Continuing our fascinating introduction to DCK brand products, let's move on to one of the most popular types of tools — the angle grinder (AG), better known as a Bulgarian. Let's start with the most «modern» model, equipped with speed control and battery-powered.

Characteristics

The main characteristics of the tool are presented in the following table. This and other information can be found on the product page (note that there are no separate pages for DCK products, the entire model range is located on single pages «Network tool», «Battery tool», etc.).

| Manufacturer | DCK |

|---|---|

| Model (article) | KDSM04-125 |

| Device type | hand-held cordless angle grinder |

| Engine type | brushless |

| Disc diameter | 125 mm |

| Spindle thread | M14 |

| Max. cutting depth (disc extension) | 30 mm |

| Rotation speed | three speeds:

|

| Built-in backlight | No |

| Engine blocking when the disc is jammed | Yes |

| Soft start | No |

| Engine brake | No |

| Dimensions, weight |

|

| Battery type | lithium-ion |

| Voltage | 18 V |

| Battery life under load | about 13 minutes of metal grinding with a petal attachment (with a 5 Ah battery) |

Equipment

The tool provided for testing comes in its own luxury case with a foam molding for careful storage of the tool and accessories.

The angle grinder comes complete with a protective cover, handle, key, two batteries with a charger and printed materials.

Design, control

The angle grinder in question is powered by a brushless motor.

The design of the tool is the same as all angle grinders. It is impossible to come up with a more optimal and convenient option.

The auxiliary handle can be installed on either side of the gearbox, which is convenient for both right-handed and left-handed people. The shape of the handle, which is two «pancakes» with an accordion between them, may create the impression of having a mechanism for compensating vibrations, but in fact it is rigid along its entire length. It is important to note that the presence of a vibration damper in this case would be strange. This function makes sense only for hammer drills or chipping hammers, and it is not required in angle grinders, since one of the main conditions for working with a grinder is the accuracy of holding the tool.

The machine is controlled by a standard slide switch with a lock, which in our tool is located at the top.

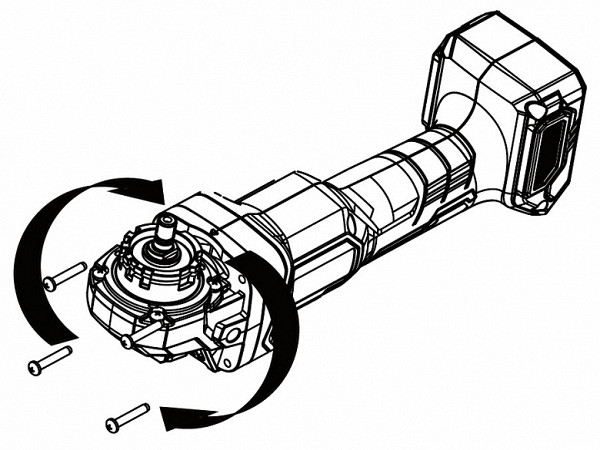

In addition, not only the handle of the tool can be installed from different sides — the entire gearbox unit can also be turned over! It is enough to unscrew four screws, and the head can be rotated 180°. As a result, the switch will move from the top to the bottom. The main thing is not to forget to put the screws back in place after this operation.

To change the position of the protective cover, no key is required. Just press the special spring-loaded red lever, and the cover easily turns in the desired direction, within certain limits, of course.

The device specifications do not specify either a smooth start or an electric motor brake. There really is no brake: when the motor is turned off, the attachment continues to rotate under the action of centrifugal force, and the heavier the attachment, the longer it will rotate. However, after turning off the motor, there is a slight delay, reminiscent of the operation of a weak ratchet, which is probably due to the features of the gearbox. This leads to the fact that the rotation of the attachment stops just a second earlier than with a conventional mains grinder, which has no brake at all. Although even a second in such situations is not bad.

The spindle rotation speed is regulated using an electronic display, where each digit is a button. The last indicator with an exclamation mark icon signals overload or overheating of the tool.

What kind of technical review would it be without checking the rotation speed? Of course, testing was carried out. It was traditionally carried out with a fully charged battery in idle mode, without load. As a result, we found minor discrepancies with the passport data, but only in the first two speed ranges. The third range showed a more serious discrepancy, although not critical:

- according to the passport: 4000/6500/9000 rpm

- measured: 3970/6442/8016 rpm

The overhang of a 125 mm disc is 30 mm, which theoretically corresponds to the maximum cutting depth. However, this parameter is rather conditional, since it changes and decreases as the disc wears during sawing.

The inner diameter of the protective casing is 143 mm, and the height of the rim is 25 mm (before the bend). These dimensions allow the use of any nozzles with the casing, including non-standard ones whose actual diameters exceed 125 mm.

Instructions

The angle grinder comes with a detailed instruction manual that outlines safety precautions and methods for performing various tasks. Although the illustrations are small, this is already a standard for most instructions and manuals.

Operation

Attaching the attachments

The grinder uses a standard spindle with M14 thread to attach the attachments. The attachment is fixed with a nut, which is screwed onto the spindle thread and tightened with the included key. However, it is worth noting that the nut has a unique design: it is compatible only with the key included in the kit. Keys from other grinders will not work, at least, there were none in our workshop, although the author has several grinders and keys for them. The fact is that the distance between the hooks of the nut and the key is 35 mm, while this value is usually 30 mm. If this is important to someone, replacing the nut with a standard one can be done almost without cost.

To test the angle grinder, attachments for different purposes were prepared — for wood, metal and concrete.

Thanks to the large protective cover, all attachments fit onto the spindle without difficulty.

There are no exceptions. As already mentioned, the dimensions of the protective casing and the height of the sides allow the use of any attachments for 125 mm angle grinders. This includes even attachments with an actual diameter exceeding 125 mm, which are designed to work without a casing.

Sawing

The task was to determine the tendency of the grinder to reduce power or switch to protective mode under high load when cutting various metals. We tested the tool on an old metal profile 5 mm thick, which is significantly thicker than modern materials.

Despite a noticeable delay, the tool coped with the task. During operation, a certain limit was felt, which is better not to go beyond: a small additional force could lead to the grinder stopping. However, in general, the power of this battery model is comparable to network analogs.

Grinding

This work differs from the previous one in that the motor can be loaded even more during grinding due to the increased contact area of the attachment with the workpiece.

For grinding wood, a petal attachment designed for working with metal was chosen instead of a regular Velcro sandpaper. This decision was made because the wooden beam may contain remains of screws that can damage the soft sandpaper. The same attachment was used for processing metal.

When working with wood, the tool demonstrated excellent results: there was no hint of a lack of power or speed. However, when grinding metal, with strong pressure on the attachment, the motor clearly reduced the speed. As a result, it was necessary to reduce the pressure to avoid overload and engine stalling. Although the power is close to mains-powered analogs, it may not be enough for confident work with metal, as well as the speed.

The following photo shows the results of our angle grinder (on the left) and a regular mains-powered angle grinder with a higher rotation speed. Obviously, in this case, the winner is the corded tool, which in the same amount of time was able to polish the old rusty surface almost to a mirror shine. However, no one claimed that the cordless model can completely replace the corded one, especially in such advanced cases as thick rusty metal.

Autonomy

This is our final test, which includes long-term grinding of surfaces. This time we decided against grinding metal, since working with wood is equally easy for both mains-powered and cordless grinders. At the same time, the actual energy consumption for grinding metal and wood is almost the same, but in the case of wood, we reduce the risk of overload. Although, of course, this does not eliminate it completely.

The battery lasted almost 13 minutes of work with a wood grinding cup.

This is a completely acceptable result, but not outstanding. Previously studied grinders with similar batteries worked for about the same amount of time — from 10 to 14 minutes. Yes, cordless grinders are still a long way from their mains-powered counterparts. Until radically new types of batteries appear, any cordless tool will remain in the niche of auxiliary devices. In this case — for 13 minutes.

Care

To keep the tool looking presentable and working efficiently, after use it is enough to wipe it and remove dust. It is also important to pay attention to the removable mesh filters located on both sides of the grinder body.

Batteries should be stored separately, in a warm room, and recharged regularly.

Battery

Our tool is supplied with two 18-volt, 5 Ah batteries and one charger. The battery charge takes about 90 minutes.

All of this brand's tools run on the same batteries, which is a smart approach that most manufacturers are currently using. Those who don't follow this practice risk losing customers who prefer other companies. These companies don't make money by selling different types of batteries, but by the high quality of their products.

Conclusions

DCK KDSM04-125 is a convenient tool for short-term work without the need to connect to the power grid. A powerful brushless motor allows you to cut and grind various materials. The grinder is equipped with an adjustable speed of rotation of the nozzle, a large handle and three levels of protection that turn off the engine power in case of jamming, overload and falling.

Pros:

- speed adjustment

- keyless mechanism for fixing the casing position

- ability to rotate the head 180°

- protection against accidental restart when replacing the battery

- automatic motor shutdown when jammed, dropped, overloaded

Cons:

- not noted