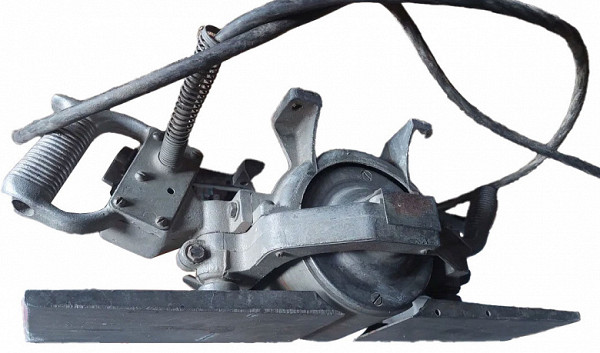

In the old days, every pioneer (probably) wielded a plane as skillfully as a chisel or chisel. True, planes in those days were not electric at all. They were like this.

Of course, electric units were also in use, but they were extremely heavy, inconvenient to use, energy-consuming and noisy machines that were used exclusively in industrial enterprises. In addition, they operated from a three-phase power supply.

Over time, we have become accustomed to affordable and compact electric tools that are convenient, with the exception of the constantly getting in the way of the electrical cord. It always hangs behind the tool, interfering with proper work. But technological progress does not stand still: modern batteries are now able to provide enough energy to run powerful engines, which allows us to say goodbye to wires.

Characteristics

| Manufacturer | Makita |

|---|---|

| Model | KP001GZ |

| Type | Cordless planer |

| Engine | brushless |

| Speed | 10000—31000 rpm |

| Planing width/depth | 82/4 mm |

| Rebate planing | yes, up to 25 mm |

| Chamfering | yes, V-grooves on the sole 1.4, 3 and 4 mm |

| Adjusting the planing depth | manual in 0.1 mm increments |

| Processed material | tree |

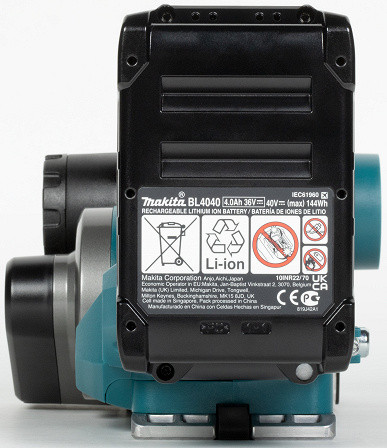

| Nutrition | Makita Li-Ion battery, XGT series 40 V |

| Other characteristics |

|

| Dimensions, weight |

|

Equipment

The plane comes in a regular cardboard box in a branded color.

The set includes a basic set of accessories: a guide (made of shiny metal with a screw), a corner for adjusting the depth (black metal with a slot and a wing screw), a plastic holder for sharpening knives and instructions.

Design and control

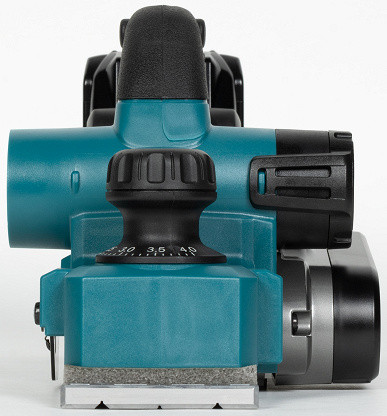

Planing width is the most important parameter for this type of tool. Typically planes are selected by width rather than length. Standard household planes have blade widths ranging from 60 to 110 mm, with the most common width being 82 mm. Our tool is exactly this width.

When it comes to length, this plane stands out from its peers. The metal base here has an impressive length of 300 mm, and the entire body with the installed battery is about 400 mm. Although this is not a jointer, our tool can no longer be called an ordinary plane.

To imagine the difference with an ordinary modest electric planer, which has a similar planing width, compare their dimensions:

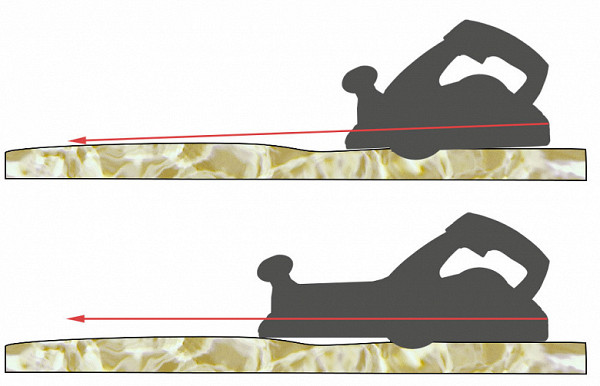

The advantage of a long sole is obvious: a large supporting area contributes to a more even surface treatment. While a short plane can follow the curves of a board or beam, a long plane will effectively smooth out any bulges, if not on the first pass, then certainly on the second pass.

Despite its unusual length, this plane is otherwise not much different from similar models. It's difficult to make dramatic improvements to established designs without risking deterioration—and that's not Makita's style.

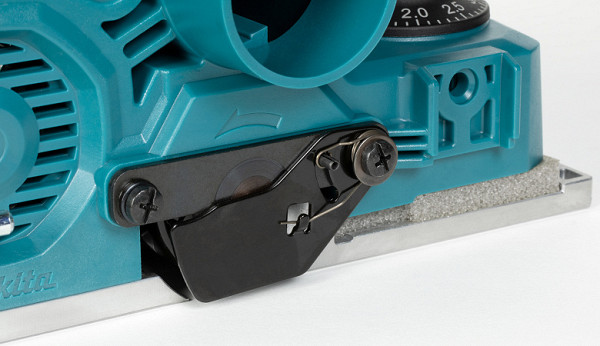

However, the tool in question still has several features that set it apart from others, especially in terms of security. An example of such a feature is a spring-loaded support tongue. This device automatically extends when the plane is lifted above the surface being processed, allowing it to be placed back on the material not with the blades down, but with a support. This prevents damage to the knives and the material being processed. As soon as the plane begins to move, the support is removed and the knives gently come into contact with the wood.

The second protection is a spring-loaded curtain that always covers the shaft with knives on the right side.

If there were no curtain, the open end of the shaft with a sharp knife could catch something during work, or some object that was in the work area could wrap around it.

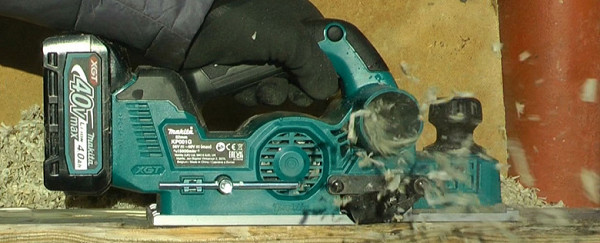

The transmission of rotation from the engine to the working shaft with knives is carried out through a belt drive. The gears and the toothed belt stretched over them are protected by a side casing, which has a special window at the bottom. This window serves to prevent the accumulation of dust, sawdust and shavings inside the mechanism. If a lot of debris accumulates, you can easily clean the mechanism by removing the protective casing, which is secured with just one bolt.

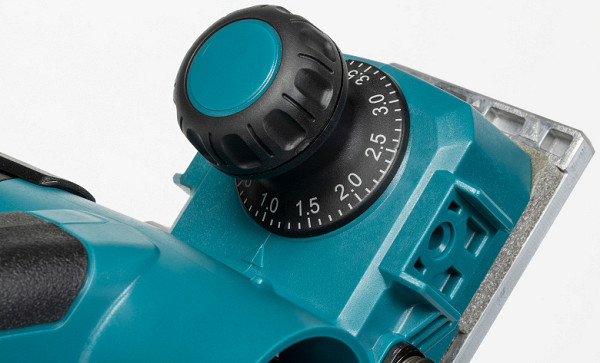

Adjustment of the planing depth in this plane is carried out in a standard way for many similar tools: by turning the front handle. Since the handle is also used to control pressure during operation, it requires some effort to turn. However, with practice it becomes easier: turning the handle counterclockwise will reduce the planing depth, and turning it clockwise will increase it.

Some users may mistakenly think that in electric planers the depth of planing is adjusted by the position of the knife, as it was in ancient hand planes. However, it is not. Modern electric planers use a different mechanism: the shaft with knives is fixed motionless relative to the body, and the height of the front part of the sole is adjusted. This creates a kind of «ladder» of blades, where the higher front of the sole results in a deeper bite into the wood.

Some users may mistakenly think that in electric planers the depth of planing is adjusted by the position of the knife, as it was in ancient hand planes. However, it is not. Modern electric planers use a different mechanism: the shaft with knives is fixed motionless relative to the body, and the height of the front part of the sole is adjusted. This creates a kind of «ladder» of blades, where the higher front of the sole results in a deeper bite into the wood.

To start the engine, you must press the start lever, having previously depressed the safety button. This button is accessible from both the left and right side of the rear handle. Thus, the instrument is suitable for both right- and left-handed people.

But what to do with the ejection of chips? If the plane is used by left-handed people, chips may fly in their direction, but here the manufacturer has provided a solution to this problem. Waste discharge is carried out simultaneously in both directions, both left and right. You just need to block the unused pipe using a special plug. If the user is left-handed, then during operation he will be to the right of the tool, so the right pipe is blocked, and the chips exit through the left ejection. If the tool is used by right-handed people, the left pipe is blocked. Simple, effective and convenient.

By the way, you can connect a vacuum cleaner hose to these pipes, which will significantly reduce the amount of debris around the workplace and reduce the risk of fine dust getting into the respiratory tract. This is especially important if work is carried out indoors. In this case, using a vacuum cleaner becomes a necessity. And to make the process even more convenient, you can use a smart vacuum cleaner that automatically turns on along with the plane. This is possible thanks to Makita AWS technology. To connect the plane with the vacuum cleaner, you will need an additional accessory — the WUT01 Bluetooth adapter, which is inserted into the slot under the control panel of the wireless module.

The two knife blades are secured to the shaft using three bolts for which a spanner is provided. It is important to purchase quality blades as replacing them will be rare unless you are working with materials that contain nails or other metallic particles. When installing the blades, the angle and depth of the seat must be strictly observed, and the bolts should be tightened starting from the center.

The planer comes with additional accessories that simplify certain operations: a guide ruler and a planing depth guide. These accessories can be attached to both the right and left.

Instructions

Instead of expressing criticism, we offer two versions of the instructions in PDF format: one contains illustrations (1), and the other contains a text part in Russian (2). This organization provides convenience to the user by providing options to first view the images and then read the explanations.

In general, the instructions can be described as quite informative. It contains not only the required sections on certifications and safety measures, but also useful practical tips and descriptions of working techniques.

Exploitation

The planer in question is equipped with soft start technology, which significantly increases operational safety. A smooth start prevents the tool from being pulled out of your hands and damaging the surface being processed if the knives are already touching the material. In addition, the planer is equipped with an electric motor brake, which makes it easier to wait for the shaft with knives to come to a complete stop. These features are clearly demonstrated in the comparison video.

As you can see, a regular plane takes as much as 4 seconds to come to a complete stop, while our tool does it in one second.

Previously, we discussed the tongue support, which prevents vertical contact of working knives with the surface being processed.

The idea is good and effective, but it only works if planing starts not from the edge of the part, but somewhere in the middle. If you start planing from the edge of a board or beam, the support-tongue may push too hard against the edge of the part, causing a slight “clog.” Here's what it looks like in practice:

The choice of planing depth depends on many factors, such as the initial quality of the surface, the hardness of the wood, its moisture content and others. However, it is recommended to avoid immediately setting the maximum planing depth. In most cases, the desired result is not achieved on the first pass. Despite the standard speed of the shaft with knives, it is about 14,000 rpm (the numbers that can be seen in the next photo should be divided by two, since the laser records reflections from two knives).

It is generally accepted that a plane with a speed in the range of 11-13 thousand revolutions per minute is intended for rough processing of wood, while a tool with 15-18 thousand revolutions allows for finishing processing. Our plane falls in the middle of this range, with the ability to maintain a given speed under load.

The front of the sole of each plane is chamfered, like a slight bevel, to prevent the tool from digging into uneven areas of the workpiece as it moves forward. The shape and size of the chamfer can vary: from high and rounded to straight with sharp corners, like the plane in question, while the height of the chamfer does not exceed two millimeters.

Due to the shape of the chamfer and its low height, the plane can rest even on small elevations during operation. If a knot or other unevenness gets in the way, you have to lift the front of the tool to get through this area.

Unfortunately, without the necessary (smart) vacuum cleaner with the appropriate adapter for connecting to the outlet pipes of the planer, it is not possible to evaluate the convenience of working with the connected vacuum cleaner.

However, the effectiveness of using a vacuum cleaner when working with planing is questionable. A plane, unlike a jigsaw or router, is most often used for processing large parts, long boards, beams, etc. It is difficult to imagine how a vacuum cleaner will effectively move parallel to the plane if the length of the board being processed reaches two or three meters or even more. Even if you use a very long and flexible hose, the suction efficiency of the vacuum cleaner may be reduced. This is due to the fact that the suction line of a vacuum cleaner has different properties from the pressure line, and the suction power decreases non-linearly with increasing distance that the air must travel.

Care

Unlike many other tools, a plane requires careful maintenance. This is due to the nature of the debris generated during operation. Wood dust and its small particles accumulate into a wet mass, filling the internal cavities of the tool and the technological recesses on its body. It is recommended to regularly remove this debris before it has time to harden. It is also important to store the plane in a dry, frost-free area. Particular attention should be paid to the battery: it must be stored only in a warm room and recharged regularly.

conclusions

Like many high-power cordless tools, the planer is not designed for large-scale work. Even the most capacious battery will not have enough energy to perform a serious amount of work. The main purpose of such a tool is to quickly process wooden surfaces in conditions where preparation of the workplace is not required. In such situations, the key factor becomes autonomy of operation, freedom from dependence on mains power.

However, beyond this, other positive characteristics are also important. Smooth start and electric brake, maintaining speed under load, a protective lever, three-dimensional V-shaped chamfering grooves, keyless installation of stops — all these qualities make the Makita KP001GZ planer an excellent representative of the professional class of tools.