Passport specifications, delivery set

| Manufacturer | DeepCool |

|---|---|

| Model name, link | Assassin 4S |

| Model code | R-ASN4S-BKGPMN-G; EAN: 6933412728696 |

| Cooling system type | for the processor, air tower type with active blowing of the radiator located on heat pipes |

| Compatibility | motherboards with processor sockets: Intel: LGA2066/2011-v3/2011/ 1700 /1200/1151/1150/1155; AMD: AM5/AM4 |

| Cooling capacity | no data |

| Fan type | axial |

| Fan model | DeepCool DFr1402512CH |

| Fan power supply | 12V, 0.2 |

| Fan dimensions | 140×140×25 mm |

| Fan speed | 500-1800 rpm (±10%), quiet mode: 500-1450 rpm (±10%) |

| Fan performance | 104.1 m³/h (61.25 ft³/min), quiet mode: 82.5 m³/h (48.55 ft³/min) |

| Fan static pressure | 36.9 Pa (3.76 mmH2O), quiet mode: 24.1 Pa (2.46 mmH2O) |

| Noise level | no more than 29.3 dBA, quiet mode: no more than 22.6 dBA |

| Fan bearing | hydrodynamic (Fluid Dynamic Bearing) |

| Fan service life | no data |

| Cooler dimensions (H×W×D) | 164×147×116 mm |

| Radiator dimensions (H×W×D) | 160×110×140 mm |

| Cooler weight | 1380 g |

| Radiator material | aluminum plates (0.4 mm thick) and copper heat pipes (7 pcs. ∅6 mm), copper heat sink |

| Thermal interface of heat sink | thermal paste in a syringe |

| Connection | Fan: 4-pin connector (power, RPM sensor, PWM control) to splitter connector, and splitter to CPU cooler connector on motherboard |

| Peculiarities |

|

| Delivery set (better to check before purchasing) |

|

Description

The CPU cooler is supplied in a box made of medium-thick corrugated cardboard. A dust jacket is put on top of the box.

The kit includes an installation manual in English, which includes a description of the warranty in several languages, including Russian. A PDF version of the manual can be downloaded from the manufacturer's website. The manual mainly consists of illustrations, so it is easy to understand even without translation.

The fasteners are made of hardened steel, with the exception of plastic spacers and standoff clamps for mounting on the back plate of the motherboard. They have a durable galvanic or paint coating.

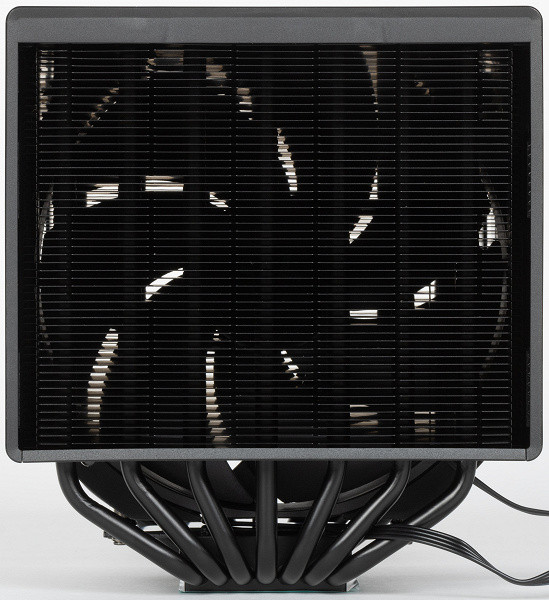

The cooler is equipped with an external double radiator, to which heat from the heat sink is transferred via seven heat pipes with a diameter of 6 mm.

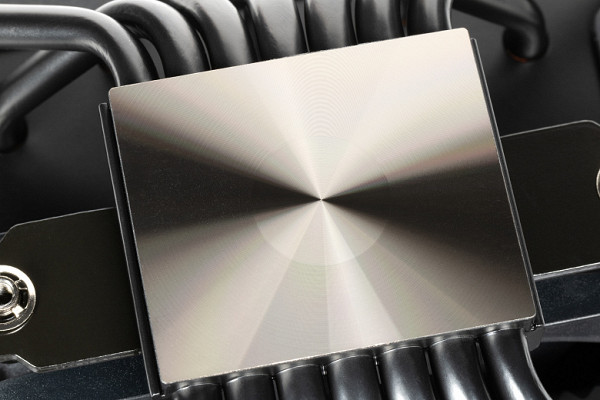

The tubes and base of the heat sink are made of copper. The tubes, the non-working surface of the base, the radiator plates and some fasteners are covered with black semi-matte paint. The upper part of the heat sink is made of aluminum alloy. The tubes are securely soldered to the base. The sole has a fine concentric groove and is slightly polished. The surface of the sole is slightly convex in the center with a difference of about 0.1 mm.

There is no pre-installed thermal interface, but the manufacturer includes a small syringe with the branded DM9 thermal paste.

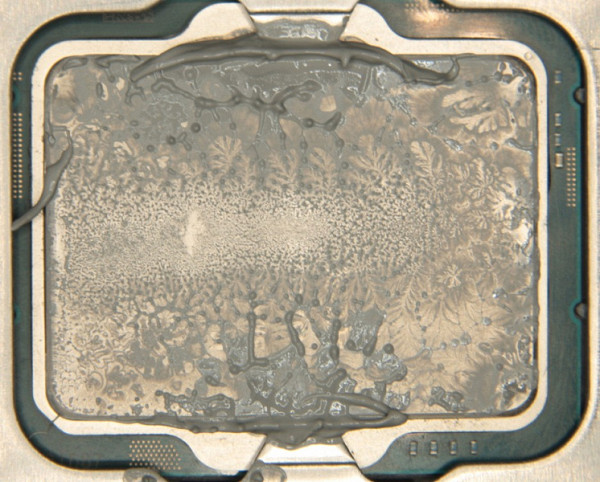

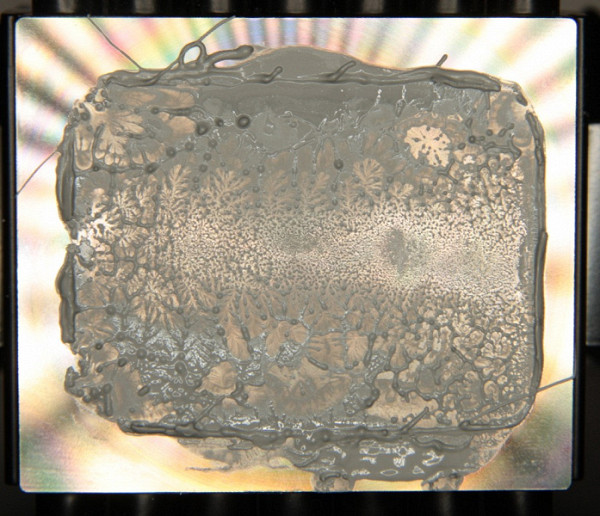

High-quality thermal paste from another manufacturer was used for testing. Looking ahead, we can show how the thermal paste was distributed after completing the tests on the Intel Core i9-13900K processor:

And on the sole of the heat sink:

The thermal paste was evenly distributed in a thin layer over the entire surface of the processor cover, and the excess was squeezed out along the edges. The tight contact zone turned out to be quite large.

The radiator consists of two arrays of aluminum plates, tightly strung on heat pipes.

The radiator design is distinguished by the fact that it is covered with plastic covers and three steel grids. The upper grid is removable, it is fixed with magnets, which allows you to easily remove it to remove the fan located between two arrays of radiator plates.

The size of the complete fan is 140 mm.

The fan supports PWM control.

When connecting the fan to the standard splitter, you can select the operating mode — productive or quiet. In quiet mode, as expected, the fan speed is reduced. The mode switch is located on top of the casing.

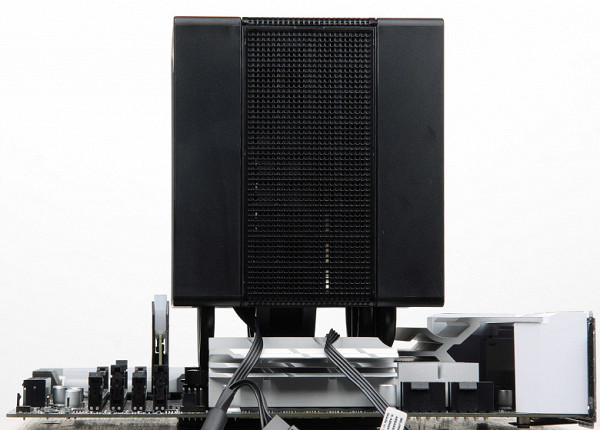

The cooler has fairly large dimensions, but when installed on most compatible sockets for Intel processors, and probably on all compatible sockets for AMD processors, the radiator does not block access to the RAM slots. Example for LGA1700:

If the radiator covers the RAM slots, then modules up to 53 mm high can be placed under it.

The cooler is quite easy to install, although you will need to remove the fan for this. You will also need a long screwdriver, which is already included in the kit. It is worth noting that the design of the fastener practically eliminates the skew of the heat sink relative to the processor cover, and also provides optimal pressure — not too weak and not too strong.

Testing

Below in the summary table we present the results of measurements of a number of parameters not specified by the manufacturer.

| Dimensions of the heat sink platform, mm (L×W) | 46×40 |

|---|---|

| Fan cable length, cm | 27 |

| Length of power strip, cm | 14.5 |

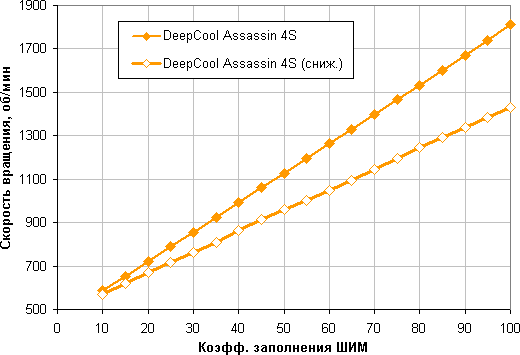

Determining the dependence of the cooler fan speed on the PWM duty cycle and/or supply voltage

The results are impressive: smooth increase in fan speed when changing the fill factor (FF) from 10% to 100% and a wide adjustment range. When the FF is below 10%, the fan stops completely, which is useful for hybrid cooling systems with passive mode at minimum load. In quiet mode, the speed reduction is indicated as «Reduce».

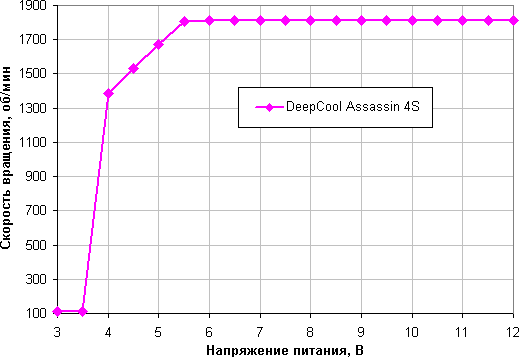

The dependence of the rotation speed on the supply voltage shows that the fan is equipped with a controller that maintains stable speed when the voltage changes from 5.5 to 12 V. This makes it difficult to regulate the speed by changing the voltage, which, however, is not a disadvantage. The fan stops at a voltage below 2.9 V and starts at 3.9 V. It can be connected to a source with a voltage of 5 V, but is it worth doing?

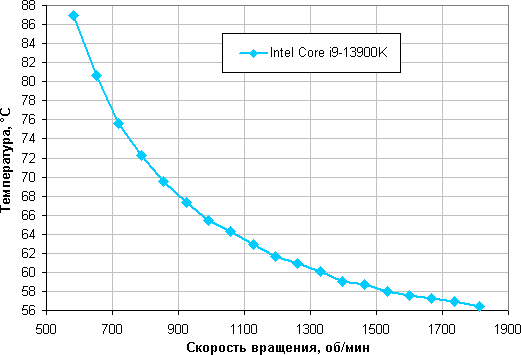

Determining the dependence of the processor temperature at full load on the rotation speed of the cooler fan(s)

In this test, all cores of the Intel Core i9-13900K processor were running at 3.7 GHz. During load and noise measurements, the fan speed was adjusted using PWM in the range from 100% to 10% in 5% increments.

Under test conditions, the Intel Core i9-13900K processor does not overheat at a fill factor (FF) of 10% (approximately 580 rpm of fans) at an ambient temperature of 24 degrees. The maximum consumption according to monitoring data was about 161 W, and according to the processor power connectors — 197 W. For comparison, the base power of the processor is 125 W, and the maximum short-term (turbo limit) is 253 W.

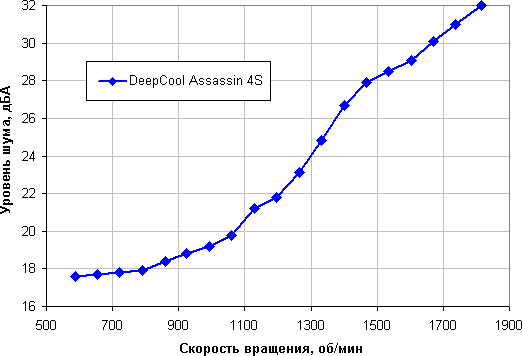

Determining the noise level depending on the rotation speed of the cooler fan(s)

Cooler noise varies depending on individual characteristics and other factors. Generally, noise levels of 40 dBA and above are considered very loud for a desktop system. Noise levels of 35 to 40 dBA can be considered tolerable, while noise levels below 35 dBA will not stand out much against other PC components, such as case fans, power supply, graphics card, and hard drives. Noise levels below 25 dBA can be considered relatively silent. The background noise level is 17.5 dBA (according to a sound level meter). In this context, this cooler can be considered a relatively quiet device.

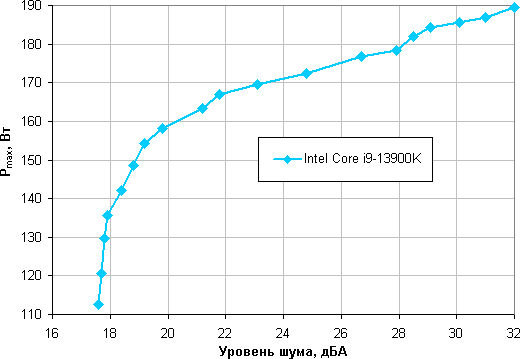

Plotting the dependence of the actual maximum power on the noise level

Let's consider more realistic scenarios, moving away from the test bench conditions. Let's assume that the temperature of the air taken in by the cooling system fan can reach 44 °C, but we would not like the processor temperature under maximum load to exceed 80 °C. Based on these conditions, we will plot the dependence of the real maximum power (designated as Pmax, previously used as Max. TDP) consumed by the processor on the noise level.

If we take 25 dBA as the criterion of conditional silence, then for processors like the Intel Core i9-13900K, the maximum power corresponding to this noise level is approximately 173 W. Hypothetically, if we do not take into account the noise level, the power limits can be increased to about 190 W. Recall that these values assume strict conditions in which the air blowing over the radiator heats up to 44 degrees. As the air temperature decreases, the specified power limits for silent operation and maximum power will increase.

Comparison with other coolers when cooling the Intel Core i9-13900K processor

It is worth noting that when switching to testing on the Intel Core i9-13900K processor, the continuity with the previous tests on the Intel Core i9-7980XE processor is not completely preserved. According to preliminary data, the efficiency of coolers for the Intel Core i9-13900K is approximately 1.2 times lower than for the Intel Core i9-7980XE. This will allow us to compare the results with coolers tested earlier.

Interestingly, the efficiency of this cooler turned out to be almost the same as that of the previously tested DeepCool Assassin IV, which differs only in the presence of a second fan.

Conclusions

To properly understand the conclusions, the following should be taken into account:

The purpose of testing is to determine the cooling capacity of the cooler (CCL). Processors are used only as heating elements to determine the thermal resistance of the cooler in various modes. The processor power is adjusted artificially to test the capabilities of the cooling system, and can be both lower and higher than the standard operating modes of the processor. The main thing is to ensure that the processor does not overheat in the entire range of the cooler's cooling capacity and a noticeable difference in the change in processor temperature.

Using the DeepCool Assassin 4S cooler, you can create a relatively silent computer (noise level of 25 dBA and below) with an Intel Core i9-13900K processor, if its maximum power does not exceed 173 W, the temperature inside the case does not rise above 44 ° C, and the processor temperature is limited to 80 ° C. With a decrease in the cooling air temperature, an increase in the maximum processor temperature (up to 100 °C) or more flexible noise level requirements, the power limits can be increased. The advantages of the cooler include a neat design, easy installation, compatibility with high memory modules and the ability to select fan modes.