The Garlyn MG-2000 electric meat grinder is small in size and comes with a wide range of accessories. The set includes three discs for chopping meat to varying degrees, attachments for creating sausages and kebbe, and a vegetable chopping block with five different attachments. For easy storage of perforated grids and additional attachments, a special compartment is provided in the device body.

The manufacturer promises high power and performance. The documentation states that the device is capable of processing up to 5 kg of food in 2 minutes, but does not specify whether these products are meat or vegetables.

Characteristics

| Manufacturer | Garlyn |

|---|---|

| Model | MG-2000 |

| Type | meat grinder |

| Country of Origin | China |

| Guarantee | 1 year |

| Life time * | 3 years |

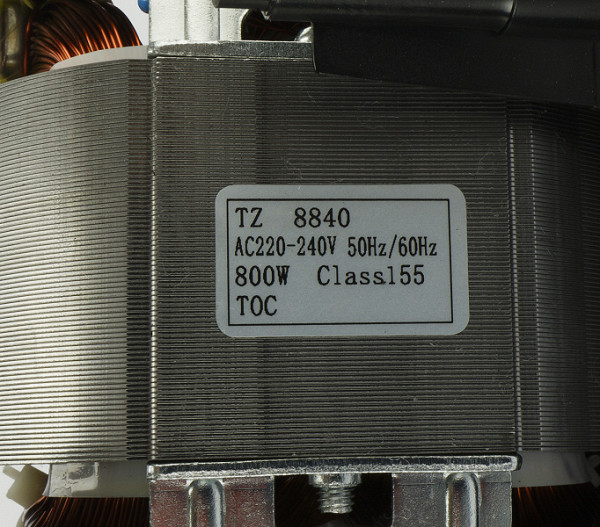

| Rated power | 800 W |

| Maximum power | 2200 W |

| engine's type | AC (alternating current) |

| Number of speeds | 6 |

| Housing material | plastic, metal |

| Input tray material | metal |

| Material of knife, discs | stainless steel |

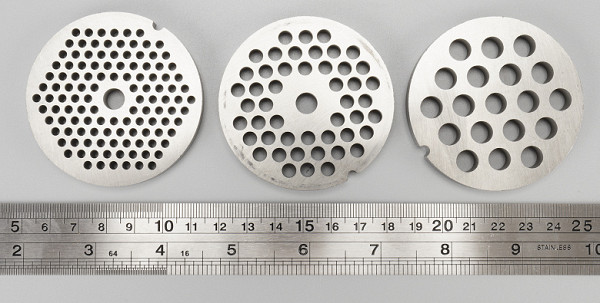

| Number of disks | 3 pcs: 3mm, 5mm, 8mm |

| Screw material | silumin |

| Maximum cookware height | 11 cm |

| Additionally | reverse |

| Protection | from overheating, from overload |

| Accessories | meat grinder block , disks for minced meat (3 pcs.), device for cleaning disks, pusher for meat grinder, loading tray, nozzle for kebbe, nozzle for preparing sausages (3 pcs.), vegetable cutting unit , grater attachments (3 pcs.), shredder attachment, attachment for potato pancakes, pusher for vegetable cutter |

| Net weight fully assembled | 4.64 kg |

| Dimensions when fully assembled (W×H×D) | 347×309×178 mm |

| Network cable length | 1.5 m |

* Contrary to popular belief, this is not the time limit after which the device will necessarily break down. However, after this period, the manufacturer ceases to bear any responsibility for its performance and has the right to refuse to repair it, even for a fee.

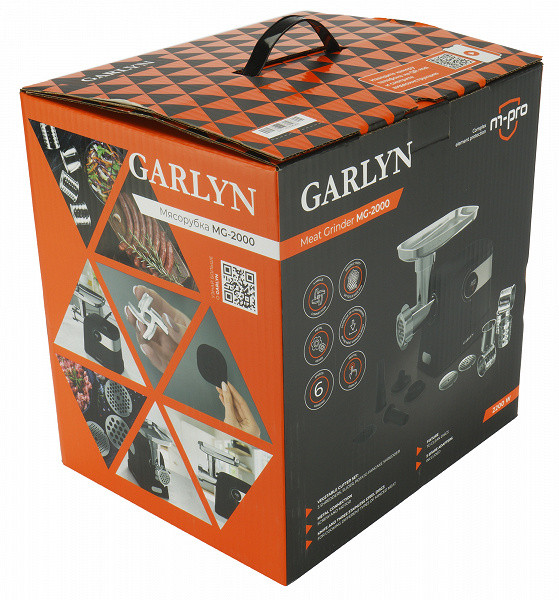

Equipment

The Garlyn MG-2000 meat grinder was delivered in a compact box made of durable cardboard with bright color printing. On the front and back sides of the package there are photographs of the meat grinder itself in a corporate design, as well as a description of its key features. On the side faces you can find detailed information about the device’s configuration and technical characteristics.

For ease of carrying, the box is equipped with a plastic handle. Inside, the components and the meat grinder itself are placed in plastic bags and securely fixed with inserts made of durable pressed cardboard.

Garlyn MG-2000 kit includes:

- Motor block

- Meat grinder block

- Loading tray

- Pusher for meat grinder

- Auger

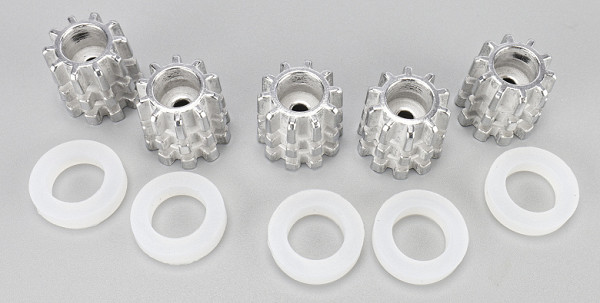

- Replacement adapters (6 pieces)

- O-rings (6 pieces)

- Screw for fixing the replacement adapter

- Meat grinder knife

- Fixing ring

- Perforated disks for minced meat (3 pieces)

- Attachments for preparing sausages (3 pieces)

- Kebbe attachment

- Base for sausage and kebbe attachments

- Vegetable cutter block

- Pusher for vegetable cutter

- Grater attachment (3 pieces)

- Shredder attachment

- Attachment for potato pancakes

- Device for cleaning meat grinder discs

- User manual, quick instructions and warranty card

At first sight

The Garlyn MG-2000 meat grinder in a compact case with rounded corners looks laconic and stylish. The surface of the motor block is made of non-marking black matte plastic.

A metal plate surrounds the upper part of the body. It houses a single control element in the form of a round speed controller with a built-in LED display.

Half of the top part of the body is the lid. Behind it there is a fairly deep compartment for small attachments.

All of them won’t fit there, but in any case, the ability to store at least some small items compactly and not have to look for them throughout the kitchen on occasion is wonderful.

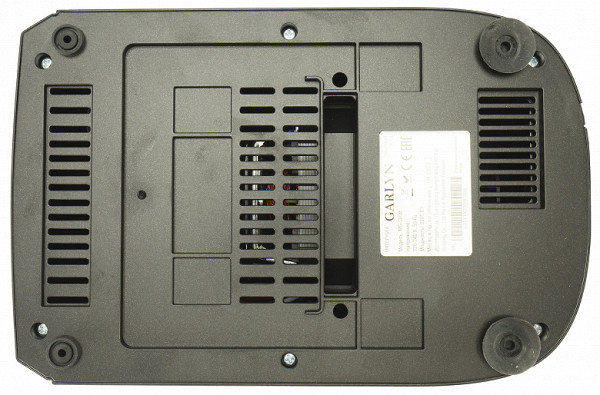

The heavy body of the device is securely held on the table. Its stability is ensured by both its own weight and four legs, two of which are equipped with suction cups. There are also ventilation holes and a label with technical information on the bottom of the device.

A cord 1.5 meters long comes out of the back wall.

A meat grinder block of a standard design consists of: a neck, a screw, a knife, a grid and a ring nut securing the structure. The ring is quite large, with protrusions for easy unscrewing.

The meat grinder screw is equipped with a metal (probably made of silumin) overload fuse and a silicone sealing ring. The fuse is designed to absorb shock in the event of contact with broken bones or fruit seeds. The delivery set includes a spare fuse in the amount of five pieces, which demonstrates a high level of care for the consumer on the part of the manufacturer.

The knife and disks for preparing minced meat are massive, thick and very well sharpened. The discs have holes of 3, 5 and 8 mm.

The block is inserted into the socket at an angle of 45 degrees and is fixed by turning counterclockwise until it clicks.

To unlock the nozzle, press the lock button located above on the left.

The spacious tray for feeding prepared products is made of aluminum, and the pusher is made of plastic.

The kit includes a special device for cleaning the grilles. This tool is a rubber die with two sides designed for large and medium-sized grates, respectively. Although the idea is good, it would be better if the fingers were rigid, which would make the process of aligning with the holes faster.

In the photo below we see plastic nozzles for sausages: 20, 15 and 11 mm. Below them: a kebbe attachment and attachment bases for installing them on the meat grinder block.

The vegetable cutter consists of a body, a pusher and replaceable attachments.

The block is attached to the body in the same way as the meat grinder block. The dimensions of the loading hole are 5x4.6 cm. Nozzles can be changed without disconnecting the unit from the device body.

The vegetable cutter comes with five attachments: three graters of various sizes, a shredder attachment and a hash brown grater. The diameter of the cylinder is 6 cm. The quality of metal processing is excellent, and the cutting edges of the nozzles are very sharp.

Disassembly

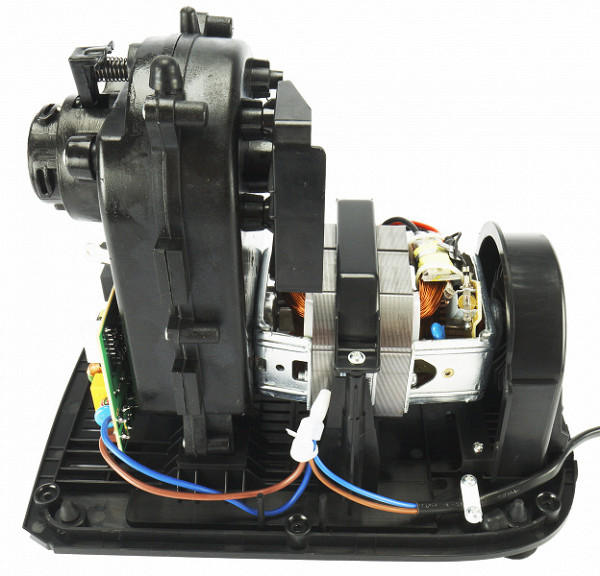

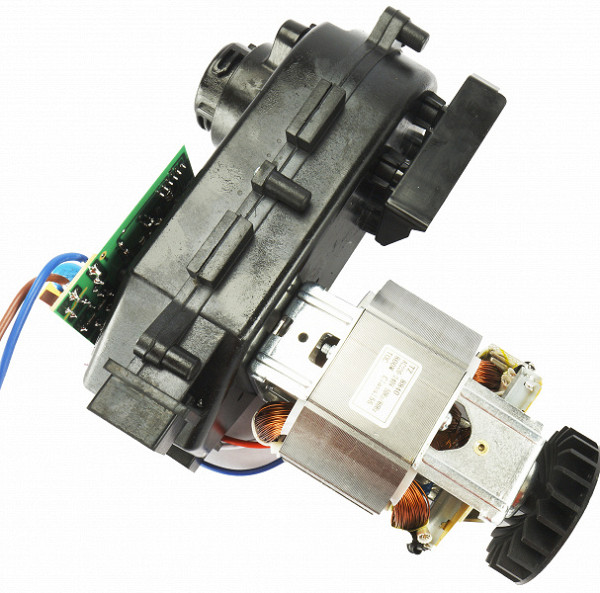

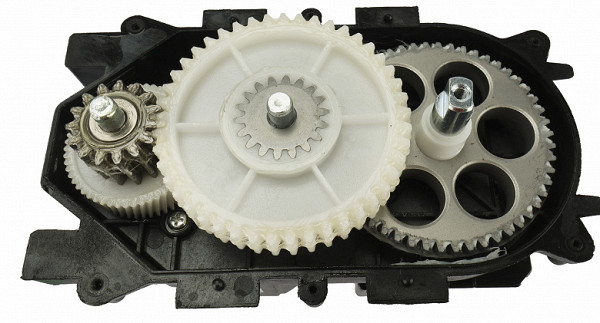

Inside you can see that the gearbox is placed in a separate housing, which provides additional protection from accidental damage and foreign particles. If necessary, the gearbox housing can be disassembled.

The internal structure is without surprises: an electric motor and a cooling fan impeller. Wired connections are made neatly.

Motor number and specifications — this data may be useful if replacement is needed.

The meat grinder gearbox has a traditional design and consists of three gears. The amount of lubricant is sufficient.

Instructions

The set of documents includes brief instructions, a warranty card and a detailed 23-page instruction manual. All documents are made in the same corporate style and printed on high-quality glossy paper.

The manual contains detailed information about the device, its functions, safety precautions, as well as tips for care, storage and troubleshooting. The text is written in simple and understandable language, complemented by illustrations.

Control

The Garlyn MG-2000 meat grinder is controlled via a round rotary and push control. After connecting to the network, a power-on indicator will appear on the display built into the controller. To start the operation, press the regulator like a button. An indicator with a zero value will appear on the display, which can be changed to the appropriate number by selecting the desired speed.

When you turn the knob to the right, the speed increases from 1 to 6, and when you turn it to the left all the way, the reverse starts — the reverse rotation mechanism. This feature can be useful if food gets stuck inside the meat grinder. To turn off the meat grinder, simply press the regulator again.

Exploitation

Before first use, thoroughly wash and dry all attachments and accessories, and wipe the body with a damp and then dry cloth. Then you should assemble the structure in accordance with the instructions and you can begin work.

Assembling and disassembling both the meat grinder and the vegetable cutter is quite simple and does not cause any difficulties. Operating the equipment is simple and convenient.

However, none of the tests were able to achieve the performance stated in the promotional materials. The meat grinder turned out to be somewhat slow, and when disassembling, sometimes whole pieces of meat could be found. More information about this can be found in the description of practical testing.

It is also worth noting that at speed 6 the device sometimes turns off due to overheating protection.

If such a situation occurs, you can briefly unplug the meat grinder and then turn it on again. After this, it will usually continue to work as normal without any problems. It is important to note that despite periodic shutdowns, the quality of the finished minced meat remains decent, and no unground pieces are found in it.

The vegetable cutter works flawlessly. Shredding and graters produce high-quality results at a moderate speed and with a minimum amount of waste.

The noise level at 5-6th speed is rated as high. During operation, the device remains motionless and does not vibrate. However, it is recommended not to exceed the permissible continuous operation time of 15 minutes, after which the device requires a 30-minute break. The instructions strictly do not recommend chopping bones, skins, frozen or coarsely chopped meat, nuts, ginger and other dry and hard foods.

Care

It is recommended to wipe the body of the meat grinder with a damp cloth, and all removable parts should be washed under running water using a neutral, non-abrasive detergent. After washing, wipe dry. The plastic sausage and kebbe attachments, as well as the vegetable slicer pusher and disc cleaner are dishwasher safe up to 60 degrees.

Our measurements

The maximum power of the grinder was recorded when processing tough beef and was 396 W, while the minimum power achieved when chopping cucumbers was 118 W. On average, the power ranged from 120 to 280 W.

For 2 minutes 45 seconds, when 1 kg of beef was processed, the meat grinder consumed 0.016 kWh, and for processing 1 kg of pork ham for 1 minute 40 seconds, 0.013 kWh was spent.

The noise level during processing of pork ham at 6th speed was 85 dBA.

Practice tests

Standard testing

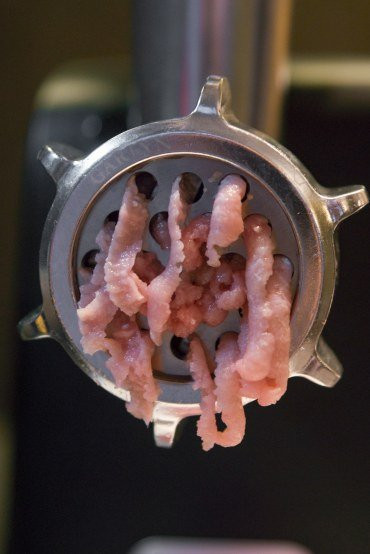

The first, traditional and mandatory test is minced pork ham.

We rolled one kilogram of chilled meat, cleared of films and veins, through a grill with medium holes at speed 6.

During the process, we constantly used a pusher, otherwise the pieces were reluctantly captured by the auger. The minced meat itself is crumbly; we did not find a single whole piece in it.

An unprocessed piece weighing about 20 g was waiting for us in the meat grinder body. During the process, it wound around the auger, which negatively affected the result.

The performance factor for the Garlyn MG-2000 was 600 g/min.

For comparison, we tried rolling the same meat through a large grill.

60 g of meat has accumulated behind the knife. Not coiled veins or fibers, but just a large whole and several small pieces.

Minced stringy beef

For this test, we took stringy beef of the third grade — beef trimmings with a large number of films and veins.

We used a medium grille and started at 6 speed, using the pusher the entire time.

After 40 seconds, the meat grinder stopped working and the message “Err” appeared on the display. The surface of the motor block remained cool and there was no foreign smell.

We hastened to unplug the device, gave it a 10-second rest and turned it on again, but, just in case, at 5th speed. The overload protection no longer worked.

As a result, 1 kg of meat was processed in 2 minutes 45 seconds (363 g/min) without taking into account the reloading stop.

The speed is low, but the grinding thoroughness is acceptable. Well-chopped minced meat did not contain whole fragments of meat.

Sausage stuffing

We took half a kilo of minced meat from previous tests, added a mixture of ground coriander, white pepper and dried garlic. Add salt, mix thoroughly and put it in the refrigerator to infuse. When the minced meat was ready, we installed the largest sausage attachment with a diameter of 20 mm on the meat grinder block, stretched a natural collagen casing over it and stuffed almost 3 meters of sausages at first speed. The process was easy, the minced meat was perfectly pushed into the neck and easily filled the shell.

When disassembling the nozzle, a total of 110 g of compressed minced meat accumulated in the auger and in the plastic cone.

Result: excellent, if not for the amount of waste

Cabbage

The cabbage was cut into bars that fit freely into the neck.

We attached a vegetable cutter attachment to the motor block and inserted a drum shredder, then turned on the device at first speed. Gradually feeding a stack of leaves into the neck, we pressed them down with a pusher. There was no need to stop work and remove the compressed pieces from the inside of the drum, since under the pressure of a new portion of chips coming out of the nozzle, they fell out on their own.

The shredder is excellent, all the slices are the same size. Waste — one torn sheet and a couple of scraps.

Result: excellent

Radish, cucumber and carrots

We tested the medium grater on radishes and cucumbers.

The vegetables were quickly and evenly chopped into neat, thin shavings, and when disassembling the attachment in both cases, there was very little waste left in the form of unprocessed skins. During operation, the device did not throw chips beyond the placed plate, even when operating at high speed.

We grated the carrots on a drum with the smallest holes and again got an excellent result.

Result: excellent

conclusions

The Garlyn MG-2000 meat grinder is easy to use, easy to operate and easy to assemble and disassemble. The stable housing with suction cups prevents the device from moving during operation, even with intensive use. The compact size of the device saves space, and the spacious accessory container provides convenient storage. The equipment also deserves attention: in addition to three standard discs for minced meat and attachments for sausages and kebbe, the kit includes a vegetable cutter attachment with five cylinders for various processing of vegetables, as well as fuses for the meat grinder auger.

Despite the obvious advantages, the compactness of this model comes at a price. During meat processing, we received high-quality minced meat without large pieces, but the speed of the meat grinder turned out to be below average. At the same time, the vegetable cutter attachment did not cause any complaints and did an excellent job of finely chopping and grating fresh vegetables.Despite the obvious advantages, the compactness of this model comes at a price. During meat processing, we received high-quality minced meat without large pieces, but the speed of the meat grinder turned out to be below average. At the same time, the vegetable cutter attachment did not cause any complaints and did an excellent job of finely chopping and grating fresh vegetables.

Pros:

- Stylish body and neat assembly

- ease of use and maintenance

- compactness and storage compartment for accessories

- wide range of equipment

- replacement fuses for meat grinder auger

- convenient and efficient vegetable cutter

Minuses:

- low speed of meat processing

- The meat grinder periodically stops due to overheating when operating at maximum speed