Passport specifications, delivery set and price

| Manufacturer | Arctic |

|---|---|

| Model | Arctic Liquid Freezer III 420 A-RGB White |

| Model code | ACFRE00145A, EAN: 4895213704533 |

| Cooling system type | liquid closed type prefilled non-expandable for processor |

| Compatibility | motherboards with processor sockets Intel: LGA1851, LGA1700; AMD: AM5, AM4 |

| Cooling capacity | PI: 374 W, NNPI: 339 W |

| Fan type | axial (axial), 3 pcs., model P14 PWM PST A-RGB |

| Power supply for fans | Motor: 12V, 0.17A, 4-pin connector (common, power, rotation sensor, PWM control) Backlight: 5V, 0.4A, 3-pin connector (common, data, power), 12 A-RGB LEDs |

| Fan sizes | 140×140×27 mm |

| Fan speed | 200 — 1900 rpm |

| Fan performance | 117.06 m³/h (69.90 ft³/min) |

| Fan static pressure | 19.6 Pa (2.0 mm water column) |

| Fan noise level | 0.3 son |

| Fan bearing | hydrodynamic (Fluid Dynamic Bearing) |

| Radiator dimensions | 458×138×38 mm |

| Radiator material | aluminum |

| water pump | integrated with heat sink, equipped with removable fan for VRM cooling |

| Pump rotation speed | 800—2800 rpm |

| Pump power supply | Motor: 12V, 0.35A, PWM control |

| VRM Cooling Fan | Motor: 400-2500 rpm, 12 V, 0.05 A, PWM control; Backlight: 5 V, 0.4 A, 12 A-RGB LEDs |

| Pump dimensions (W×D×H) | 108.5×91×68.5 mm |

| Heat sink material | copper |

| Thermal interface of heat sink | Arctic MX-6 thermal paste in a syringe |

| Hoses | rubber in a braid, length 450 mm, outer diameter 12.4 mm, inner 6 mm |

| Mass of the system | 2325 g |

| Connecting the system | Fan and Pump Motors: to 4-pin fan/pump header on motherboard (Common, Power, RPM Sensor, PWM Control) or to three 4-pin fan/pump headers on motherboard; Lighting: to 3-pin header (Addressable LED Lighting — Common, Data, 5V Power) on motherboard or third-party controller. |

| Peculiarities |

|

| Contents of delivery |

|

| Estimated cost | €97.5 on the manufacturer's website |

Description

The manufacturer offers various models of liquid cooling systems of the Liquid Freezer III series, which differ in the size of the radiators (240, 360, 280 and 420 mm), the presence or absence of backlighting, as well as the color of the case. For testing, we had a white model with a 420 mm radiator and decorative backlighting on the fans and pump. One of the key features of this series is the declared compatibility with Intel processors installed in the LGA1851 socket.

The Arctic Liquid Freezer III 420 A-RGB White liquid cooling system is supplied in a medium-thick corrugated cardboard package.

Inside the box we found everything listed in the table above:

There is no printed manual and it cannot be downloaded directly from the site; instead, you need to click on the link in the QR code and read the interactive manual on the company's website. This is not very convenient. The site also provides a description of the system and a PDF file with the specifications.

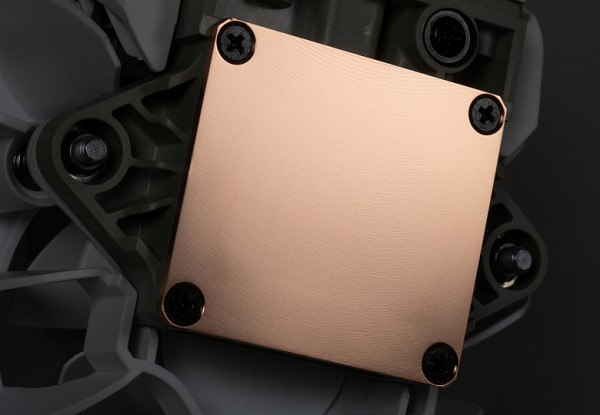

The system is sealed, filled and ready to use. The pump is combined with the heat sink in one unit. A copper plate serves as the base of the heat sink, which is adjacent to the processor cover. The outer surface of the plate is ground and lightly polished, with a small convex center, the difference in which is about 0.1 mm.

The copper plate measures 44×40 mm, while the inner part, limited by holes, is 33×29 mm.

The thermal paste comes in a small syringe, which is less convenient than a pre-applied layer. The thermal paste supply is enough for exactly one application, and in the best case, for two, if the processor has a small cover area and the consumption is economical. High-quality thermal paste from another manufacturer was used in all tests.

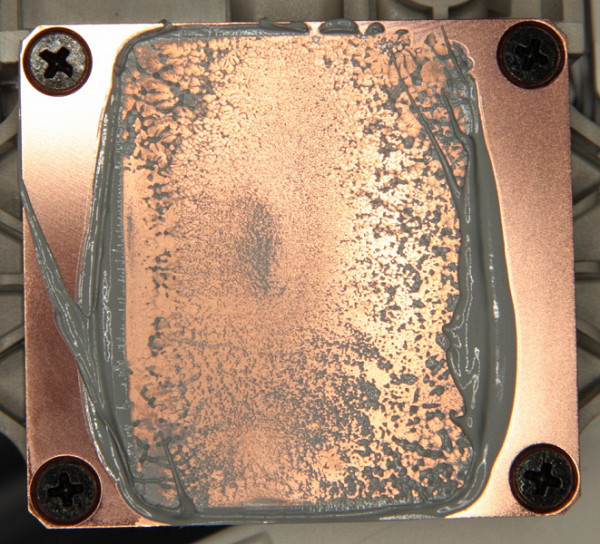

Before the test results, we will show how the thermal paste was distributed after completing all tests on the Intel Core i9-13900K processor:

And on the sole of the pump:

The thermal paste was spread in a thin layer over almost the entire surface of the processor cover, and its excess was squeezed out over the edges. The area of tight contact is located approximately in the center and occupies a significant area. (The distribution of the thermal paste may have changed slightly when the processor and pump were separated.)

The peculiarity of this liquid cooling system is the use of a special processor clamping frame, which replaces the standard one. This frame helps prevent deformation of the printed circuit board and the processor itself, reducing the risk of damage over time. The pump is attached with two screws into the threaded holes through a spring plate with a central clamp, which simplifies installation and virtually eliminates the skew of the heat sink relative to the processor cover.

The pump body is made of durable white plastic.

The removable top of the pump contains decorative lighting and a built-in fan designed to cool the voltage regulator module (VRM).

There is an opinion that using a liquid cooling system with conventional water blocks can reduce the stability of the system due to VRM overheating, since, unlike air coolers, these components are cooled worse when installing a liquid cooling system. We have repeatedly seen that the temperature of the VRM radiators decreases when such a fan is running. Of course, an additional fan increases the noise level and reduces the overall reliability of the system, but in extreme cases, with separate control, its rotation speed can be reduced to a minimum.

Another feature of this liquid cooling system is the connection of the pump motors, all fans and lighting using cables coming from the pump. The cables for connecting the fans on the radiator come from the pump and are neatly laid under the braid of one of the hoses, which makes connecting the system convenient and neat. The backlight connection cable (42 cm long) is non-removable, while the removable cable (about 40 cm long) for connecting the motors is available in two versions: with one 4-pin connector (common, power, rotation sensor, PWM control) and with three four-pin pads, two of which have only two contacts installed. The first cable allows you to supply power and a PWM control signal to all motors and track the rotation speed of only one fan on the radiator. The second cable allows you to supply common power and three PWM signals separately: one to all fans, one to the pump and one to the fan on the pump, as well as track the rotation speed of the fan on the radiator, pump and fan on the pump. This option allows you to implement a variety of operating scenarios for the liquid cooling system and better control its operation. The disadvantage is that power is supplied to all motors from one 4-pin connector, which can cause the connector to overheat due to the high maximum current and, over time, lead to deterioration in the quality of the contact. The hoses are elastic and flexible, they are covered with a braid of slippery plastic. The length of the hoses along the flexible part without taking into account the sleeves is 41.5 cm (long). The L-shaped fittings at the inlet to the pump are rotatable, which facilitates the installation of the system.

The radiator is made of aluminum and covered with a white matte coating on the outside, which is relatively durable.

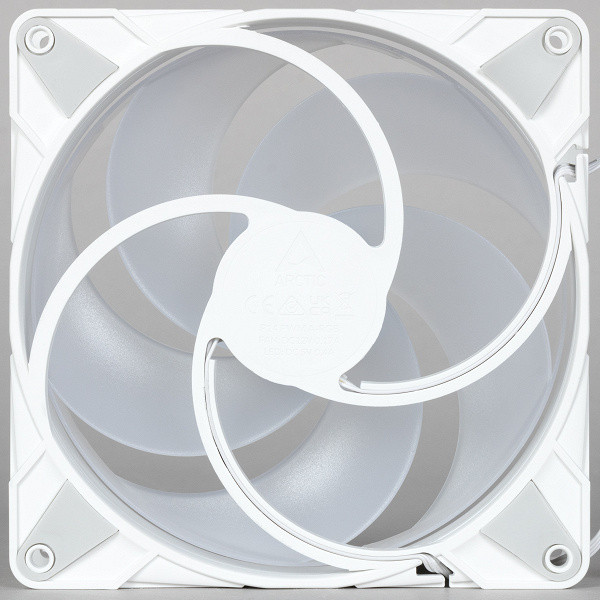

The fan frame is made of durable white plastic. Rubber vibration-insulating pads are installed on the corners of the fan frames. However, given the weight of the fan and the rigidity of these pads, it can be assumed that due to the high resonant frequency, the system will not have significant anti-vibration properties.

The shape of the fan impeller indicates its ability to create high static pressure, which is necessary in this case. The impeller blades are surrounded by a ring, which can improve the efficiency of the fan. The impeller is made of white translucent plastic. ARGB LEDs are located along the circumference of the fan stator, which illuminate the impeller from the inside. The fan cables are equipped with standard four- and three-pin connectors for connecting motors and addressable lighting; the latter also has a pass-through connector for serial connection.

The operation of the pump and fan backlight (default mode when connected to a third-party controller) is shown in the video below:

The complete system with fasteners (without the processor frame) for LGA 1700 weighs 2317 g. The fasteners are made mainly of hardened steel and have a durable galvanic or paint coating.

Testing

Determining the dependence of the cooler fan speed on the PWM duty cycle and/or supply voltage

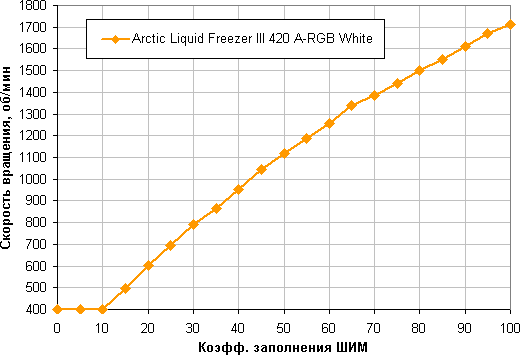

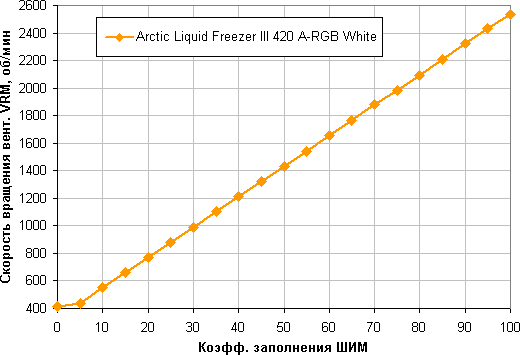

An excellent result is a monotonous and almost linear increase in rotation speed when changing the fill factor from 10% to 100%, with a wide range of speed adjustment. When the fill factor (FF) decreases to 0%, the fans do not stop. This is important if the user wants to create a hybrid cooling system that operates completely or partially in passive mode at low load.

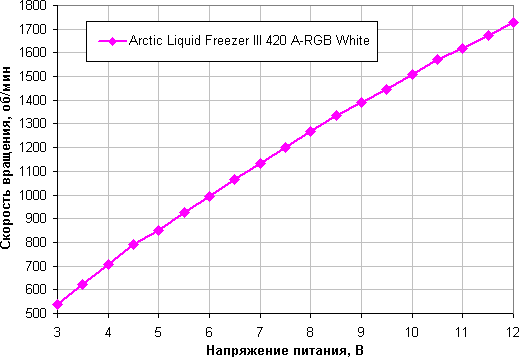

Speed control by changing the voltage provides stable rotation in a slightly smaller range. The fans stop when the voltage drops to 2.8 V and start working at a voltage of 3.5 to 3.9 V. The fans can be connected to a source with a voltage of 5 V.

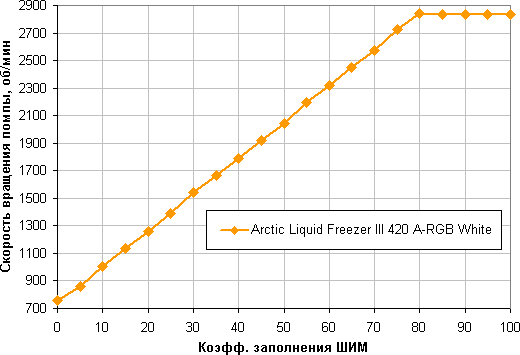

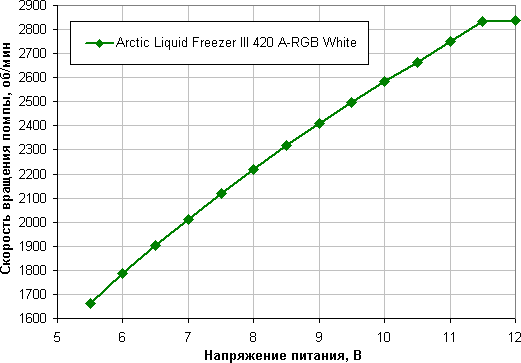

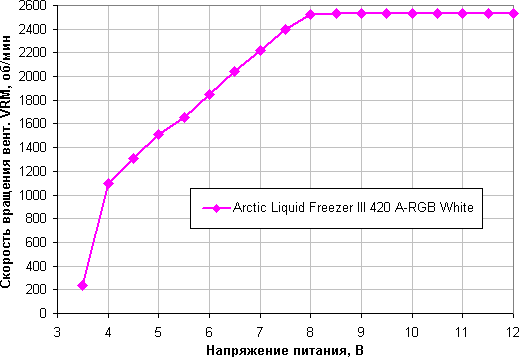

The rotation speed of the pump and the fan on the pump can also be controlled using both PWM and by changing the supply voltage. Here are the corresponding graphs.

When the duty cycle (DC) drops to 0%, the pump does not stop. The pump stops at 5.1 V and starts at 5.2 V. It is better not to connect the pump to 5 V.

When the duty cycle (DC) drops to 0%, the pump fan does not stop. The fan stops at 3.8 V and starts at 7.8 V.

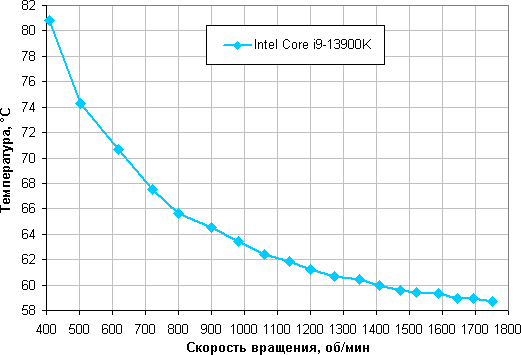

Determining the dependence of the processor temperature at full load on the rotation speed of the cooler fans

In this test, all cores of the Intel Core i9-13900K processor were running at 4.1 GHz. The pump, its fan, and the fans on the radiator were controlled using PWM.

In this test, the Intel Core i9-13900K processor does not overheat (at 24 degrees ambient air) at fan speeds achieved with a fill factor of 10% (and below), which corresponds to about 400 rpm. The maximum consumption according to monitoring data was about 218 watts, and according to the processor power connectors — 274 watts. For comparison, the base power of the processor is 125 watts, and the standard maximum short-term turbo limit is 253 watts.

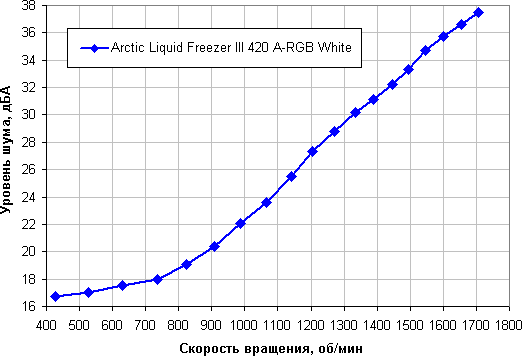

Determining the noise level depending on the rotation speed of the cooler fans

The noise level of this cooling system varies widely, but the maximum values are not very high. The noise can reach 40 dBA and higher, which is considered quite high for a desktop system; from 35 to 40 dBA is already a tolerable level; below 35 dBA, the noise from the cooling system will not be noticeable against the background of ordinary non-noisy PC components, such as case fans, fans on the power supply, video card and hard drives. The noise level below 25 dBA can be considered relatively silent. The background noise level was 16.3 dBA, according to measurements of the sound meter.

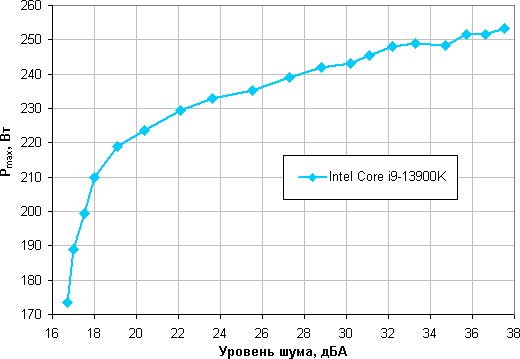

Plotting the dependence of the actual maximum power on the noise level

Let's try to consider more realistic scenarios that differ from the test bench conditions (24 degrees of ambient air). Let's assume that the temperature of the air entering the cooling system fans can reach 44 °C (for example, if the liquid cooling system is set to blow out of the case with a powerful video card). At the same time, the processor temperature under maximum load does not want to increase above 80 °C. Based on these conditions, we will build a dependence of the real maximum power (designated as Pmax, previously used the designation Max. TDP) consumed by the processor on the noise level.

Taking 25 dBA as the criterion for conditional silence, the maximum power of processors corresponding to this level is approximately 235 W for the Intel Core i9-13900K processor. If you do not take into account the noise level, the power limits can be increased to approximately 250 W. These values are based on strict conditions, when the radiator is blown with air at a temperature of 44 ° C. With a decrease in air temperature and / or an increase in the maximum permissible processor temperature (up to 100 ° C), the specified power limits for silent operation and maximum power may increase.

conclusions

To properly understand the test results, it is important to consider the following:

The purpose of testing is to determine the cooling capacity of the liquid cooling system (LCS). The processors used in the tests serve only as a heating element to evaluate the thermal resistance of the cooler in various modes. The processor power is regulated depending on the capabilities of the cooling system and can be both lower and higher than the standard values. The main goal is to avoid overheating of the processor across the entire range of the cooler's cooling capacity and to noticeably distinguish changes in the processor temperature.

Using the Arctic Liquid Freezer III 420 A-RGB White liquid cooling system, you can create a relatively silent computer (noise level of 25 dBA and below) with an Intel Core i9-13900K processor, provided that the consumption of such or a similar processor under maximum load does not exceed 235 W, and the temperature inside the case does not rise above 44 ° C, while limiting the maximum processor temperature to 80 ° C. With a decrease in the cooling air temperature, an increase in the permissible processor temperature (up to 100 ° C) or less stringent noise level requirements, the power limits can be increased. In practice, if the Intel Core i9-13900K is not overclocked or the power limits are not increased, this liquid cooling system will provide silent cooling in any real load scenarios, including moderate overclocking. The backlight on the pump and fans will decorate the interior of the system unit. Also noted is the good quality of workmanship, hose braiding, a fan on the pump for cooling VRM, neat organization of electrical connections and an original fastening system for Intel processors.