks to an extensive range of accessories, this device can be used as a juicer and vegetable cutter. Great specs on paper, let's see how it performs in practice!

Characteristics

| Manufacturer | Garlyn |

|---|---|

| Model | NLO 2.0 |

| Type | meat grinder, juicer, vegetable cutter |

| Country of Origin | China |

| Guarantee | 1 year |

| Life time * | 3 years |

| Rated power | 600 W |

| Maximum power | 2500 W |

| engine's type | DC (direct current) |

| Number of speeds | 4 |

| Housing material | metal |

| Input tray material | metal |

| Material of knife, discs | stainless steel |

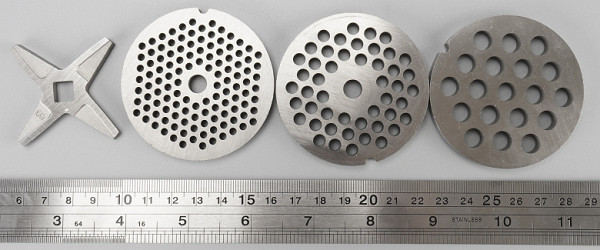

| Number of disks | 3 pcs: 3mm, 5mm, 8mm |

| Maximum cookware height | 12.5 cm |

| Additionally | reverse |

| Protection | from overheating, from overload |

| Accessories | attachment-meat grinder , disks for minced meat, pusher for meat grinder, loading tray, attachment for kebbe, attachment for preparing sausages, burger press, device for cleaning the grate attachment-grater , three attachments for shredding, attachment for potato pancakes, pusher for vegetable cutting attachment- juicer , pusher for the juicer, glasses for juice and pulp |

| Weight | 6.95 kg |

| Dimensions (W×H×D) | 365×165×290 mm |

| Network cable length | 0.94 m |

* Contrary to popular belief, this is not the time limit after which the device will necessarily break down. However, after this period, the manufacturer ceases to bear any responsibility for its performance and has the right to refuse to repair it, even for a fee.

Characteristics

The meat grinder was delivered in two boxes. The top box was made of durable brown cardboard and contained the brand name, model and a schematic representation of the device itself. The second box was decorated in bright orange and black colors and contained photographs of the device itself, all its components, a brief description of the features of the model and its technical characteristics.

There are no carrying handles in the package, but inside you can find an elegant gift ribbon.

The box opens in an unusual way: the top lid folds back, providing access to the top tray with accessories. The body of the meat grinder and attachments for minced meat are located in the lower drawer.

Inside the box were:

- meat grinder body

- neck with a screw inserted into it, a knife and a middle grid

- two additional grilles (with small and large holes)

- pusher for meat grinder

- loading tray

- attachment for making sausages

- kebbe attachment

- burger press

- grate cleaning device

- vegetable cutter attachment

- three graters (slicing, coarse and fine shredding)

- nozzle for potato pancakes

- pusher for vegetable cutter

- juicer attachment

- pusher for juicer

- glasses for juice and pulp

- foam separator partition

- instructions and warranty card

All parts in separate plastic bags were placed in the cells of two foam inserts.

At first sight

Upon first inspection, the meat grinder attracts attention with its elegant shape and “airy” design: the motor unit seems to hang in the air, which gives it a special elegance. The name NLO perhaps alludes to unidentified flying objects, and it makes sense — the «floating» body looks like something out of space.

The stand (bed) of the meat grinder is made of cast metal and painted with silver paint. The metal is light and non-magnetic. The same material is used for the body of the device. The appearance is very impressive, but the matte paint is susceptible to scratches and traces of mechanical stress. Even slight movement on the surface of the table can cause dark streaks and scratches on the body.

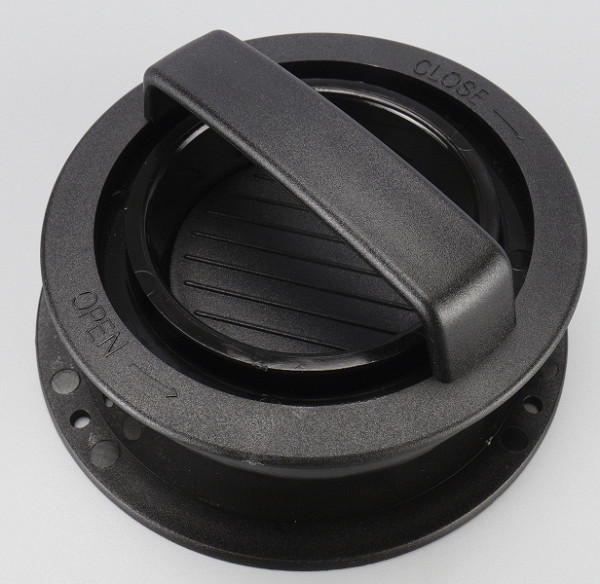

The meat grinder assembly process is simple and intuitive. The loading block is inserted into the corresponding socket of the motor block and secured by turning the plastic lock on the body.

On the back side of the motor block there is a ventilation grill through which hot air exits the housing.

The power cord comes out from the bottom of the motor unit. And if you turn the meat grinder over and look at the underside of the sole, then here we will see a sticker with technical information and four suction cups.

The meat grinder unit consists of: a loading tray with a pusher, a silumin neck, an auger, three steel grates (3, 5 and 8 mm), a knife and a ring nut. All details look neat.

The block is assembled simply and quickly.

The sharpening of the knives is double-sided (it can be installed on either side), and there is room for sharpening them several more times.

An additional accessory is a device for cleaning the grille (but only for the most frequently used ones — medium and large; small ones will have to be cleaned manually).

This mat makes it easy to remove any remaining meat from the holes.

The kit also included a set of attachments for making sausages and kebbe. They, like the pusher, are made of black plastic.

The diameter of the sausage attachments is 2.0, 1.8 and 1.2 cm.

An additional accessory is a burger press, which includes two collapsible plastic containers and a plastic press. It allows you to quickly and easily form patties for burgers and mini burgers.

You can also use them to prepare stuffed cutlets (zrazy)

The loading unit of the juicer includes a loading tray made of translucent plastic with a pusher...

Also included in the kit is a metal mesh filter, a black oblong-shaped auger (hussars, keep quiet!), as well as a lid with a hole for the cake to come out. Juice pours out of a hole at the bottom of the loading block. This is what the entire assembled system looks like:

Translucent plastic containers for juice and waste are the same in shape and differ from each other only in size.

The volume of the container for juice is 0.7 l, for pulp — 0.95 l.

The containers are supplied with a foam separator partition made of the same translucent plastic. Also in the photo we see a plastic loading tray for the juicer.

The vegetable cutting unit has four attachments: a shredder, a coarse and fine grater, and an attachment for potato pancakes.

They are installed in a holder made of black plastic and secured with a latch using a special hinged ring.

This is what the assembled grater block looks like.

The control panel of our meat grinder is touch-sensitive, with LED backlighting. We have access to three buttons plus an on/off button.

Disassembly

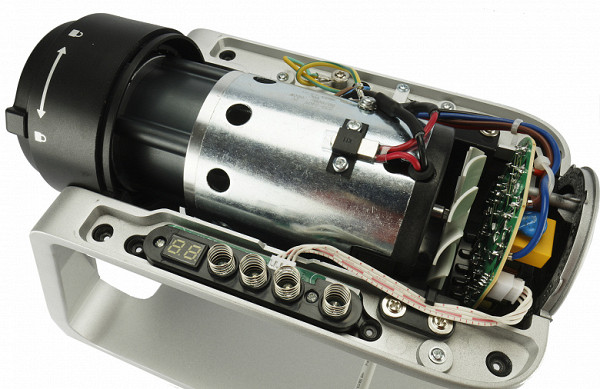

Armed with a screwdriver, we tried to explore the inner world of the meat grinder, but here we failed — we were not able to examine all the elements that interested us.

Inside the cylindrical housing is an electric motor, with the front part housing the gear unit.

There is a fan at the back that keeps the structure cool.

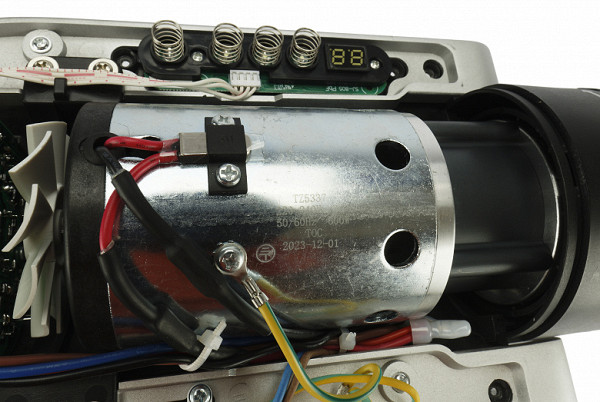

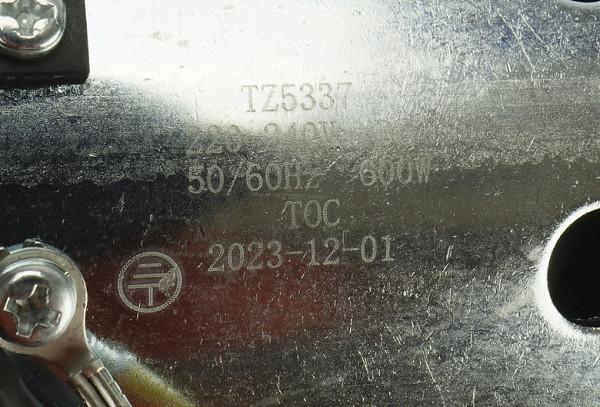

The meat grinder uses a TZ5337 motor with a power of 600 W, according to the markings on the case.

Although due to the design (soft plastic, from which we were afraid to unscrew the screws) we were not able to inspect the gearbox, we can get some information about it. The manufacturer promises the use of a “steel planetary gearbox.”

Considering that a similar motor is used in the very similar Garlyn MG-5000, we have every reason to assume that the gearbox is the same.

Let's look at the photos from the review of the MG-5000 model.

The mechanism consists of six satellite gears: three at the front and three at the rear.

The structure is all metal and filled with copious amounts of thick lubricant. It is especially noticeable that the use of a planetary gearbox is a rather rare occurrence. It's even more interesting to find it here for the second time in a row.

Instructions

The Garlyn NLO 2.0 meat grinder operating manual is presented in the format of a small compact brochure.

This manual includes information about the design of the device, its functionality, safety measures, as well as recommendations for care, storage and troubleshooting. It is written in simple and accessible language, supplemented with illustrations.

In addition, the kit includes a reminder sheet containing a brief summary of the instructions. This sheet can be very handy if you need information quickly without having to look for it in the main brochure.

Control

The electronic control panel is so intuitive that you can use it without reading the instructions. There are only four buttons: on/off, a juicer mode (two speeds — for soft and hard products, respectively), a meat grinder mode (two speeds — for soft and hard meat), and a reverse function.

To start working after connecting to the network, press the power button (on/off), and then select the desired mode and speed with one or two consecutive presses.

After startup, the digital display will display the time elapsed since the device was turned on (in minutes).

The reverse mode is useful if food gets stuck.

Exploitation

The Garlyn NLO 2.0 meat grinder has proven itself to be an effective tool for preparing meat dishes. It successfully handled both tough and soft meats without causing noticeable vibrations in the body and perfectly processed the food. The shredder attachment and grater also pleased with their efficiency, especially when actively working with the pusher.

However, in the juicer area, the results are not so impressive. A meat grinder cannot completely replace a separate juicer, but it can squeeze out a few glasses of juice for your breakfast or evening meal. The manufacturer recommends not to exceed a continuous operating time of 5 minutes, but in our tests the device was always faster. However, the built-in timer will help you keep track of the operating time.

We also note that the manufacturer has provided an elegant solution to prevent overloading of the device by selecting the size of the loading opening in such a way as to avoid excessive amounts of raw materials.

Although the theoretical performance of the device can reach up to 5.5 kg of meat in 2 minutes, in practice this mark is difficult to achieve. However, the main thing is that the process goes smoothly and the result meets expectations.

Care

The body of the meat grinder can be cleaned with a damp cloth, and all removable parts, freed from food residues, should be washed under the tap with a mild detergent. These steps must be performed immediately after use. The use of abrasive and chlorine-containing products, as well as washing parts in a dishwasher, is prohibited.

Our measurements

Depending on the selected type of raw material, the recorded power of the meat grinder ranged from 160 to 320 W. In standby mode, the device consumes 0.3-0.4 W.

Practice tests

Standard testing of meat grinder

The first, traditional test for a meat grinder is minced pork ham.

We cut the meat into pieces of the optimal size and cleaned it of films and excess fat. During grinding, we tried to feed the meat as quickly as possible, as the space inside the meat grinder freed up.

As a result, a kilogram of pork was processed in approximately one minute (1 minute and 4 seconds, according to our stopwatch). After that, we left the grinder running for about 10-15 seconds more to allow any remaining meat to come out.

The quality of the minced meat obtained is assessed as high. We did not find any unprocessed pieces of meat in it. During the process, we only had to use the pusher a few times, mainly when small pieces of meat stuck to the walls of the bell.

After disassembling the meat grinder, we examined the amount of waste and pieces of meat stuck inside. There were very few of them. Mainly, we found remains of veins inside.

Without delaying the matter, we immediately checked the operation of the system for cleaning the grill...

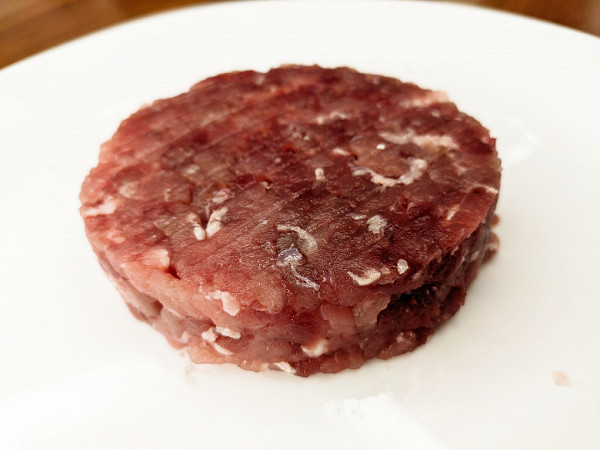

...and some minced meat was placed in a burger press.

After we pressed it with a special press, a nice cutlet formed inside.

Except that the edges weren't perfect. They will have to be crushed by hand.

The performance coefficient for Garlyn NLO 2.0 was 0.937 kg/min.

We rate this test as excellent, considering it more than sufficient for a simple home device.

The degree of use of the device's power during the task did not exceed 165 W.

Result: excellent.

Complex meat (fat + veins)

For the second test, which is aimed at testing the meat grinder's ability to cope with complex tasks, we traditionally use either third-grade stringy meat or meat trimmings.

The starting material for the second test looked exactly the same. To complicate the task, we decided to use a fine grid. However, surprisingly, the grinding process was unchanged from the previous test. The meat was chopped evenly, the meat grinder did not show fatigue and continued to work without problems, and the minced meat came out evenly.

Our meat grinder processed a kilogram of complex raw materials in 1 minute and 25 seconds.

The minced meat was again of ideal quality, with no signs of unground fragments.

What about waste? Having removed the knife and auger, we discovered that there were very few of them.

There were several veins wrapped around the knife, to which a minimal amount of meat was attached.

Result: excellent.

Shredder, grater, potato pancakes

Having started testing attachments for chopping vegetables, we started with the shredder, choosing for this task the task of slicing carrots. The grinding process was quick, but the quality of the shredding was rated as average. The carrot pieces turned out to be of different sizes, often with uneven edges. Such pieces are certainly not suitable for table decoration, but they are quite suitable for use in cooking.

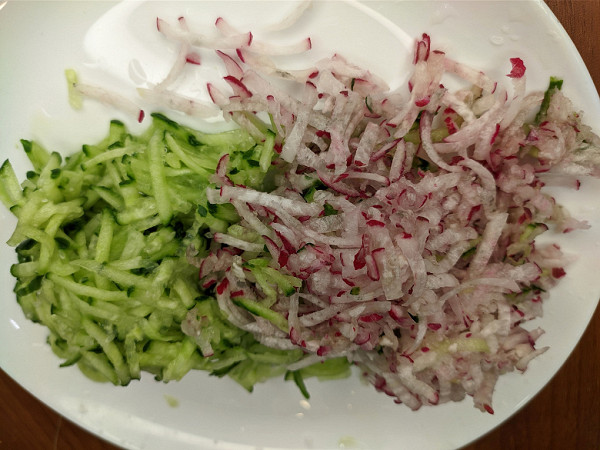

The process of checking the operation of the grater began with the installation of a large grater, which we began to work with cucumbers and radishes. The meat grinder coped with the task easily and quickly, turning our raw materials into a homogeneous and attractive salad base in less than a minute.

Both cucumbers and radishes turned out to be grated equally well.

The waste mainly consisted of cucumber peels.

We continued testing with a fine grater and carrots, and the result pleasantly surprised us. The quality of grinding is rated as ideal, and the speed of work is rated as high.

All that remains is to test the attachment for making potato pancakes. Productivity is important here, because if we decide to prepare potato pancakes, then we need a lot of them. Otherwise there is no point in starting.

The meat grinder coped with 300 grams of potatoes in 1.5 minutes. It's not too fast. It will take about 5 minutes to cook a kilogram of potatoes!

As a result, we got a fine mush.

The amount of waste turned out to be small.

Considering all of the above, we assess the performance of attachments for chopping vegetables as good. Yes, it can be better (especially with food processors). It happens even faster. However, in our case, slicing and shredding are auxiliary, and not the main modes of operation of the device. Because of this, the demand for them is not so great. The main thing is that all the vegetables turned out to be chopped.

Result: good

Juicer attachment

We tested the operation of the auger juicer on grapefruits and carrots.

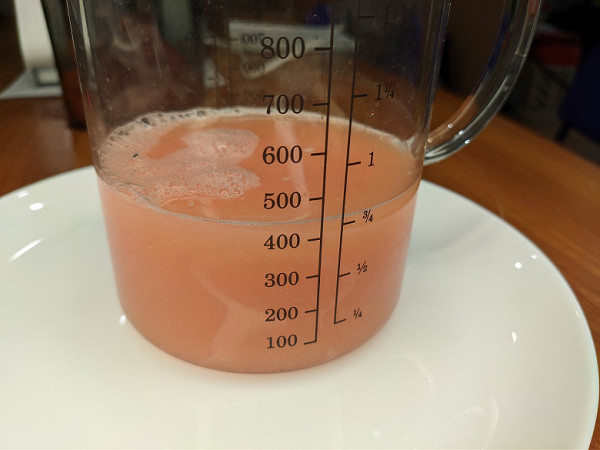

For our first test (grapefruit juice), we took a kilogram of grapefruits.

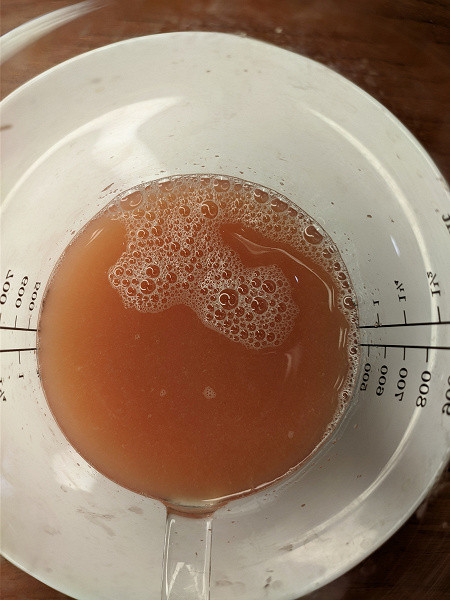

After removing the skin, we had 657 grams of pulp, which we turned into 447 grams of juice in 1 minute and 15 seconds. After finishing the juicer process, we let it sit for about 30 seconds to allow the remaining drips to drain out. The resulting cake turned out to be a little wet.

Juice — without pulp and without seeds.

And also without foam.

The amount of waste remaining inside the device was small.

Let's complicate the task: let's try to feed a kilogram of carrots to the juicer, without particularly helping it, and trying to load the carrots whole, without pre-cutting.

This task turned out to be truly difficult. The juicer worked slowly and with a fairly loud sound, slowly but evenly processing the carrots and dispensing juice. It took almost 5 minutes to process a kilogram of raw materials. When finished we were left with 410g of freshly squeezed juice with a bit of foam.

The waste was again found to be slightly damp.

There were almost no carrot residues inside the meat grinder.

We consider the final result to be satisfactory (and considering that we use an auxiliary attachment, even excellent). Of course, full-size auger juicers will do the job better and more efficiently. However, given the compact dimensions of the auger and the small volume of the spin chamber, it was difficult to expect a better result.

Result: good/excellent

conclusions

The Garlyn NLO 2.0 meat grinder met our expectations. It did an excellent job with soft and tough meat, providing ample opportunities for home use. Our impressions of her work with vegetables were also positive: she cut them evenly into pieces suitable for both salad and Korean carrots. However, the quality of the shredder turned out to be a little lower than expected, with pieces that were not cut very neatly.

The Garlyn NLO 2.0 juicer copes well with small volumes of juice, such as carrots or citrus fruits. However, for processing large volumes of raw materials, it is better to use a separate juicer.

Overall, we were pleased with the performance of the device. It operates quietly, steadily and reliably. However, we're a little concerned about the casing's coating, which doesn't feel durable enough and is prone to scratches. This could be a downside, especially given its unusual design.

It is also worth noting the large number of attachments and accessories that will have to be washed, dried and stored somewhere often. Although we tried using kitchen drawers to store them, it turned out that the best solution was still the original box.

Pros:

- unusual design

- multifunctionality

- small dimensions

- low noise level

- ease of use and maintenance

Minuses:

- mediocre results from the shredding attachment