The Garlyn J-300 juicer is designed for carefully squeezing juices from various vegetables, fruits and berries. According to the manufacturer, the device effectively processes even hard and fibrous products and can work without a break for up to 25 minutes.

We've put together a series of standardized practical tests to verify whether the claimed specifications match reality, determine the true speed and efficiency of the device, and share the results of its work.

Characteristics

| Manufacturer | Garlyn |

|---|---|

| Model | J-300 |

| Type | vertical auger juicer |

| Country of origin | China |

| Guarantee | 1 year +12 months additionally when participating in the extended warranty program |

| Service life * | 3 years |

| Nominal power | 200 W |

| Maximum power | 1000 W |

| Body color | black, orange |

| Main nozzle material | plastic |

| Auger material | ultra-strong plastic, metal |

| Filter material | stainless steel |

| Control | mechanical |

| Auger rotation speed | up to 60 rpm |

| Operating modes | one speed mode and reverse |

| Protection | from improper assembly and overheating |

| Additional accessories | cleaning brush |

| Diameter of loading neck | 78 mm |

| Thrower hole diameter | 3.5×4 cm |

| Juice/pulp container capacity | 0.8/0.6 l |

| Weight | 2.4 kg |

| Dimensions (W×H×D) | 140×435×150 mm |

| Length of network cable | 1 m |

* Contrary to popular belief, this is not a period after which the device will necessarily break down. However, after this period, the manufacturer ceases to bear any responsibility for its functionality and has the right to refuse to repair it, even for a fee.

Equipment

The Garlyn J-300 juicer came to us in two packages. The outer box is made of regular brown cardboard and is decorated with a schematic image of the device, the company logo, the full name of the model and a brief description of the characteristics. Inside it was a more familiar «ceremonial» package.

On the side edges of the bright box with a branded black and orange design there are large images of the juicer, the model name, the company logo, pictograms illustrating the main advantages, as well as detailed technical specifications and information about the manufacturer. Although there are no handles on the packaging, instead there is an elegant branded ribbon with a bow.

Inside, the juicer, its components and accessories are neatly packed in separate plastic bags and securely fixed with foam inserts.

The Garlyn J-300 kit includes:

- main body with a motor unit

- a tank for separating juice and pulp

- a module with a loading neck

- auger

- pusher

- bowls for pulp and juice

- a brush for cleaning the filter

- an operating manual, a brief instruction and a warranty card

At first glance

The Garlyn J-300 juicer stands out with its original color scheme: the lower part of the body, where the motor unit is located, is made of matte plastic of a soft muted orange shade. The upper half is made of glossy translucent black plastic. In combination, they create a very attractive appearance.

On the front side of the engine block, at the bottom, there is a shiny panel with the company logo, and on the right there is a lever covered with silver plastic under the metal — this is the only control element.

The design of the Garlyn J-300 corresponds to the traditional design of vertical auger juicers: a tank is installed on the motor block, in which the juice and pulp are separated during squeezing. The height of the entire structure is 43.5 cm, and the dimensions of the base are 14 × 11.5 cm.

The waste outlet on the side of the bowl is closed with a rubber tongue, which allows you to regulate the flow of pulp. For hard products, it is recommended to completely close the hole, and for softer products, leave a small gap.

On the right side of the tank is a juice spout, which is equipped with a removable anti-drip cap with a silicone gasket to prevent leakage.

In the center of the tank is a massive auger covered with plastic. The hole for its installation is sealed with a removable silicone insert.

A fixing structure is installed on the auger — a loading tray with a movable cover (limiter) on top and a non-removable filter-grater in the lower part.

The structure is securely fixed to the motor block thanks to special projections around the circumference, which ensure a tight fit and snap. On the edge of the bowl there are drawings-hints indicating the direction of the lock.

The neck diameter is almost 9 cm, but the opening in the lid is much smaller — 3.5 x 4 cm. The non-removable limiter can be turned 180°, which allows you to place products with a diameter of up to 7 cm in the spin basket.

The plastic pusher is long enough to push the food, but is designed to not touch the rotating auger during operation.

On the bottom of the device there are four suction cup feet, a technical information plate and ventilation holes. A one-meter long power cord comes out from the back of the motor unit.

The juice and pulp containers are made of darkened plastic. The juice bowl with a convenient spout holds 800 ml. The pulp container, according to the documentation and our measurements, holds up to 600 ml, although there are no marks on it. One side of the container is concave, which allows it to fit tightly to the body. The pulp container can be placed inside the juice bowl, which is convenient for storage and saves space.

To clean the filter-grater, the kit includes a small brush with fairly hard bristles.

The assembly of Garlyn J-300 is very neat, we did not find any defects during visual inspection. The materials of the body and all components of the juicer look high-quality.

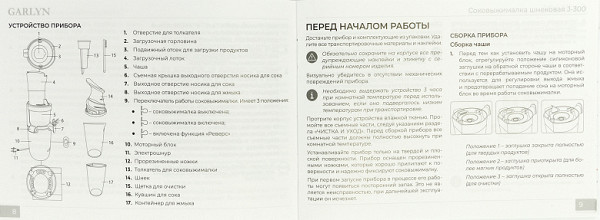

Instructions

The brochures included with the device are designed in a single corporate style and printed on high-quality glossy paper.

The main instruction is presented in the form of a 27-page manual, which contains all the necessary information about the device. It includes a description of the operating principles, recommendations for safe operation and maintenance rules. The text is well structured, contains schematic drawings and is written in an easy-to-understand language.

The brief instruction is designed as an A5 format memo, containing the most important information from the main document. The warranty card is presented as a separate booklet.

Control

Garlyn J-300 is controlled by a mechanical three-position switch located on the side of the motor unit housing. The device has one speed.

The switch has three positions: down — the juicer is on, horizontal — off, up to the stop — reverse is activated. To activate the reverse mode, the switch must be held in the corresponding position, and to stop, just release it.

If the loading neck is not installed correctly on the motor block, the juicer will not turn on.

Operation

The operating instructions do not contain any special requirements for preparing the juicer before the first start. It is enough to wipe the motor unit, wash the components, dry them and assemble the structure.

Then the process is very simple: prepare the ingredients, connect the device to the network, lower the lever on the body down, and you can start adding pieces into the neck.

Since the opening in the reversible lid is quite small, hard fruits will have to be cut into pieces. At first, the lid was a little in the way, but we quickly got used to it. Halves of small apples and small tomatoes fit well, but two or three grapefruit slices will not fit.

It is not recommended to operate the juicer for more than 25 minutes at a time. The recommended duration of the break between cycles is not specified. According to our estimates, in 25 minutes you can process 16 kg of apples and get almost 9 liters of juice.

Under any load, the Garlyn J-300 works quietly and calmly. Regardless of the type of raw material, there were no jams or emergency shutdowns. The juice was always excellent quality, with the exception of apple, which sometimes had a moderate amount of foam or even no foam at all. The pulp was usually quite dry, the only exception being grapefruit.

The containers for juice and pulp are generally convenient, but in tests with apples and carrots, the capacity of the pulp container was insufficient.

Care

The motor unit can be wiped with a damp cloth. All removable parts of the structure should be washed under running water using a soft sponge and neutral detergent. It is recommended to use the included brush to clean the filter-grater.

As an alternative method, you can first pour 200 ml of water into the neck, close the juice outlet valve and run the device for a few minutes. Then drain the liquid into a container, disassemble the juicer and rinse the parts under the tap. Do not immerse the motor unit in water or wash any parts of the juicer in the dishwasher.

Our measurements

The power consumption of the juicer varies depending on the hardness of the ingredients being processed. On average, it is 86-158 W. We recorded a maximum consumption of 239 W when juicing carrots and a little less — 219 W — when processing apples.

The juicer produces moderate noise during operation, but when processing carrots, apples and cabbage, a loud creaking sound is heard, coming from the products themselves, and not from the device. The noise when juicing grapefruit is 65-68 dBA, while when processing apples, the noise level reaches 78 dBA.

Practice tests

The juicer testing methodology includes a series of mandatory tests. We squeeze exactly one kilogram of a specific raw material: Granny Smith apples, pink grapefruits, white cabbage and carrots. This allows us to determine the productivity coefficient, i.e. the average weight of juice obtained from a kilogram of product, as well as the average time spent processing this volume.

Essential Test #1 (Granny Smith Apples)

1 kg of apples were cut into quarters, the stems were removed and the core was cut out.

We turned on the juicer and started the stopwatch, actively starting to throw pieces into the neck. There were no problems: the sharp tip of the auger easily cut the falling apple slices and quickly pushed them down, so that the pusher was unnecessary.

The juice turned out to be thick and opaque, with a small amount of suspended pulp settling to the bottom of the container.

The pulp in the container was almost dry, only small remnants of pulp remained on the screw. There was enough foam, as is often the case when squeezing apples. We set a record in time: not even all centrifugal juicers can handle a kilogram of hard green apples so quickly. However, the volume of juice was less than usual for such devices.

Result: 1 minute 30 seconds, 550 grams of juice (without foam)

Mandatory Test #2 (Pink Grapefruit)

The grapefruits were peeled, broken into segments and had as much of the white film removed as possible.

There were no difficulties with processing the fruit. The slices were processed without delay, but not as quickly as in the previous test.

At the bottom of the waste container, in addition to the rather damp pulp, a small amount of juice had accumulated.

The juice is opaque, with barely visible small particles of pulp.

Result: 3 minutes 10 seconds, 770 grams of juice (without foam)

Mandatory test #3 (carrot)

We cut the carrots into 2-4 pieces and put them in one at a time, waiting until the first one went into the auger at least halfway. The root vegetables crackled, and the juicer confidently and consistently processed them into thick, dense juice.

The pulp turned out to be moderately moist, microscopic pulp was found only at the bottom of the glass. In the middle of the process, the waste container had to be emptied. Very little juice came out.

Result: 2 minutes 17 seconds, 255 grams of juice (without foam)

Mandatory test #4 (cabbage)

A large head of cabbage was cut into strips, based on the size of the loading hole in the lid.

In the process, it was necessary to constantly use a pusher, because the leaves themselves were almost not pressed. In connection with this, the juice extraction was not very fast.

In addition, small pieces were loaded one by one, which also takes time. As a result, we got a dense and rich juice with a foam cap about a centimeter high. The cake briquettes collected in the glass were moderately moist, and there were no whole pieces of cabbage among them. The volume of juice again was not very large.

Result: 6 minutes 10 seconds, 330 grams of juice (without foam)

Summing up the testing results

The average speed and efficiency of the Garlyn J-300 juicer based on the results of four mandatory tests were 3 minutes 16 seconds and 476 g, respectively.

You can see the results of all the tested juicers, and a comparison of the Garlyn J-300 with competitors shows that it ranks high in speed, while it is at the very end of the list in efficiency.

It is important to consider that the efficiency of juice extraction can be affected by many factors, among which the most important is the quality of the raw material (in addition to the characteristics of the juicer itself).

Celery, grapes and whole apples

For an additional test, we decided to make the juicer's job more difficult by taking a grape twig with seeds, several small apples, and three celery stalks. We didn't make any cuts — it would be more interesting that way.

We lowered the products one after another into the neck and in a couple of minutes we got excellent thick juice without foreign inclusions, with a moderate amount of foam and almost dry pulp.

The celery fibres remain intact, demonstrating the truly gentle cold pressing method.

From 450 g of raw material we got almost 300 g of juice without taking into account the foam.

Result: excellent

Conclusions

The Garlyn J-300 juicer attracts with its stylish design, works quite quietly, is compact and demonstrates good speed for its class. However, it is worth noting that its juice yield is slightly lower compared to similar devices. Otherwise, the device is easy to use and maintain.

The juicer has a high-quality assembly and includes containers for pulp and juice, as well as a brush for cleaning hard-to-reach places. It is perfect for daily home use and will cope with a large volume of products, although the glasses for juice and waste will have to be emptied or replaced frequently.

The non-removable reversible loader on the neck is easy to get used to, especially when processing whole small fruits. Among the advantages, we can note the protection against switching on if improperly assembled and the anti-drip valve on the juice spout.

Pros:

- nice design and compactness

- easy to assemble and maintain

- fairly high spin speed

- up to 25 minutes of continuous operation

- moderate noise

Cons:

- juice squeezing efficiency is not the highest