Each type of tool is designed for certain types of work, and this statement is difficult to refute. While cordless tools are ideal for quick, small-scale work, a chainsaw can be used for cutting firewood even at an industrial level. However, the high power and autonomy of the chainsaw have its own characteristics: heavy weight, high noise levels and possible pollution. These are the common beliefs. However, I wonder how modern chainsaws correspond to these stereotypes?

Characteristics

| Manufacturer | Geos (Al-Ko) |

|---|---|

| Model | Geos Max CSP137 |

| Type | gasoline chain saw |

| engine's type | petrol two-stroke 36 cm³ |

| Power | 1.5 kW (2 HP) |

| Engine speed, rpm |

|

| Carburetor | Walbro |

| Tank volumes |

|

| Type of fuel | fuel mixture (50 parts unleaded gasoline with an octane rating of at least Au 90 and one part Al-Ko synthetic two-stroke engine oil) |

| Chain pitch (sprockets) | 3/8″ Low (low profile) |

| Chain, working link thickness | 1.3 mm (0.050″) |

| Number of links | 53 |

| Guide bar length | 35 cm (14″) |

| Chain speed, max. | 22.86 m/s |

| Dimensions, weight | 5.38 kg with empty tanks, with bar and chain |

| Other characteristics |

|

Characteristics

The saw is delivered in a cardboard box in disassembled condition.

The chain saw is supplied with a saw chain with a bar and a protective cover, a special combination key for accessing the spark plug and tensioning the chain, a screwdriver, a file for sharpening the chain teeth and user instructions.

A knowledgeable craftsman will instantly figure out what is screwed here and where, but we will not rush.

Design, control

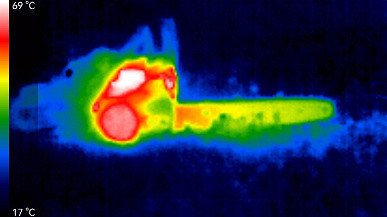

The body of the chain saw, made of high-quality, high-strength polymer, almost completely covers the engine. The only element exposed is the muffler, the hottest component of the engine, facing forward.

The classic design of the chainsaw is most convenient for use by right-handed people. This is indicated by the location of the front tubular handle, positioned to the left.

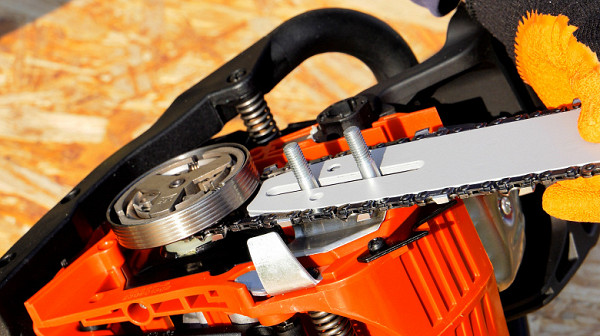

One of the key components of a chainsaw is the saw chain and the bar on which it runs. Many chainsaw models use a tool-free method for adjusting chain tension. However, in this case, to install the bar and correctly tension the chain, as is common in many professional models, a special combination wrench is required, included in the package.

The chain oil tank for automatic chain lubrication is located at the front, while the fuel mixture tank is located closer to the rear handle. Between them, in the middle of the panel with ventilation holes, is the starter handle.

Behind this handle there is an important element — the air damper control lever. It is used when starting a cold engine.

The fuel mixture tank is equipped with a translucent window that allows you to control the mixture level. Unlike it, the oil container does not have such a window, but this is not a problem. It is enough to check the oil level every time the fuel in the tank runs out. The developer has provided a smart ratio of chain oil and fuel consumption: fuel is always depleted faster than oil. Provided that both tanks were initially filled to capacity.

On the rear control handle, on the operator's side, there are two main controls. To the left of the handle there is a «Stop» button, which is used to stop the engine. This button is spring-loaded and does not lock in the “0” position. When you press it, the engine turns off, and when you release the button, it returns to its original state, placing the unit in the “Ready to Start” mode. This makes the startup process much easier for the user. The second control element is a manual fuel pump, designed to pump fuel when starting a cold engine. A transparent cap is installed on the top of the pump to monitor the fuel filling level.

The main controls are located on the rear handle, as you'd expect. There are two buttons here. The bottom button is the throttle lever, and the top button serves as a safety lock or safety lock. Until the top button is pressed, the throttle lever will remain locked.

The chain brake lever, despite its name, is a large platform. This control element in chain saws is always large in size so that the operator, if necessary, can quickly stop the rotation of the chain by pushing the chain brake lever away from himself. In addition, sometimes the chain brake lever may be activated automatically, for example, when the end of the bar collides with an obstacle, when it falls, or when the saw body suddenly moves towards the operator. In such situations, inertia causes the lever to swing forward, causing the chain to stop instantly.

By the way, the mechanism that brings the chain to a stop, although simple in design, requires some skill during installation. More on this below.

Every chain saw has a toothed stop. Most of these tools are equipped with a metal stop with sharp teeth. These teeth are necessary to securely hold the saw in one position when cutting loose round branches or logs. Our saw also has a metal toothed fence, as well as an additional plastic fence on the side. The plastic stop is supposed to be used when working with soft materials, such as rotten logs. When the metal teeth of the fence penetrate completely into the material, the plastic fence provides additional support and security. This results in double protection.

After completing the external inspection of the instrument, we proceed to checking the units. To access the filter and spark plug, simply remove the top cover of the unit using the included combination wrench. It is secured with two metal brackets located on the sides of the case.

Maintenance of the spark plug and air filter requires infrequent intervention. These components are protected by a secure cover that prevents dust and debris from entering. However, the air filter should be cleaned periodically, since air passes through it, which is necessary for the correct enrichment of the fuel mixture. Lack of oxygen can cause engine problems.

At first glance, installing a bar with a saw chain seems simple. However, not only is it necessary to install the bar on two metal pins and route the chain around the drive sprocket, but also to properly configure this process for optimal operation of the tool.

Maintenance of the spark plug and air filter requires infrequent intervention. These components are protected by a secure cover that prevents dust and debris from entering. However, the air filter should be cleaned periodically, since air passes through it, which is necessary for the correct enrichment of the fuel mixture. Lack of oxygen can cause engine problems.

At first glance, installing a bar with a saw chain seems simple. However, not only is it necessary to install the bar on two metal pins and route the chain around the drive sprocket, but also to properly configure this process for optimal operation of the tool.

As a result, all this is fixed with the side cover of the drive sprocket and screwed with two nuts, the so-called “non-losing nuts”.

Installing the cover does require some dexterity. However, it is easy to check that the installation is correct: just move the chain brake lever towards the operator and lightly pull the chain in any direction. When installed correctly, the chain should move freely, and when the brake lever is pressed away from the operator, its movement should be completely blocked.

When installing a bar with a chain, it is also important to observe the correct direction of movement of the cutting teeth, which is indicated on the pictogram on the body of the chainsaw and on the bar itself. It's impossible to make a mistake here.

The chain tension is adjusted using a screw. It's quite simple: the tighter the screw is, the tighter the chain is.

The optimal chain tension is easy to check. First, the chain must fit snugly to the bar without creating sagging. Secondly, the chain must move easily along the bar using your hand. If the chain is too tight, like a string, it can put unnecessary stress on the motor and quickly overheat the structure.

The saw is almost ready for use, but not completely. Without chain oil and fuel mixture (a mixture of gasoline and motor oil), it remains incomplete. To achieve optimal results in testing, we were provided with special branded fluids: chain oil and two-stroke engine oil.

The first liquid is chain oil. The capacity of the saw tank is about 230 ml. However, this is no ordinary oil — it is a mineral adhesive oil designed specifically for chainsaws. It has unique properties: it does not spread or splash during operation, even when heated. The oil remains fluid even at low temperatures and is evenly distributed throughout the chain links and bar. It only takes a few seconds of engine operation to ensure that the chain and bar are sufficiently coated with a thin layer of oil.

To 92-octane gasoline, add high-quality synthetic motor oil for two-stroke engines in a ratio of 50:1 (50 parts gasoline to one part Al-Ko synthetic oil). The resulting mixture must be thoroughly mixed before pouring into the fuel tank.

Finally, the saw is completely ready for use. However, there are a few more subtleties that everyone who has ever worked with a gasoline tool knows about.

Exploitation

To start a cold engine, you need to force fuel into it using a special pump, or primer, which is located to the right of the main handle on the engine block. After pressing the transparent pump button approximately five times, its container will be filled with fuel, and you can start starting by pulling the starter handle.

When starting a cold engine, it is also necessary to close the air damper located on the left side of the housing behind the starter handle. Subsequently, when the engine is already warmed up, there is no need to touch this handle, since the engine will start with half the stroke of the starter handle.

When using a tool that may pose a risk of injury, safety precautions must be followed at all times. It's similar to driving a car on the highway, where every second counts. For example, when working with a saw, it is necessary to correctly orient the direction of the cut and take into account the applied force in order to avoid injury to the operator’s legs from a suddenly released saw. It is also important to be aware of possible hazards from falling branches or trunks that could injure the operator.

When sawing hardwood, engine power plays a key role. It is undesirable for the saw to “freeze” when faced with strong resistance. Let's check how the saw in question copes with high loads. We do not have access to or permission to freely process South American woods such as jatoba or other exotic species. However, we have access to cherries and apples that require little processing.

When working with such types of wood, it is clear that the saw copes with them easily. Branches or trunks are sawed through in a matter of seconds. However, more time is spent choosing a comfortable working position.

In addition to maintaining the garden, we made several observations. It is important to note the low noise level created by the operating saw. Typically, gas saws (and other gas powered tools) produce a harsh, loud engine sound that requires the use of hearing protection. However, there is no such noise, even when operating at high speeds. Apparently this is the result of using an effective muffler?

Yes, that's probably true. In addition, the direction of gas emission from the muffler is also optimally chosen.

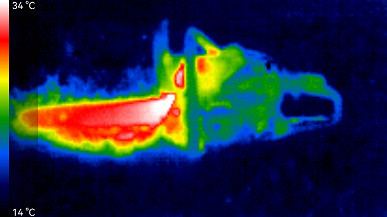

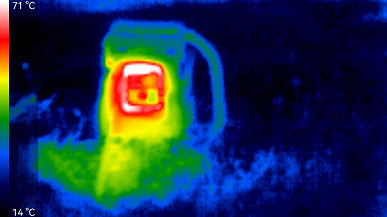

The muffler is directed forward, away from the operator. This can be seen even from thermal imaging images, from traces of heating on the ground from the emitted gases. The main part of the sound signal also “flies” there, forward (but we cannot see it directly). Thus, the risk of exhaust gas poisoning during prolonged operation is reduced to almost a minimum, and the likelihood of hearing damage is also reduced. However, do not forget that using gas-powered tools in enclosed spaces is still not recommended.

And the second important observation: where is the vibration? There is practically none. When you hold our saw with the engine running, the strong vibrations typical of gasoline saws are almost not felt. The secret is simple: upon visual inspection of the saw, you can notice several springs on which the engine block seems to be suspended. It turns out that not only springs are used here, but also anti-vibration pads, similar to those that are sometimes installed for external units of air conditioners.

Thus, the saw is structurally composed of two almost independent units: a platform with a main handle and a front tubular handle, and a motor unit with a bar and chain, which floats on springs attached to the platform.

It seems that the shock absorbers travel is small, only a few millimeters. But in operation they effectively soften vibration, as was demonstrated in the previous video.

I would like to find out how long the saw can operate with a fully filled fuel tank. Let us remember that the tank holds 0.27 liters of fuel mixture. This may not seem like much, but it can be enough for a long run.

It would also be a good idea to know how the saw handles cutting thick logs. To do this, we decided to use a sawmill, which had accumulated a lot of wood from dismantled log cabins, which we plan to saw into firewood. Although we did not find enough logs, this experiment will still give us an idea of the autonomy of the saw.

Conclusion: In seven minutes of leisurely work, more than a dozen cuts of large logs were completed, which consumed about a third of the filled fuel tank. This means that a full tank of fuel should theoretically last for half an hour of leisurely operation. This is a very satisfactory indicator, which allows you to free a considerable area from bushes and trees or to prepare enough wood for subsequent use in the form of firewood.

In addition, the results obtained are quite consistent with standard indicators. Average fuel consumption for chainsaws, calculated by developers and users, varies from 0.7 liters per hour for 1.5 kW motors (as in our case) to 3 liters per hour for 4.5 kW models.

Another important observation: during operation, the saw does not deviate from a straight cut, without going to the side or at an angle. This is especially noticeable when cutting thick logs, even in cases where the placement of the logs creates inconvenience. This indicates the high rigidity of the tire and the entire structure of the saw as a whole.

Finally, we should mention the bar length of our saw. The bar, complete with a saw, has a length of 35 cm, but in fact its working length is slightly less, about 33 cm. This allows you to easily saw logs or trunks up to 66 cm thick when filing them in a circle. If the log is thicker, it can be sawn on both sides.

Care

In addition to superficial cleaning, the chain saw requires careful maintenance. The saw chain, being in direct contact with the wood, accumulates various contaminants inside it. Chips, dust and chain oil are mixed into a thick paste, which is still compacted at high chain speeds. This slurry must be removed after each use of the saw using a stiff, non-metallic brush.

conclusions

The Geos Max CSP137 chainsaw is ideal for everyday or occasional work that does not require professional level power. It does not claim to have the highest power, but for the average user this is not a decisive factor. For such people, other characteristics of the tool, such as compactness, efficiency, durability, reliability and safety, are more important. All these qualities are completely inherent in the saw in question:

- Compact and durable design, light weight.

- Anti-vibration system.

- Simple and convenient controls.

- Simplified engine starting system.

- Cost-effective.

- Automatic control of chain lubrication and fuel supply.

- Quick installation of the bar and chain.