When choosing DCK equipment for review, we came across an interesting and non-standard solution. A hammer drill is a tool that seems pretty mundane. However, in this case, the DCK rotary hammer stands out among its analogues due to its modular design, where the removable unit performs an important additional function.

Looks impressive, doesn't it? And coupled with this “sight” it completely resembles a non-existent futuristic weapon.

Characteristics

| Manufacturer | DCK |

|---|---|

| Model | KRH20V-26 |

| Type | cordless hammer drill |

| Engine | brushless, vertical |

| Operating modes | drilling, hammer drilling, chiselling |

| Idle speed |

|

| Number of strokes, energy | up to 5100 beats per minute, 2.8 J |

| Maximum drilling diameter |

|

| Cartridge | SDS Plus |

| Reverse | yes, electronic |

| Speed control | yes, with the start lever |

| Other characteristics |

|

| Dimensions, weight | 490×245×90 mm, 5.16 kg with vacuum cleaner attachment and battery |

| Type of batteries used | 18 V |

Equipment

The hammer drill is supplied not in a case, but in a large box. Inside the box we found a soft case-bag, which conveniently holds both the tool itself and the dust collector attachment.

The hammer drill kit includes printed materials, a dust collection attachment with filters, a removable handle, a metal drill depth limiter, a tube of branded translucent drill lubricant, a cleaning cloth, two dust collector attachments, two batteries and one battery charger.

At first sight

The tool cannot be called compact. The vertical placement of the engine allowed the length of the body to be reduced, but the height was impressive. Essentially, the tool almost forms a square.

Thanks to proper weight distribution, the hammer drill is securely held in the hands. The rotating handle can be fixed at any angle, allowing you to work in different conditions.

Different, but not quite. There are situations when you need to drill a hole in a corner or next to some kind of protrusion. Here you need to get creative by turning or completely removing the additional handle.

The hammer drill is equipped with a lower backlight, which provides more effective illumination of the work area compared to the backlight located higher and closer to the working body.

The backlight does not turn off instantly when you release the lever; it remains on for another 10 seconds. This is very convenient because in the dark the tool can act as a flashlight.

However, if you use a block to remove dust, forget about the backlight: the dust collector attached to the rotary hammer blocks the beam.

It is important to note another key property of the tool: the vibration absorption system. The damper, located in the upper part of the handle and representing a rubber accordion, effectively reduces vibrations. Despite its rigidity and small stroke (up to one centimeter), the system copes well with amplitudes that can be harmful to the hand.

Battery

The hammer drill runs on an 18-volt battery; the kit includes two such batteries with a capacity of 6 Ah each. The batteries are equipped with a built-in indicator of the remaining charge.

Charging the battery takes 95 minutes. That's pretty fast for a battery of such high capacity.

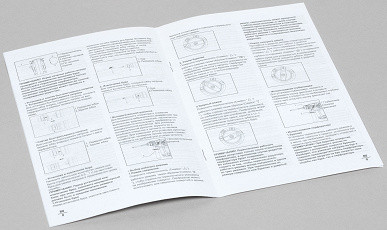

Instructions

Three instructions are included with the hammer drill: for the hammer itself, for the dust collector and for the charger. The documents are written in detail and contain useful information, including operating and safety recommendations.

Management, operation

The direction of rotation of the drill is controlled by a rocker lever, as is usually done in drills and screwdrivers. In the middle position, the lever locks the spindle, which is recommended for tool storage. The mode switch has four positions: drilling, hammer drilling, chiselling and chisel rotation mode. The latter allows you to manually rotate a chisel (shovel or other attachment) inserted into the chuck to the desired angle.

The start lever is pressed with moderate force and has a stroke of 8.5 mm. The first one and a half millimeters is idling, with further pressing the flashlight and vacuum cleaner (if connected) turn on, and at 3 mm the engine starts. Thus, less than 6 mm of lever travel remains to adjust the spindle speed.

Unlike drills and screwdrivers, hammer drills use attachments with a shank chambered for SDS Plus. This shank is not smooth and even, like that of drill bits, and not hexagonal, like that of screwdriver bits. It has four slots: two open for guide wedges and two closed for locking locking balls. The SDS Plus shank diameter is always 10 mm, regardless of the drill bit diameter.

The drill bit with SDS Plus shank fits quickly and easily into the chuck: just insert it, turn and press. The name SDS (Steck Dreh Sitzt) is translated from German as “insert, turn, secure.” Removing the drill is also simple: you need to slightly pull the middle spring-loaded part of the cartridge towards the body.

We would like to remind you of an important aspect that is often ignored or simply not known. It's about lubrication. Before each job, it is important to lubricate the drill shank to prevent early wear of the locking lugs in the chuck and grinding off of the longitudinal grooves of the drill. This is what a worn drill shank looks like:

Such equipment cannot be used — the drill may fly out of the chuck and cause injury. The shank must be lubricated before each work session, regardless of the type of work, be it drilling or chiselling. Lubricant should be applied liberally, paying particular attention to the grooves. Excess lubricant that has come out of the cartridge must be removed with a cloth so as not to stain the walls during operation.

If there is dusty work to be done indoors, using a vacuum cleaner becomes necessary. Typically, one person drills into the wall while the other holds the vacuum cleaner tube. However, with our hammer drill there is no need for an assistant thanks to a special dust collection attachment.

The dust collection attachment, which has dimensions similar to a rotary hammer, is easily attached to the tool, forming a durable one-piece structure. However, it is worth noting that the additional handle can only be turned sideways or up, but not down.

The dust collector unit is a built-in vacuum cleaner that operates depending on the activity of the connected tool. Inside the block there is a motor powered by the same battery as the hammer drill, as can be seen in the photo with two terminals. There is also a dust bin with a paper filter to collect dust.

The retractable hollow bracket, at the end of which there is a dust collection nozzle, is a telescopic spring-loaded tube.

Levers and buttons allow you to set the desired drilling depth in advance.

The dust extractor attachment has a unique design: it is hollow inside and has a soft tip on the front that fits tightly against the wall or other surface while drilling.

On the back side of the nozzle, facing the operator, there is a brush directed inward, which covers the drill, drill and other equipment, preventing dust from escaping.

As a result of the operation of the vacuum cleaner, the air it captures along with dust enters from the working area directly into the collection compartment, being cleaned through the filter.

It is noteworthy that the vacuum cleaner motor is activated before the spindle begins to rotate and continues to work for a few seconds after the rotary hammer is turned off. Now let's see how effectively the vacuum cleaner attachment copes with the task.

With such a tool, you can safely drill into walls in rooms with expensive carpets without worrying about dust.

Let us remind you how a hammer drill differs from an impact drill. In an impact drill, the reciprocating motion of the drill is achieved using a ratchet, which is ineffective and wears out quickly. The hammer drill uses a crank mechanism that converts the rotation of the engine into a reciprocating motion transmitted to the piston. The piston, in turn, acts on the firing pin, which knocks on the spindle through an air gap that reduces recoil and the load on the piston.

This mechanism is much more efficient and durable than a ratchet, although it is more expensive. Now let’s compare the efficiency of drilling in two modes: non-impact and impact. It seems that captions in the video indicating the drilling mode are not needed here.

In conventional drill mode, the tool seems to be low-powered, while in hammer drilling mode, the hammer drill copes with the task in a matter of seconds. The same result can be expected when drilling into any other material similar in strength to brick, including concrete. A hammer drill with a real impact mode almost does not react to the strength and density of the material.

Rotary hammers that use a crank mechanism for impact do not depend on the number of spindle revolutions, unlike impact drills. In hammer drills, drilling efficiency is achieved not so much by the speed of rotation of the drill (drill), but by the force of impact.

Therefore, the rotation speed in rotary hammers is low. According to the passport, the maximum number of revolutions is 1125 rpm; in our measurements, the speed turned out to be slightly higher — 1150 rpm.

In chiselling mode, the attachment does not rotate. The effectiveness of this mode largely depends on the type of attachment used. Different attachments are designed for different operations: the spatula is suitable for leveling the surface or gating (making depressions and grooves), and the peak is used for destruction. However, with enough experience, a paddle can be just as effective as a pike, and sometimes even more so. It is important to know where and at what angle to apply the force.

In terms of feel and performance results, the tool’s performance is comparable to powerful corded hammer drills. The absence of wires greatly simplifies the work, but you have to pay for mobility: the battery life of such powerful tools does not exceed 20 minutes.

Care

A hammer drill can create a significant amount of debris, especially in chiseling mode. Without a vacuum cleaner, most of the dust goes to the side, but some settles on the body of the tool. Therefore, after each dusty session, it is recommended to clean the case from dust, especially cement and plaster. The tool should be stored in a dry, frost-free room. Batteries require special attention: they must be stored at positive temperatures and periodically recharged.

sonuçlar

The DCK KRH20V-26 is a unique instrument that stands out in both performance and quality. Its powerful brushless motor, bottom light, chiseling mode, built-in anti-vibration system and vacuum cleaner attachment make it a worthy representative of the professional segment.