Specifications, delivery set

| Manufacturer | ID-Cooling |

|---|---|

| Model name, link | Frozn A720 Black |

| Model code | ID-CPU-FROZN-A720-BLACK; EAN: 6931393305783 |

| Cooling system type | for the processor, air tower type with active airflow of the radiator located on the heat pipes |

| Compatibility | mat. boards with processor sockets: Intel: LGA 1700 , 20xx, 115x and 1200; AMD: AM5, AM4 |

| Cooling capacity | TDP 300 W |

| Fan type | axial (axial), 2 pcs. |

| Fan model | TF-14025 (ID14025M12F) |

| Fan power | 12 V, 0.36 A |

| Fan dimensions | 140×140×25 mm |

| Fan speed | 500—2000 rpm |

| Fan performance | 167.5 m³/h (98.6 ft³/min) |

| Fan static pressure | 22.2 Pa (2.26 mm water column) |

| Noise level | 33.5 dBA maximum |

| Fan bearing | Fluid Dynamic Bearing |

| Fan life | no data |

| Cooler Dimensions (H×W×D) | 163×140×153 mm |

| Cooler weight | 1300 g |

| Radiator material | aluminum plates (0.4 mm thick) and copper heat pipes (7 pcs. ∅6 mm), copper heat sink |

| Thermal interface of the heat sink | Frost X25 thermal paste in a syringe |

| Connection | fans: 4-pin connectors (power, rotation sensor, PWM control) into the splitter connectors, and the splitter into the CPU cooler connector on the motherboard |

| Peculiarities |

|

| Delivery set (better to check before purchasing) |

|

Description

The processor cooler is delivered in a strictly designed box made of medium-thick corrugated cardboard.

The kit includes instructions with step-by-step illustrations and explanations in three languages: English, Chinese and Russian. Fasteners are primarily made of hardened steel (except for accessory posts and bushings) and have a durable galvanized or black paint finish.

A neat plastic box is used to pack small fasteners.

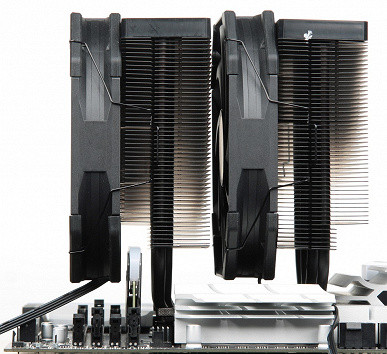

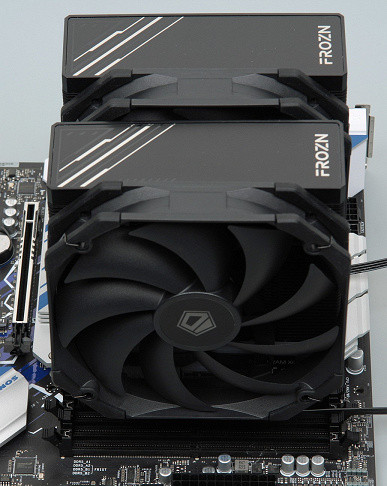

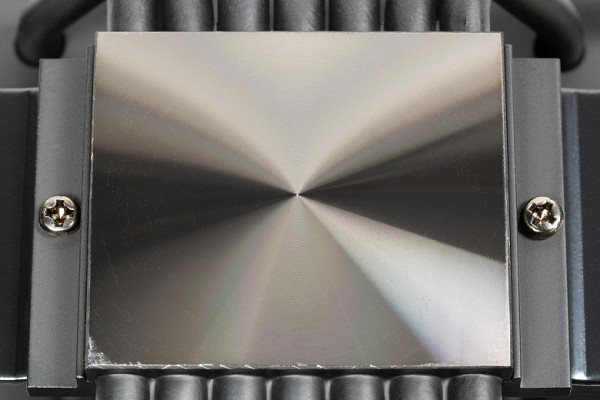

The cooler is equipped with a double remote radiator that effectively transfers heat from the processor through seven heat pipes. Copper materials are used for the tubes and the bottom of the heat stripper. The tubes, lower surface of the thermal stripper, radiator fins and some fasteners have a black semi-matte paint finish, which contributes to improved heat transfer due to radiation. The upper part of the heat remover is made of aluminum alloy. The tubes are soldered to the thermal stripper. The soleplate of the heat remover has a fine concentric texture and is lightly polished. The surface of the sole is slightly convex in the center with a difference of about 0.1 mm.

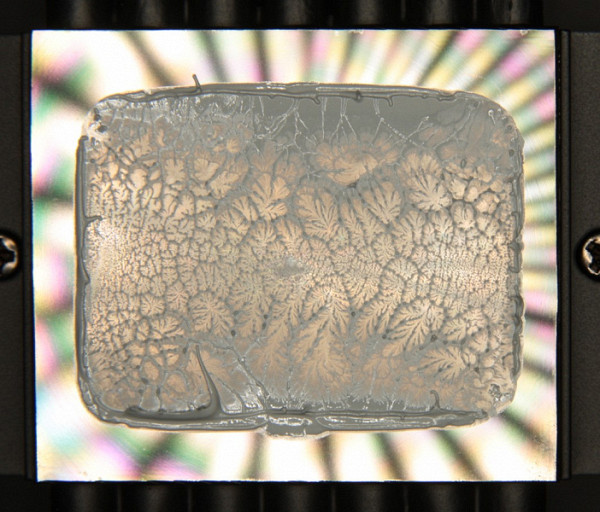

A preliminary thermal interface is not supplied, but the manufacturer included a small syringe with thermal paste in the kit with the cooler. The tests performed used high-quality thermal paste from another manufacturer. Next, we will provide a visualization of the thermal paste distribution after the tests are completed. In relation to the Intel Core i9-13900K processor:

And on the base of the heat sink:

It is obvious that the thermal paste was evenly distributed over almost the entire surface of the top cover of the processor, while its excess was squeezed out at the edges. The extensive area of tight contact is clearly visible.

The radiator consists of two stacks of aluminum plates tightly mounted on heat pipes. The tubes are arranged in a parallel pattern, which likely helps improve the cooler's efficiency. The upper parts of the plates are covered with decorative plastic covers.

Standard size of complete fans is 140 mm.

The fans are secured with typical steel brackets and support PWM control.

The dimensions of the cooler are quite large, and in the case of the LGA1700 connector, all slots for RAM are blocked on top by a radiator and fan. An example is the ASRock Z790 PG Sonic motherboard:

It is important to note that the heatsink has reduced depth fins and the external fan can be moved upward. According to our measurements, this allows the use of memory modules up to 61 mm in height. If you do not raise the fan above the radiator level, the height of the memory modules can be up to 28 mm.

It should be noted that the design of the fastening eliminates too weak or strong pressing (the nuts just need to be tightened until they stop, avoiding excessive force). Two-point clamping also reduces the possibility of misalignment.

Testing

Below in the summary table we present the results of measurements of a number of parameters.

| Cooler weight (with mounting kit for LGA1700), g | 1378 |

|---|---|

| Radiator weight only, g | 1005 |

| Heat sink platform dimensions, mm | 46×40 |

| Fan power cable length, cm | 28 |

| Fan power splitter length, cm | 20+10+10 |

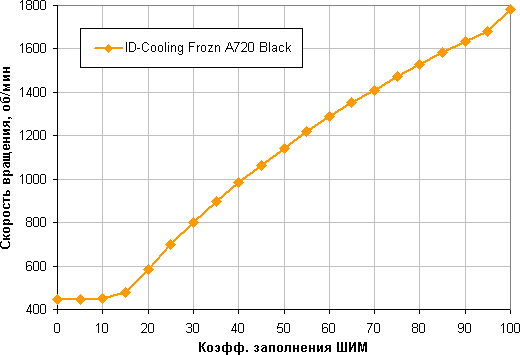

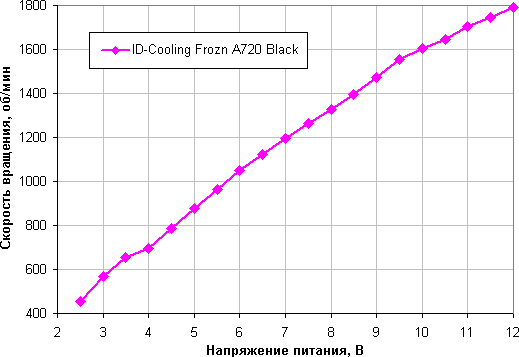

Determining the dependence of the cooler fan speed on the PWM duty cycle and/or supply voltage

A good result was obtained — the fan rotation speed smoothly increases when the fill factor (FC) changes in the range from 10% to 100%, providing a wide range of adjustment. It is important to note that with a short circuit of 0%, the fan does not stop, therefore, in a hybrid cooling system with passive mode at minimum load, such fans will have to be turned off by reducing the supply voltage.

The adjustment range using voltage in this case is approximately the same. The fan stops rotating when the voltage drops to 2.0 V and turns on when it reaches 2.6 V. Connecting the fan to a 5 V source is completely acceptable.

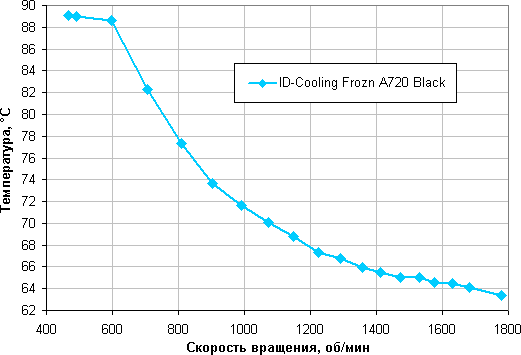

Determining the dependence of the temperature of the Intel Core i9-13900K processor when it is fully loaded on the rotation speed of the cooler fan(s)

In this test, all cores of the Intel Core i9-13900K processor ran at 4.0 GHz.

In fact, the test found that at an ambient temperature of 24 degrees Celsius, this processor begins to overheat at a duty cycle of 20% (approximately 600 rpm) and below. This is due to the fact that some cores reach a critical temperature of 100 °C, which is the limit for this processor. Under the conditions of this test, the maximum power consumption through the additional 12V connectors on the motherboard is 258 W.

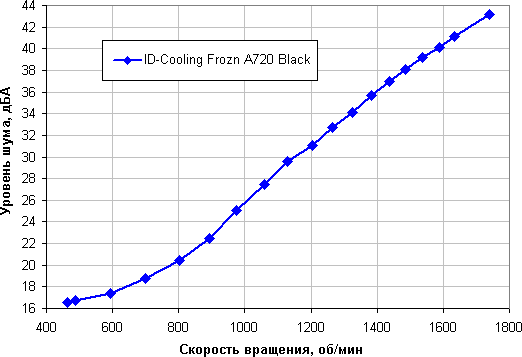

Determining the noise level depending on the rotation speed of the cooler fan(s)

This parameter, of course, may vary depending on individual characteristics and other factors. However, for coolers that produce noise levels of around 40 dBA or higher, we consider the desktop system to become quite noisy. A noise level of 35 to 40 dBA is considered acceptable. The range from 25 to 35 dBA makes the cooler relatively silent, and below 25 dBA can be considered absolutely silent. Compared to typical PC components such as case fans, power supplies, video cards and hard drives, noise levels below 35 dBA will be almost unnoticeable. It is worth noting that the background level was measured at 16.0 dBA (according to the conventional data displayed by the sound level meter). At maximum fan speed this cooler is quite noisy.

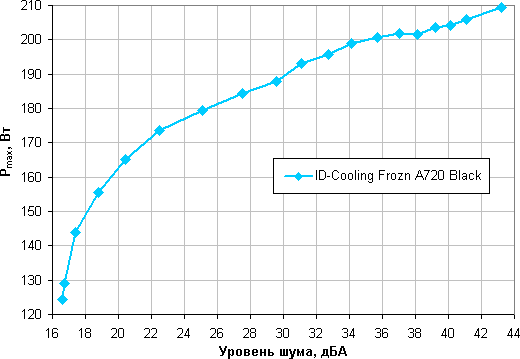

Plotting the dependence of real maximum power on noise level

Let's move on from the testbed parameters to more realistic scenarios. Assume that the temperature of the air entering the cooling fan can reach 44 °C. However, we do not want the processor temperature to exceed 80 °C under maximum load. Given these conditions, let's plot the actual maximum power (denoted as Pmax, previous notation Max. TDP) consumed by the processor versus the noise level.

Taking 25 dBA as a conditional criterion for noiselessness, we can estimate the approximate maximum power of processors, such as the Intel Core i9-13900K, at this noise level, approximately 179 W. Hypothetically, if noise levels are not taken into account, the power limits could be extended to approximately 210 watts. Note that these values are calculated under conditions of severe airflow to the radiator with air heated to 44 degrees, at a maximum processor temperature of 80°C (within the permissible range of 100°C). As ambient temperatures change or the maximum permissible processor temperature increases, the specified limits for quiet operation and maximum power may change.

conclusions

To properly understand the results, it is important to remember that:

The main purpose of testing is to determine the efficiency of the cooler's cooling system (or LSS). The processors on which testing is carried out are used exclusively as a heat source for the subsequent assessment of the conditional thermal resistance of the cooler in various modes. Thus, the power (heat dissipation) of the processor is artificially adjusted depending on the capabilities of the cooling system and can be either less or more than in standard processor operating modes. The main requirement is that the processor should not overheat within the entire range of the cooler's cooling capacity, while maintaining significant variations in processor temperature variations.

Using the ID-Cooling Frozn A720 Black air cooler, you can create a computer with conditionally silent operation (noise level 25 dBA and below), equipped with an Intel Core i9-13900K processor. To do this, it is necessary that the power consumption of this or a similar processor under maximum load does not exceed 179 W. In addition, the air temperature inside the case should not rise above 44 °C, with the maximum processor temperature limited to 80 °C. With lower cooling air temperatures, higher processor temperature limits (up to 100 °C), or less stringent noise requirements, power limits may be increased. The cooler's advantages include a neat design, while its disadvantages include limited compatibility with high-end memory modules.