Passport specifications, delivery set

| Manufacturer | DeepCool |

|---|---|

| Model | LD360 |

| Model code | R-LD360-BKMSN-G-1; EAN: 6933412728726 |

| Cooling system type | liquid closed type prefilled non-expandable for processor |

| Compatibility | motherboards with processor sockets: Intel: LGA 1700 /1200/1151/1150/1155; AMD: AM5/AM4 |

| Fan type | axial, 3 pcs. |

| Fan model | FD12 ARGB (DF1202512CM) |

| Fan power supply | Motor: 12V 0.22A; Backlight: 5V 1.05W (7-pin connector: common, motor power, rotation sensor, PWM control, common, backlight data, backlight power) |

| Fan dimensions | 120×120×25 mm |

| Fan speed | 600-2400 rpm |

| Fan performance | maximum 122.4 m³/h (72.04 ft³/min) |

| Fan static pressure | maximum 34.1 Pa (3.48 mmH2O) |

| Fan noise level | 38.71 dBA maximum |

| Fan bearing | Hydrodynamic (Hydro Bearing) |

| Fan service life | no data |

| Radiator dimensions | 402×120×27 mm |

| Radiator material | aluminum |

| Hose material | no data |

| Length of hoses | 410 mm |

| Pump | integrated with heat sink |

| Pump rotation speed | 3400 rpm |

| Pump dimensions (L×W×H) | 89×78×53 mm |

| Pump power supply | Motor: 3-pin connector (Common, Power, Rotation Sensor, 12V, 0.35A); Light: 3-pin connector (Addressable LED Light: Common, Data, Power, 5V, 2.55W) |

| Pump noise level | no data |

| Pump service life | no data |

| Heat sink material | copper |

| Thermal interface of heat sink | applied thermal paste |

| Peculiarities |

|

| Scope of delivery |

|

Description

The DeepCool LD360 liquid cooling system comes in a medium-thick corrugated cardboard package. The box contains a dust jacket with a color image of the product and a list of the main technical characteristics. Also included is a description of the anti-leakage system, which includes a built-in hydraulic shock absorber in the radiator, and other additional information. Most of the inscriptions are in English, but a link to the company's website for additional information is duplicated in several languages, including Russian. A foam polyethylene mold, a cardboard cover for the radiator, and plastic bags are used to protect and organize the parts. Accessories are packed in a cardboard box, and the documentation is in a cardboard envelope. The heat sink base and thermal paste on it are protected by a shaped overlay made of transparent plastic.

Inside the box is what is listed in the table above:

The installation instructions and warranty information are presented in the form of booklets of good printing quality. The information in the instructions is mainly illustrated and does not require translation. The company's website also provides a description of the system and a link to a PDF file with the installation instructions.

The system is sealed, filled and ready for use. The pump is integrated into a single unit with a heat sink. The base of the heat sink, which is in direct contact with the processor cover, is made of copper. The outer surface of this plate is smooth, ground and slightly polished, and towards the center it is convex with a difference of about 0.2–0.3 mm.

The dimensions of this plate are 54x54 mm, and the internal area limited by the screw holes is approximately 40x40 mm. The central part of the plate is initially covered with a thin layer of thermal paste.

Unfortunately, there is no thermal paste for recovery in the package. Thermal paste of a different manufacturer with similar quality was used in the tests.

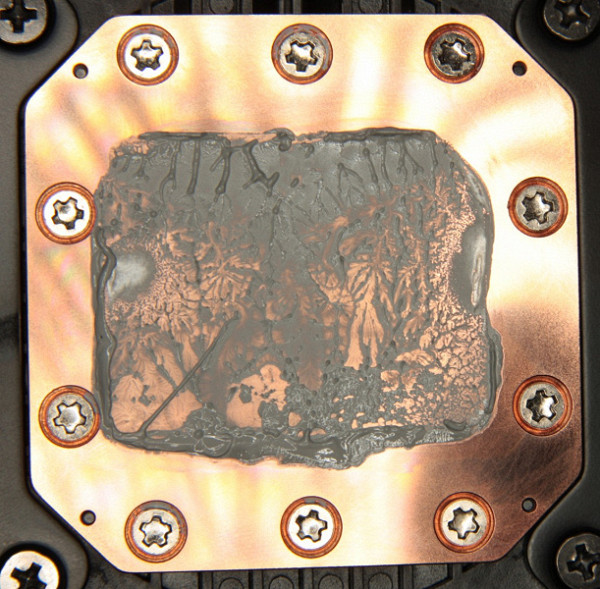

Looking ahead, let's present the distribution of thermal paste after completing all tests on the Intel Core i9-13900K processor:

And on the sole of the pump:

The thermal paste was evenly distributed in a thin layer over the entire surface of the processor cover, with the excess squeezed out over the edges. The tight contacts are concentrated at the edges, which looks strange given that the processor cover is slightly convex towards the center. (It is worth noting that the distribution of the thermal paste changed when the processor and pump were separated.)

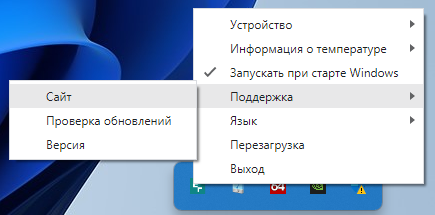

The pump cover is made of a translucent material. Along the perimeter, under the cover, there is a light diffuser illuminated by several addressable RGB LEDs controlled via a three-wire interface. In the central part, under the cover, there is a segment LED display controlled via USB. It displays the current processor consumption, its temperature, and the system load. For this indicator to work correctly, the DeepCool DIGITAL program must be installed in the system, access to a number of settings is carried out through the menu called by clicking on the icon.

The length of the power cable from the pump is 25 cm, the backlight cable is 42 cm (plus 10 cm to the feed-through connector), and the USB cable for connecting to the block on the system board is 65 cm.

The hoses are elastic and relatively flexible, enclosed in a braid made of slippery plastic; their outer diameter with braid is about 12 mm. The length of the flexible part of the hoses excluding the crimping sleeves is 38.8 cm, which is quite long. The L-shaped fittings at the inlet to the pump rotate, which makes it easier to install the system. The package includes two ties with Velcro to fix the hoses and give the system a neater look.

The radiator is made of aluminum and has a matte black coating, which is quite resistant to external influences. The maximum thickness of the radiator with installed fans is 54 mm.

The fan frame is made of durable black plastic.

The lugs in the corners of the fan frame are equipped with vibration-isolating rubber pads, which in an uncompressed state protrude approximately 1 mm relative to the plane of the frame. According to the developers, this should provide vibration isolation of the fan from the mounting point. However, if we take into account the ratio of the fan mass and the rigidity of the pads, it becomes obvious that the resonant frequency of the design is very high, which makes vibration isolation virtually impossible. In addition, the sockets for the mounting screws are part of the fan frame, so vibration from the fan is transmitted to the radiator through the screws without any interference. Thus, such a design of the lugs can be considered more as an element of the fan design than as an effective solution for reducing vibration.

The fan impeller is made of white translucent plastic. Several ARGB LEDs are located around the fan stator, which illuminate the impeller from the inside.

The fan is equipped with a built-in 7-pin connector (the block has eight contacts, but one contact is missing). The fans installed on the radiator are connected in series using a special 50 cm long cable from the outer fan, which ends with two connectors: one for connecting to the system board and the other for a pass-through connection of the backlight on the cable from the pump. This connection method ensures neat assembly of the system and minimizes the number of wires and connectors that require laying inside the case. However, replacing the fans with models with a conventional connection can disrupt this neatness.

The operation of the pump and fan backlight (default mode when connected to the system board) and the indication on the pump display are demonstrated in the video below:

The assembled system with fasteners for LGA 1700 weighs 1674 g. The fasteners are made mainly of hardened steel and have a durable galvanic or paint coating. The frame, placed on the back side of the system board, is made of durable plastic and equipped with steel threaded posts.

Testing

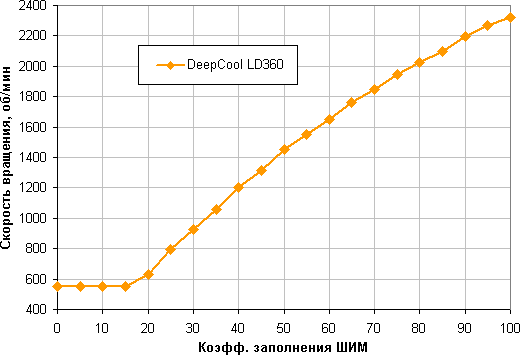

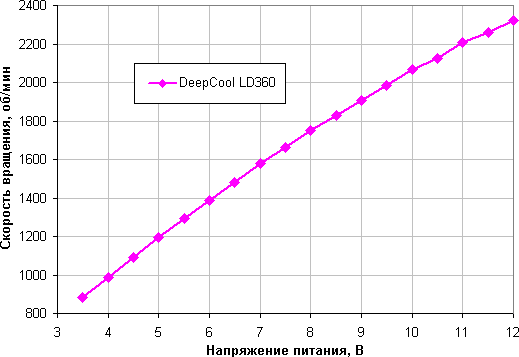

Determining the dependence of the cooler fan speed on the PWM duty cycle and/or supply voltage

A good result is shown by a monotonous increase in rotation speed when changing the fill factor from 15% to 100%, providing a wide adjustment range. When the fill factor (FF) decreases to 0%, the fans do not stop, which may be important for users seeking to create a hybrid cooling system that operates completely or partially in passive mode at low load.

Adjusting the fan speed with voltage ensures stable operation in a narrower range. They stop when the voltage drops to 3.2-3.4 V and start at 3.4-3.5 V. The fans can be connected to a 5 V source.

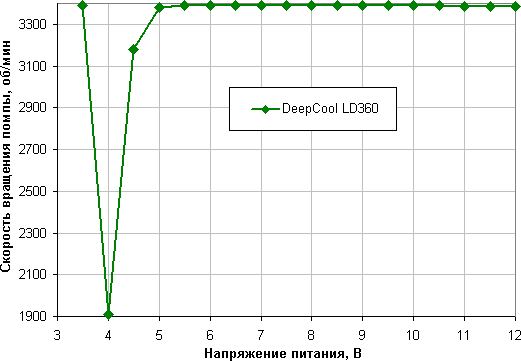

As for the pump, its speed is almost impossible to adjust by changing the supply voltage, since it is stabilized in a wide range of voltage changes.

The pump stops at 2.9 and starts at 3.9 V. It is also acceptable to connect the pump to 5 V, but there is no point in this.

Determining the dependence of the processor temperature at full load on the rotation speed of the cooler fans

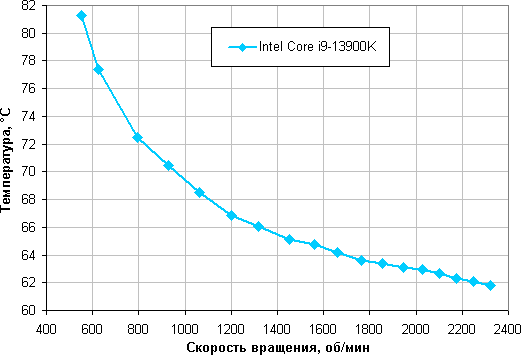

In this test, all cores of the Intel Core i9-13900K processor operated at 4.1 GHz. During load tests and noise measurements, the fan speed was adjusted using PWM in the range from 100% to 15% in 5% increments. The pump operated at 12 V.

In this test, the Intel Core i9-13900K processor did not overheat at an ambient temperature of 24 degrees and a fan speed achieved with a fill factor of 15%, which corresponds to about 550 rpm. The maximum consumption according to monitoring data was about 214 watts, and according to the processor power connectors — 271 watts. For reference, the base power of this processor is 125 watts, and the standard maximum short-term (turbo limit) is 253 watts.

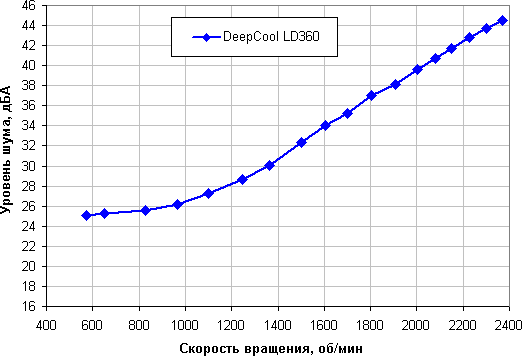

Determining the noise level depending on the rotation speed of the cooler fans

The noise level of this cooling system varies widely. It depends on individual characteristics and other factors, but in general the noise level is from 40 dBA and above, which is considered quite high for a desktop system. The noise level in the range of 35-40 dBA can be considered tolerable, while at values below 35 dBA the noise from the cooling system will not stand out significantly against the background of ordinary PC components, such as case fans, power supply fans, video cards and hard drives. At a level below 25 dBA the cooler can be considered relatively silent. The background noise level was 16.8 dBA (according to the sound level meter). The pump is quite loud — about 25 dBA, and it is difficult to reduce its rotation speed, which makes it the main source of noise in the system.

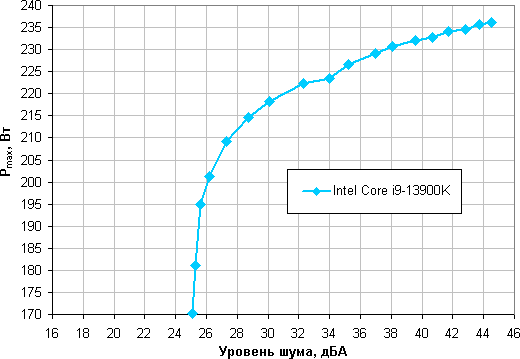

Plotting the dependence of the actual maximum power on the noise level

Let's try to move from the test bench conditions (24 degrees of ambient air) to more realistic scenarios. Let's assume that the temperature of the air taken in by the cooling system fans can reach 44 °C (for example, if the liquid cooling system is installed to blow out of the case with a powerful video card). At the same time, we would not like the processor temperature under maximum load to exceed 80 °C. Given these parameters, let's plot the dependence of the real maximum processor power (designated as Pmax, previously the designation Max. TDP was used) on the noise level.

Taking 25 dBA as the criterion of conditional silence, we can estimate the maximum power of processors corresponding to this level. Under certain conditions, this will be approximately 170 W for the Intel Core i9-13900K processor. If we ignore the noise level, the power limits can be increased to approximately 236 W. Recall that these values were obtained under conditions of intensive blowing of the radiator with heated air up to 44 ° C. With a decrease in air temperature and / or an increase in the maximum permissible processor temperature (which can reach 100 ° C), the specified power limits for silent operation and maximum power will be higher.

Comparison with other liquid cooling systems when cooling the Intel Core i9-13900K processor

It is worth noting that when switching to testing on the new Intel Core i9-13900K processor, it is not possible to fully maintain continuity with previous tests. However, according to preliminary data, the efficiency of coolers with the Intel Core i9-13900K is approximately 20% lower than with the Intel Core i9-7980XE processor, which was used in the previously conducted series of tests. This makes it possible to compare the results with coolers and liquid cooling systems tested earlier.

Conclusions

To properly understand the findings, it is important to consider the following:

The purpose of testing is to determine the cooling capacity of the cooler (or liquid cooling system). The processors used in the tests serve only as heating elements to evaluate the thermal resistance of the cooler in various modes. Thus, the processor power is regulated depending on the capabilities of the cooling system and can be lower or higher than standard operating modes. The main thing is to avoid overheating the processor throughout the entire range of the cooler's cooling capacity, while maintaining a significant difference in processor temperature.

Based on the DeepCool LD360 liquid cooling system, you can create a relatively silent computer (noise level of 25 dBA and below) with an Intel Core i9-13900K processor, if the maximum consumption of such a processor does not exceed 170 W, and the temperature inside the case does not rise above 44 ° C, with a limitation on the maximum processor temperature of 80 ° C. The power limits can be increased by lowering the cooling air temperature, increasing the CPU temperature limit (up to 100 °C), or making noise requirements less stringent. However, the high noise level of the pump, which is difficult to reduce, makes this cooling system unsuitable for building quiet PCs. However, it is effective enough to cool the Intel Core i9-13900K in all real-world load scenarios, and the lighting on the pump and fans, as well as the display on the pump, are useful for quickly assessing the system's status. Also worth noting is the good build quality, the braided hoses, and the convenient arrangement of the electrical connections.