Garlyn surprised with innovation in the design of the meat grinder, adding a color display and automatic attachment of attachments to its body. While the promise of performance up to 4kg/min is questionable, the functionality of the attachments and attachments included in the Garlyn Grind Pro kit promises to be a fun testing experience.

The author is looking forward to interesting research with a vegetable cutter, juicer and burger maker. We intend to test their basic and additional functions, as well as ease of use, including automatic attachment of attachments and touch controls with a display.

Characteristics

| Manufacturer | Garlyn |

|---|---|

| Model | Grind Pro |

| Type | electric meat grinder |

| Country of Origin | China |

| Guarantee | 12 months + 12 months extended warranty |

| Device service life* | 3 years |

| Declared power | nominal — 500 W, maximum — 3000 W |

| Housing material | metal |

| Case color | silver |

| Removable head material | aluminum |

| Blade and grate material | stainless steel |

| Knife gratings | two included: with large (7 mm) and medium (5 mm) holes |

| Grating diameter | 60 mm |

| Cord storage compartment | No |

| Accessory storage compartment | separate container |

| Meat grinder neck height | 9.5 cm |

| Maximum height of the minced meat container | 13 cm |

| Control type | electronic |

| Number of speeds | six |

| Reverse | There is |

| Auger speed | 100 to 200 rpm |

| Overload protection | There is |

| Additional accessories included | two attachments of different diameters for making sausages, an attachment for making kebbe, a vegetable cutter attachment with three cylinders: grater, shredding and slicing into thin slices, an auger juicer attachment, a collapsible burger press, a device for cleaning the grinder grates, a container with a lid for storing accessories |

| iXBT.com performance coefficient based on test results (disc with large holes) | 1.2 kg/min. |

| Assembly weight of the meat grinder | 6.4 kg |

| Dimensions of the assembled meat grinder (W×H×D) | 34×30×18 cm |

| Network cable length | 1m |

* To put it very simply: this is the period during which parts for repairing the device are supplied to official service centers. After this period, any repairs in official service centers (both warranty and paid) are unlikely to be possible.

Equipment

Our work sometimes turns into a real holiday, especially when it comes to the Garlyn Grind Pro meat grinder. Its design is so attractive that you can safely give it to your wife on March 8, especially if you add a mimosa sprig and a flirty bow to the gift. This gift can provide a man with cutlets and sausages for some time.

The device comes in brightly designed packaging that attracts attention. The information on the packaging is complete and informative, allowing the buyer to become fully familiar with the advantages and technical characteristics of the device. The box is made of durable corrugated cardboard and equipped with a convenient carrying handle.

The interior of the box is organized to the smallest detail using various packaging materials: cardboard inserts, foam stoppers and individual boxes. After disassembling the package we found the following components:

- Motor block.

- Assembled meat grinder unit, including body, auger, knife, medium-sized grid and fixing ring.

- Grate with large holes.

- A container for storing accessories with a lid, inside of which there was a loading tray and a pusher for the meat grinder.

- Attachments for making kebbe and two attachments for forming sausages of different diameters.

- Vegetable cutting unit, including a body, a pusher and three cylinders: fine and coarse graters, shredder.

- Assembled unit of the juicer attachment.

- Device for cleaning perforated grilles.

- Burger press.

- Operating instructions, warranty card and quick start guide.

At first sight

The Garlyn Grind Pro meat grinder has an unusual body shape: a wide base 2 cm thick, on which a motor compartment with variable width is located. The weight of the device without attachments is quite significant — 5.8 kg. Thanks, perhaps, to these parameters together, the body is securely held on the surface and moves with difficulty.

The body is made of metal, the silver color looks neutral and noble. There is a control panel at the top of the front, and attachments are connected on the left side.

A standard power cord connects to the bottom of the right side of the chassis. Its length of 1 meter seems sufficient for using the device at home. At the top of the case there is a plastic plug with ventilation holes.

At the bottom of the meat grinder there is a label sticker with brief information about the device, as well as four legs with rubber suction cups with a diameter of 3 cm. These suction cups securely fix the body, preventing it from sliding and absorbing vibrations, as noted above.

Without connecting the device to the network, you will not be able to connect attachments. But you can see the drive shaft and spring in depth. Both the drive shaft coupling and the shaft itself are metal.

The body of the meat grinder attachment is made of aluminum alloy, and the knife and perforated grids are made of steel. All metal parts are processed with high quality, their surfaces are smooth and free of nicks or traces of processing. The body has a standard and compact length, which makes it easy to care for — even the sponge easily reaches the back of the inner walls of the nozzle.

The set includes two perforated grilles with holes with a diameter of 7 and 5 mm. Particular attention should be paid to the knife: it has a double-sided sharpening, so care is required when working with it — the sharpening is done with high quality, the blades are very sharp.

Moving on to the additional accessories, the body of the vegetable cutter attachment and the pusher are made of black plastic in a standard shape. The diameter of the loading hole is 5.5x6 cm, which will not allow you to easily process large volumes of cabbage, but will cope with smaller vegetables, fruits and cheese without preliminary chopping. Large carrots and cucumbers fit into the hole, although large potato tubers require preliminary cutting into 4 parts. Assembly of the nozzle is easy: the cylinder is inserted into the body so that the holes on its bottom correspond to the protrusions on the rear wall of the body, and rotated slightly clockwise.

Three metal drums provide the ability to slice, chop and grate food for further processing. The metal sheet of the drums is thick and is not subject to deformation when pressed hard. The cutting edges are very sharp, so be careful when handling the attachment.

The juicer attachment has a standard auger design, consisting of several parts that are easily connected to each other in an intuitive way. All parts, with the exception of the metal rear part of the auger and the perforated sieve insert, are made of plastic.

Through the transparent case, the user can conveniently observe the process of processing fruits and berries. The diameter of the loading opening of 5 cm corresponds to the size of the loading opening of the meat grinder, which allows you to use one pusher for both attachments.

We admire the concern for user comfort — the device comes with a spacious container measuring 14x22.5x10.5 cm with a lid for storing accessories. It can easily accommodate, for example, a loading tray. The tray is made of metal, low and securely fixed to the loading opening, ensuring stability during operation.

The container can also store additional Garlyn Grind Pro accessories, such as pushers, kebbe and sausage makers, and a burger press. These parts are made of black plastic and have a standard shape. It is worth noting that there are two forming attachments for sausages: one with a diameter of 2 cm, and the other — 2.5 cm.

The attachment for preparing burger patties promises to be very convenient. With its help, you can create cutlets of two different diameters: 10 or 7 cm. Each accessory consists of a molding ring into which a bottom and a press with a handle are inserted. The press fits into a mold with a larger diameter. Turning the handle of the press in the direction indicated removes the outer plug, and the inside of the press can be used to compact the mince into a small form or to press out a cavity for the filling when cooking immediately. Overall, this accessory promises to be very useful and easy to use.

We were unable to disassemble the meat grinder to closely examine its insides. The screw plugs on the back of the case were either glued or had a particularly complex shape, and we couldn’t even remove them — we only damaged their appearance.

However, we were persistent, so we unscrewed the bottom of the case and tried to look into the narrow hole filled with wires and other radio components.

In the depths of the meat grinder, you can discern a motor to which a planetary gearbox in a plastic casing is attached. On the front wall you can see the mechanism for automatically fixing the attachments. We couldn't see more.

We were pleased with the results of our visual inspection of the Garlyn Grind Pro meat grinder. The device gives the impression of being well made and very interesting.

Instructions

The kit contains three A6 documents: a user manual, a warranty card and a one-page memo. All documents are distinguished by high-quality printing and the use of good paper. A special note should be highlighted: on two sides of a thick glossy sheet, the manufacturer has placed the most important information about the design of the product, including the names of all parts and components, operating and safety rules, as well as control features. This leaflet is a condensed extract of useful information from the user manual. If you have questions about operation, you can refer to the main manual. However, if everything is clear, studying the leaflet will give you all the information you need to get started. In our opinion, this is simply perfect.

The information in the user manual is presented consistently, logically and clearly. It describes in detail all aspects of interaction with the device and its accessories, including a section devoted to possible malfunctions and how to eliminate them. In general, the rules for working with the Garlyn Grind Pro meat grinder are standard, but to use additional attachments you may need to refer to the instructions. Therefore, it is recommended to keep the document at hand, especially during the initial period of operation.

Control

One of the most exciting moments when using the Garlyn Grind Pro meat grinder, according to the author, is its control. The control panel with touch buttons and display is something unusual for a meat grinder. How justified such a design is is a matter of preference and taste of the end user, but it certainly looks impressive.

When the device is connected to the network, one short beep sounds, the panel lights up for a few seconds, then goes out, and only the power button remains brightly illuminated in red. After clicking on it, a request appears on the display to attach the nozzle — after all, the device will not be able to work without it.

After attaching the nozzle, everything becomes intuitive and expected. Simply select the desired operating speed using the "+" and "−" buttons, then press «Start». To stop the process, just click on the “Stop” button. The operating time will be shown in the upper right corner of the display. If you need to disconnect the attachment, simply press the “Lock” button. Despite the author's personal dislike for electronic controls, he admits that the touch panel is much more convenient than smooth mechanical handles, which can get dirty when working with minced meat.

As for the display, when switching speeds, a corresponding picture appears on the screen and a recommendation for which operation the selected speed mode should be used.

The meat grinder is equipped with six speeds. The first three are for squeezing juice and chopping vegetables, and the tall three are for chopping meat. The controls are simple and intuitive: the buttons respond adequately to pressing, all functions are labeled and obvious. The bright display and luminous elements provide excellent visibility even in direct sunlight.

Exploitation

Before use, we carried out the necessary preparation procedures: wiped the body with a damp cloth, washed all removable parts in warm water with detergent, wiped and dried them thoroughly, and then assembled all the attachments.

Assembly and disassembly of both the main and additional attachments did not pose any difficulties. All manipulations took place in a standard manner, and the parts were connected to each other in an expected and understandable way.

The attachments were fixed on the body using the “Lock” button. The inability to mechanically remove or secure attachments with the design of the motor unit raised certain doubts. However, during use there were no problems with fixing the attachments. The attachment was removed and put on exactly when required.

Let's note a few key points:

- Convenient use of a standard power cord: no need to roll anything up for storage, it can be easily connected or disconnected at the right time.

- Reliable fastening of the case: during operation it does not move even a millimeter thanks to the suction cups, which do an excellent job of their function.

- Requirements for the preparation of raw materials: standard and clear, which facilitates the preparation of products for processing.

- Continuous work time: limited to five minutes followed by a break. Our experience has shown that this is sufficient time for most tasks.

- Convenience of attachments for making sausages: the presence of two attachments of different diameters makes them universal and easy to use.

- Vegetable cutter: made working with vegetables a pleasure, reducing the time for preparing them.

- Juicer and burger press: successfully fulfilled their functions, adding convenience to the use of a meat grinder.

In conclusion, Garlyn Grind Pro left us with a favorable impression. It is easy to use, has multiple speeds and functions, while delivering excellent results. The only question is the convenience of automatically fixing the attachments in the long term.

Care

To care for your Garlyn Grind Pro, we recommend the following: Clean the device immediately after use. The plastic parts, including the cleaning device, can be washed in the dishwasher at a maximum temperature of 60 °C. Metal accessories should be cleaned with a sponge using a mild detergent and then dried until completely dry to prevent corrosion. It is recommended to wipe the housing and control panel with a damp cloth. Avoid using harsh detergents, abrasive cleaners and wire brushes.

To remove food residues from the holes in the perforated grill, use the special tool included in the kit. Place the disc to be cleaned on the device, remove any remaining minced meat and rinse the disc under soapy and then running water. Then turn over the disc to be cleaned and repeat the above steps.

To remove colored deposits from the plastic parts of the vegetable cutter that have arisen after chopping carrots, use a cotton pad soaked in vegetable oil. A small amount of vegetable oil is recommended to protect the metal parts of the meat grinder from rust.

Our measurements

The maximum power of the Garlyn Grind Pro meat grinder was recorded when processing stringy beef through a grate with a large diameter of holes at a maximum speed of 308 W. On average, when preparing minced meat from more suitable raw materials, the motor power fluctuated around 180 W.

We exceeded the maximum permissible continuous operation time only when working at low speeds when squeezing juice, but we were not able to cause the case to heat up and trigger the M-Pro's automatic shutdown function. It was also not possible to exceed the operating time at high speeds when chopping meat — the productivity of the device is so high that in five minutes you can grind minced meat for the canteen of a small candle factory. While stuffing the sausages, the meat grinder worked for a little over 40 minutes with short pauses to stretch the casing and tie the ends.

We rated the noise level as low for a meat grinder: no roar or howl of the motor — quietly, quickly and very evenly Garlyn Grind Pro coped with all the tasks assigned to it.

Practice tests

Standard testing

We tested it by grinding chilled boneless pork ham, free of membranes and fat. Our technique involved measuring the amount of meat that a Garlyn Grind Pro meat grinder could process in one minute. With three perforated grids, processing was carried out at medium speed. Since the Garlyn Grind Pro meat grinder has two grates — with a large and medium hole diameter, we conducted the test on the middle grate.

The pork butt was so clean that we didn't need to remove anything extra. We simply cut the meat into pieces that fit freely through the feed opening.

The meat grinder was running at speed six. In one minute of work we got 1.2 kg of minced pork. We rate its quality as good: the pork was chopped evenly. The operation of the device was stable, the power fluctuated slightly between 170-190 W, reaching a maximum of 218 W.

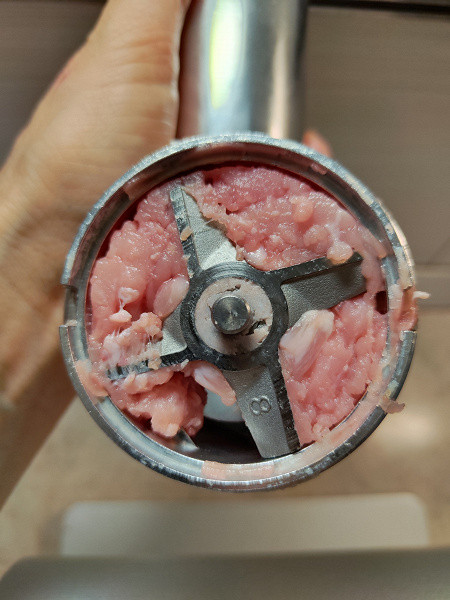

At the end of the test, we disassembled the attachment and looked at the screw and knife: the blades were clean, and around the screw shaft you could see a small amount of veins and fibers of meat.

There is a certain amount of raw material left inside the meat grinder:

The performance coefficient for Garlyn Grind Pro was found to be 1.2 kg/min.

We rate the results of standard testing both in terms of productivity and quality of grinding highly.

Ground beef

Now let's move on to our favorite stress test. All manufacturers of meat grinders recommend removing veins and veins from meat before processing, but this is not the case with the authors! To test the Garlyn Grind Pro, we purchased beef trimmings, which consisted mostly of veins of varying thicknesses and fat. Beautiful!

The test was carried out using a grid with large hole diameters. Our expectations were completely refuted when the machine, without any stress, continued to work with its smooth, quiet hum, without change, and turned the raw material into perfectly cut small pieces!

Within 2 minutes 15 seconds at speed 5, the meat grinder processed 1.78 kg of beef trimmings. We took our time, giving priority to the quality of grinding of “difficult” meats. The test results showed that the device coped with the task perfectly: the minced meat was uniform, the grate did not clog, and there were no power surges or overheating of the motor.

When disassembling the attachment, we were also pleasantly surprised: the knife blades remained clean, all the veins were cut, and only a small amount was wrapped around the auger shaft.

There is very little uncut raw material left in the body:

Result: excellent.

Minced chicken thigh fillet and preparation immediately

We decided to test the meat grinder using thigh fillet, which has fat, veins and a loose structure. This is not the easiest raw material to process, and a poor meat grinder often cannot cope with this type of meat. Veins and fat can wrap around the auger and blades, and the meat itself can get stuck in crevices, leading to unsatisfactory results. However, given the results of previous tests, we expect everything to go well this time.

The Garlyn Grind Pro meat grinder demonstrated its reliability and efficiency: the minced meat turned out uniform and perfect. We processed 1.1 kg of chicken thigh fillet without any comments on the operation of the device.

The results of the disassembly were also pleasing: no veins twisted in abundance and a large amount of stuck raw materials.

Add the minced chicken to the pork, add salt and pepper, add dried garlic and mix thoroughly.

After we put the minced meat in the refrigerator to mature, we began preparing the filling for future meals. In a frying pan with a small amount of vegetable oil, fry finely chopped onions until golden brown, then add champignons and a piece of butter for flavor. While the filling was cooling, we decided to test the operation of the grater.

Semi-hard cheese was cut into pieces that freely passed through the loading hole of the grater attachment.

At the third speed, the grater demonstrated its ideal efficiency: pieces of cheese were grated neatly, without scattering, and accumulated in a small bowl. The photo shows that there are only a few pieces left around the bowl. We grated about 150 grams of cheese with ease and speed, using almost no effort.

There was not much “waste” — in fact, just one slice wound around the drum.

Next we moved on to using a burger press. First, we wet our hands with cold water, then we formed a lump of minced meat and placed it in a large cylinder, having previously laid the bottom. Pressing the meat slightly with our fingers, we used a press to create an even indentation. Fried mushrooms were added to this cavity and cheese was sprinkled on top. Then we took a small piece of minced meat, formed it into a flat cake and placed it on top. Pressed again using a large diameter lid. The process was quick and easy, and its description turned out to be more complicated than the procedure itself for preparing zrazy using a burger press.

From the leftover minced meat we made these round cutlets.

The size of the zraz, of course, was impressive, but one piece is enough to satisfy a person with an average appetite.

They all turned out identical, smooth — a complete aesthetic pleasure for a perfectionist.

In cross-section, the zrazy also looked quite tolerable.

So, during the experiment, we ground fatty, loose meat, grated cheese, and enjoyed working with the burger press. The meat grinder and its accessories handled all operations and tasks perfectly.

Result: excellent.

Slicing and chopping vegetables

Of the three standard attachments — for slicing, shredding and fine grating, the most popular, according to our observations, was the grater. In the previous test we used it to grate a relatively soft product, and now let's check how it copes with hard vegetables.

We grated carrots and Chinese radish (daikon). Within a minute and a half of running the vegetable cutter at third speed, both root vegetables were ready for the salad. The process went quickly, the slices turned out smooth and approximately the same size.

Scattering is negligible. The waste again turned out to be a piece of raw material that fell between the internal cavity of the nozzle and the sharpened edges of the holes.

All that remains is to add salt and mayonnaise to get a bowl of simple but delicious salad.

Result: excellent.

Juice extraction

The instructions indicate that the juicer attachment is not intended for extracting juice from hard vegetables, but we could not ignore this (we are stress testing!), especially since the display indicated that the first speed is suitable for extracting juice from carrots. We should have tried the carrot juice!

We took three apples and one carrot. The apples weighed exactly 600 g, and the carrots — 190 g.

The instructions indicate that the juicer attachment is not intended for extracting juice from hard vegetables, but we could not ignore this (we are stress testing!), especially since the display indicated that the first speed is suitable for extracting juice from carrots. We should have tried the carrot juice!

We took three apples and one carrot. The apples weighed exactly 600 g, and the carrots — 190 g.

This is what the cake looked like: compressed and well-wrung out apple peel.

It was interesting to look at the contents of the case. Inside there was a homogeneous puree (edible, by the way) and pulp on the auger closer to its narrow part.

The test did not work out with carrots. The auger creaked, but swallowed small pieces of root crops, but when the first drops of juice appeared, a crash was heard and the front fixing part flew off. We collected the pulp scattered on the table, disassembled the nozzle, washed it, tried to squeeze the juice again, but with the same result. Therefore, it was decided to trust what was written and leave the device alone.

We managed to squeeze juice out of apples, but how will a juicer behave with juicy oranges? Two oranges were peeled and broken into slices. Looking ahead, let us warn you that the seeds still needed to be removed.

Having started the spin cycle at second speed, we were faced with the fact that in the middle of the process the fixing ring came off again. Having carefully examined the cake, we discovered seeds. Probably, the failure of the part is caused by the inclusion of more rigid fragments in the homogeneous cake. After cleaning the parts, we reassembled the attachment and squeezed out the juice, removing the seeds from the oranges.

The juice was of excellent quality, with pulp, a clean taste and a pleasant aroma. The juice yield was 260 g from 348 g of purified raw material, which is almost 75%.

There is little cake, it is a well-pressed compressed mass.

Considering that extracting juice is still an additional, and not the main function of the device, we will rate its implementation at “4”.

Result: good.

Making sausages

At the final stage, we decided to experiment with another accessory — an attachment for making sausages.

For this test, we took a thorough approach: we purchased beef neck and pork ham. We chopped the meat at speed six through a grate with large hole diameters.

In 1 minute 45 seconds, the meat grinder successfully twisted 2.8 kg of raw materials, showing a maximum power of 175 W. Once again we were convinced of the excellent capabilities of the Garlyn Grind Pro: it was a real pleasure to watch the device work with quality meat. There was not the slightest delay or change in the sound of the motor — quietly, calmly and evenly, evenly sliced pork and beef came out of the grates.

We didn't have nitrite salt, so we added regular table salt and a decent amount of freshly ground black pepper. Having thoroughly mixed the minced meat, we sent it for half a day to mature.

For stuffing, we used a large-diameter nozzle, since we had regular pork intestines. Having started the meat grinder at first speed, we calmly got down to business.

In total, stuffing took about 40 minutes. Most of this time the meat grinder was working, the pauses were occupied by stretching the casing and tying knots.

The ability to regulate the speed always has a very positive effect on the process of stuffing sausages. And let us once again marvel at the ease with which the Garlyn Grind Pro shreds meat.

Result: excellent.

conclusions

The Garlyn Grind Pro meat grinder made the best impression on us. The device is made of high quality, equipped with many useful and interesting accessories and attachments that significantly expand its functionality. It is easy to use and keep clean. The electronic controls are intuitive and the buttons operate consistently and predictably. There are some doubts about the automatic locking of the attachments, but the manufacturer claims that in addition to convenience and quick assembly, this function ensures reliability and the absence of backlash and vibration during operation. During all testing, no problems were found with the automatic attachment of attachments.

I would like to highlight the excellent results of our tests: the meat grinder easily coped with chopping a wide variety of meat, quickly turning it into high-quality minced meat. In minimal time, she processed almost three kilograms of beef and pork. I was particularly impressed with the accessories, such as the burger press and sausage attachments. I would also like to note the demand for additional attachments, such as a juicer and vegetable cutter, which also demonstrated high quality work. In addition, it is worth mentioning the convenience of the container for storing parts and the use of a standard network cable, which is an additional advantage of the device.

Pros:

- multifunctionality

- a large number of accessories and attachments and a container for storing them

- ease of operation, management and maintenance

- six operating speeds

- copes with grinding any meat, including stringy beef

- standard power cord

Minuses:

- need to be careful when handling parts (sharp blades)