We have previously written about Zubr brand equipment, but, oddly enough, we have not yet studied the screwdrivers of this brand. To fill this gap, let's look at one of the most popular models, which is distinguished by its compactness and, as stated, high efficiency.

Characteristics

The main characteristics of the tool are presented in the table. This and other information can be found on the product page .

| Manufacturer | Bison |

|---|---|

| Model (article) | DSL-125-22 |

| Device type | hand-held cordless drill-driver with removable battery |

| engine's type | brush |

| Chuck type, diameter | quick-release with lock, 0.8-10 mm |

| Reverse mechanism | There is |

| Impact function | No |

| Speed | 2 ranges:

|

| Torque |

|

| Built-in backlight | LED, top type |

| Dimensions W×H×D, weight (with battery) | 56×185×190 mm with battery, 1030 g |

| Battery | |

| Type | Removable lithium-ion |

| Voltage | 12 V |

| Capacity | 2000 mAh (24 Wh) |

| Charging time | 60 minutes |

| Efficiency, operating time (measured) |

|

Equipment

The screwdriver is supplied in a plastic case, which has special recesses for storing the tool itself, batteries, charger and bits.

The screwdriver comes with a charger with two batteries, paper products and one “test” double-sided bit.

At first sight

Most compact pistol-type screwdrivers have an advantage over standard full-size models due to their short working length or horizontal dimensions. The shorter the clutch extension, the more convenient it is to work in a confined space. We have seen screwdrivers with a depth of only 140 mm, which is an absolute record among all the tools we have studied, including impact wrenches (which usually have a short working part). The hero of our review today is not a record holder — the length of its working part is 190 mm. This is probably due to the use of a brushed motor, which usually takes up more space compared to a brushless one.

Otherwise, the design and construction are no different from standard conventional screwdrivers.

The screwdriver handle has numerous rubber inserts, thanks to which the tool is held securely and comfortably in the hand.

The built-in backlight is located at the top, it is used in most screwdrivers, and in screwdrivers with a pistol-type battery — always.

The full stroke of the trigger lever is 8 mm. When the lever is pressed by 1.5 mm, the backlight turns on and the battery charge indicators light up. When the lever is pressed further by half a millimeter, the engine starts. Thus, only 6 mm remains for adjusting the rotation speed, which is not much.

It's a pity that the backlight immediately turns off when you release the lever. Sometimes it can be useful to use the tool as a flashlight. Some manufacturers understand this and make sure that the backlight stays on for about 10 seconds, which is enough to point the bit at another target. Unfortunately, this is not our case.

It seems that the developers of this tool may not have paid due attention to detail. Otherwise, how can you explain the lack of fasteners in a compact (as it is supposed to be) tool? No bracket, no simple cord. How is the screwdriver supposed to be carried? In your pocket? With a bit installed in the chuck? We hasten to disappoint you: a kilogram screwdriver will not fit into a standard pocket, even a work suit. And if it does fit, the suit will hang down. This is inconvenient and unsafe, given the sharp bit or drill sticking out of the chuck.

Instructions

The included manual clearly describes the screwdriver's structure and controls in large pictures. This is rare these days.

Management

The trigger is pressed with medium force and has a stroke of 9 mm. The first millimeter of stroke is idle, at the 2nd the flashlight and charge indicators are turned on, and at a depth of 3 mm the motor is turned on. Thus, 6 mm of lever stroke remains for adjusting the spindle rotation speed.

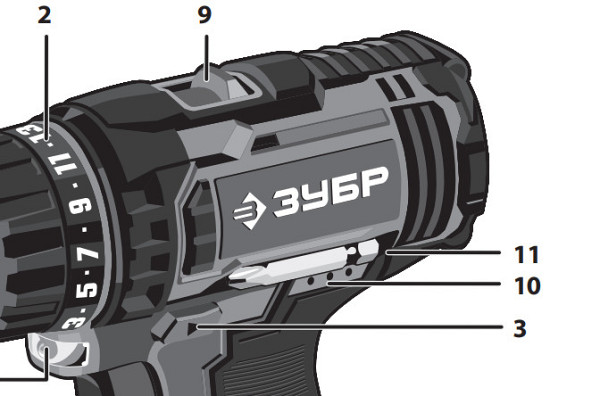

The direction of spindle rotation is selected by a standard electronic switch, which changes the polarity of the connection to the motor. The middle position of the switch locks the start lever, which is recommended for storing and carrying the tool.

The ring with numbers and divisions regulates the torque, fixing each position with a tactilely distinct and clearly audible click. The extreme division switches the screwdriver to drilling mode, disabling the «ratchet».

The speed ranges are switched by a switch located on top, as with all screwdrivers. However, the numbers on the red slider are almost indistinguishable, even in good lighting. The manufacturer once again regretted a drop of white paint.

In the first speed range, the spindle rotates up to 350 rpm at idle, and switching to the 2nd range increases the speed to 1300 rpm. Not too fast, mind you. These figures are taken from the documentation. But recently we armed ourselves with a simple but effective device. Let's check whether the speeds declared by the manufacturer correspond to the actual values. First, switch the screwdriver to the first speed, then to the second range and press the trigger all the way down.

Verdict: almost compliant. The battery was fully charged and the chuck was not loaded, but the actual chuck rotation speed was 10-15% lower than the nominal one. This is, of course, not good. This speed is sufficient for screwing in screws, but the tool is also positioned as a drill. And when drilling, not only low but also high speed is sometimes required.

Good news: the screwdriver is equipped with an automatic spindle lock mechanism when the engine is off. This is very convenient for changing accessories with one hand. Without such a mechanism, you would have to use both hands to secure and release the bit or drill: one to hold the ring and the other to screw in the chuck. Fortunately, new models of screwdrivers, even inexpensive ones, are increasingly equipped with a spindle lock mechanism when the engine is not running, which is becoming commonplace rather than an exception.

The chuck is attached to the spindle with a Phillips screw with reverse thread. To replace the chuck or service it, you will need a short Phillips screwdriver.

The battery is inserted into the handle of the screwdriver and securely fixed with side latches.

Let's not forget to mention a useful feature of the screwdriver — magnets that hold spare bits directly on the sides of the body. There are two magnets, one on each side. This method of fastening the equipment is also mentioned in the manual.

And indeed, there are round magnets, and they hold the bits quite securely.

However, after half an hour of work, without falls or impacts, we found that the magnets had sunk into the body. And this was with short-term, non-extreme use. As a result, the bit could no longer be «glued» to the body.

It looks like the magnets just weren't securely attached. Maybe using another magnet would get them back in place, but that would be a bit sloppy.

Exploitation

The screwdriver in question, like many modern models, is equipped with a protection system. The tool will automatically stop in the following cases:

- Overload: if the tool consumes abnormally high current.

- Overheating: it is necessary to allow the tool and battery to cool down before restarting.

- Long-term operation at low speed can lead to overheating of the motor.

Standard operating rules for all screwdrivers include:

- The operating mode must match the purpose. For drilling, switch to the 2nd speed and set the ratchet ring to the drill mode to avoid overheating of the motor.

- For working with screws, bolts or nuts, it is better to use the 1st speed. To avoid stripping the heads, set the torque ring to a position corresponding to the length, thickness of the fastener and the density of the material. However, working at the first speed can be very slow.

Care

The chuck, motor and battery are three key components that require regular maintenance. The chuck should be cleaned of dirt, the screwdriver should not be stored in damp or unheated rooms, and when storing it is advisable to set the reverse switch to the middle position. It is also recommended to regularly recharge the batteries.

Our measurements

Screwdriver: Torque. A Test That Worked

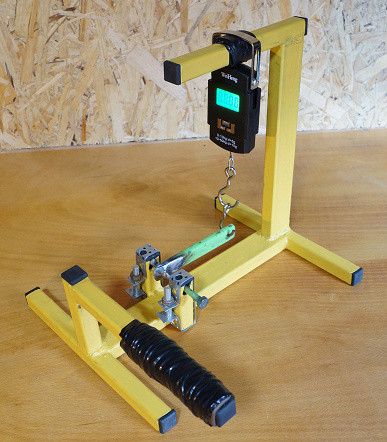

Torque is the force with which the spindle with the chuck rotates. We measure torque on a simple stand

To take measurements, the screwdriver must be in drilling mode, i.e. with the ratchet turned off. Although it is possible to overheat and burn out the motor under excessive load, modern screwdrivers are equipped with protection (Hall sensor or current consumption meter), which turns off the motor after a certain time after the shaft is locked in drilling mode. The newer the screwdriver, the faster the motor is turned off after the shaft is locked. Our screwdriver can be considered old-fashioned, since after the spindle is locked, the motor continues to run for about two seconds. This time is enough to measure the torque. Below is a freeze frame from a test video with a high frame rate.

To take measurements, the screwdriver must be in drilling mode, i.e. with the ratchet turned off. Although it is possible to overheat and burn out the motor under excessive load, modern screwdrivers are equipped with protection (Hall sensor or current consumption meter), which turns off the motor after a certain time after the shaft is locked in drilling mode. The newer the screwdriver, the faster the motor is turned off after the shaft is locked. Our screwdriver can be considered old-fashioned, since after the spindle is locked, the motor continues to run for about two seconds. This time is enough to measure the torque. Below is a freeze frame from a test video with a high frame rate.

| Model | Battery voltage, V | Cr. moment passport, N m | Measured torque, Nm | Discrepancy, times |

|---|---|---|---|---|

| Deko GCD12DU3 | 12 | 32 | 7 | 4.6 |

| Kolner KCD 12M | 12 | 14 | 7 | 2.0 |

| Zitrek Green 12 | 12 | 32 | 4 | 8.0 |

| Bosch Ixo | 3.6 | 4.5 | 3.5 | 1.3 |

| Stanley SBD201M2K | 18 | 55 | 55 | 1.0 |

| Tonfon 12V | 12 | 25 | 12.5 | 2.0 |

| Worx AiDrill WX178 | 20 | 20 | 8.3 | 2.4 |

| Black+Decker BL186K1B2 | 18 | 52 | — | — |

| Metabo PowerMaxx BS Basic | 12 | 34 | 19.5 | 1.7 |

| Metabo PowerMaxx BS BL | 12 | 38 | — | — |

| Deko DKCD20FU-Li | 20 | 42 | 5.3 | 7.9 |

| Interskol DA-10/12V | 12 | 36 | 11.5 | 3.1 |

| Bort BAB-12x2Li-FD | 12 | 36 | 6.2 | 5.8 |

| Nocord NCD-12.1.15.B | 12 | 25 | 12 | 2.1 |

| Worx WX354 | 20 | 60 | — | — |

| Toua DBLD120 | 12 | 40 | 4.7 | 8.5 |

| Zubr DSL-125-22 | 12 | 15 | 10 | 1.5 |

So, in terms of the parameter «declared torque — measured torque» our screwdriver behaves quite modestly, not provocatively. What will the following measurements show?

Screwdriver: An unscientific test with a great result

This practical test involves screwing 50 mm long and 3.5 mm diameter screws into dry wood (pine). The purpose of the test is to determine how many screws the screwdriver can screw in on one battery charge. The battery is fully charged before starting work.

During the test, the screwdriver in question worked from a fully charged battery for about 40 minutes and screwed in 293 screws. Such good autonomy from a compact screwdriver with a pistol battery was unexpected.

The following table shows the battery capacity of the tested screwdrivers in watt-hours and the number of screws screwed in pieces. From this data, the amount of energy expended by the screwdriver to screw in one screw is calculated. This is the efficiency. The higher its value, the more efficient the screwdriver.

| Model | Battery voltage, V | Battery capacity, Wh (V Ah) | Self-tapping screws screwed in, pcs. | Efficiency (higher = better) |

|---|---|---|---|---|

| Deko GCD12DU3 | 12 | 18 | 210 | 11.7 |

| Kolner KCD 12M | 12 | 12 | 28 | 2,3 |

| Zitrek Green 12 | 12 | 18 | 222 | 12.3 |

| Bosch Ixo | 3.6 | 5.4 | 0 | 0,0 |

| Stanley SBD201M2K | 18 | 72 | 1293 | 18.0 |

| Tonfon 12V | 12 | 24 | 376 | 15.7 |

| Worx AiDrill WX178 | 20 | 40 | 750 | 18.8 |

| Black+Decker BL186K1B2 | 18 | 36 | 717 | 19.9 |

| Metabo PowerMaxx BS Basic | 12 | 24 | 413 | 17.2 |

| Metabo PowerMaxx BS BL | 12 | 24 | 387 | 16.1 |

| Deko DKCD20FU-Li | 20 | 40 | 525 | 13.1 |

| Interskol DA-10/12V | 12 | 18 | 286 | 15.8 |

| Bort BAB-12x2Li-FD | 12 | 18 | 176 | 9.7 |

| Nocord NCD-12.1.15.B | 12 | 18 | 266 | 14.7 |

| Worx WX354 | 20 | 40 | 705 | 17.6 |

| Toua DBLD120 | 12 | 24 | 401 | 16.7 |

| Zubr DSL-125-22 | 12 | 24 | 293 | 12.2 |

The obtained coefficient of 12.2 indicates an average efficiency, typical for tools in the middle and lower price range.

The screwdriver allows you to adjust the force in the range from 1 to 30 conventional divisions of the adjusting clutch. When screwing 50-millimeter screws into dry wood, we mainly used the maximum force, switching the «ratchet» to the end of the scale. Despite the declared good torque, the screwdriver begins to noticeably «strain» already at half the screw, which indicates a loss of torque with significant resistance. Perhaps this is due to the brush motor?

The screwdriver copes well with thin and short screws, but for thick and long screws, pre-drilling of holes is required.

Screwdriver: battery

The screwdriver is supplied with two batteries with a capacity of 2000 mAh and a voltage of 12 V (24 Wh). There are no indicators of the remaining charge on the batteries.

The included charger is a compact station that operates on 100-240 V and has a 12 V/2.4 A output. During charging, the LED indicator on the station shows the current operating mode or signals faults such as battery failure or overheating. Once charging is complete, the indicator glows green continuously.

Charging an empty battery takes a relatively short time, 60 minutes. This allows for almost continuous operation: one battery powers the screwdriver, and the second is charged.

conclusions

The Zubr DSL-125-22 screwdriver has good autonomy, is compact, has a chuck with a spindle lock, and two complete batteries with a charger allow almost continuous operation.

Pros:

- spindle with a lock when the engine is not running

- good autonomy

- complete plastic case for storage

Cons:

- sloppy manufacturing

- reduction in torque with resistance

- lack of a fastening bracket or strap