Specifications, delivery set

| Manufacturer | AeroCool |

|---|---|

| Model name, link | Cylon 4 |

| Model code | Cylon 4 ARGB PWM 4P; EAN: 4718009159600 |

| Cooling system type | for the processor, air tower type with active airflow of the radiator located on the heat pipes |

| Compatibility | mat. boards with processor sockets: Intel: LGA 1700 , 1200, 2066, 2011, 115x and 775; AMD: AM5, AM4, AM3+, AM3, AM2+, AM2, FM2, FM1 |

| Cooling capacity | TDP 145 W |

| Fan type | axial (axial), 1 pc. |

| Fan model | no data |

| Fan power | 12 V, 0.6 A |

| Fan dimensions | 120×120×25 mm |

| Fan speed | 800—1800 rpm |

| Fan performance | 44.3 — 89.2 m³/h (26.1 — 52.5 ft³/min) |

| Fan static pressure | 7.1–11.9 Pa (0.72–1.21 mm water column) |

| Noise level | 14—26 dBA |

| Fan bearing | hydraulic |

| Mean time between fan failures | 60000 hours |

| Cooler Dimensions (H×W×D) | 160×127×76 mm |

| Radiator material | aluminum plates (0.4 mm thick) and copper heat pipes (4 pcs. ∅6 mm, direct contact with the processor cover) |

| Thermal interface of the heat sink | thermal paste in a bag |

| Connection | fan: 4-pin connector (power supply, rotation sensor, PWM control) into the connector for the processor cooler on the mat. board; RGB fan lighting: 3-pin connector (addressable LED lighting — general, data, 5 V power supply) via an adapter to the connector on the mat. board or controller |

| Peculiarities |

|

| Delivery set (better to check before purchasing) |

|

Description

The processor cooler is delivered in a colorfully decorated box made of medium-thick corrugated cardboard.

The delivery includes illustrated assembly instructions. Fasteners are primarily made from hardened steel, are durable and protected by a durable galvanic coating. In addition, the mounting plate on the back of the motherboard is made of durable plastic.

The cooler is equipped with an external heatsink that effectively removes heat from the processor through four copper heat pipes. The base of the heat sink is equipped with tubes that are flattened and pressed into grooves. The heat sink itself is made of aluminum.

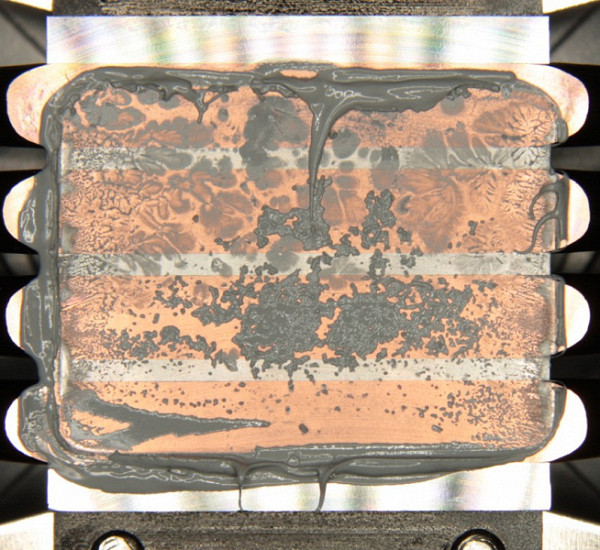

The tubes were ground flush with the base of the heat sink. The thermal paste purchased was not pre-applied, but the manufacturer included a small bag of thermal paste in the cooler kit. During testing, we used high-quality thermal paste from another manufacturer. Next, we will provide data on the distribution of thermal paste after completing tests on the Intel Core i9-13900K processor.

And on the base of the heat sink:

The thermal paste was evenly distributed over almost the entire surface of the processor cover, creating a thin layer, while excess thermal paste was squeezed out around the perimeter. The resulting tight contact spot occupies a significant area.

It is noted that the entire surface of the radiator, including plates, tubes and heat sink, with the exception of the working surface of the heat sink sole, is covered with a black semi-matte paint coating. This probably helps to improve heat transfer by radiation. The heatsink structure is a stack of aluminum plates tightly mounted on heat pipes. The heat pipes are spaced apart, which likely helps improve the efficiency of the cooling system.

Conventionally, we can assume that the standard size of the complete fan is 120 mm.

In fact, the blade diameter of this fan is approximately 5mm smaller than a standard 120mm fan. Additionally, the fan is integrated into a complex shroud that includes mounting hardware, rotating clamps, a heatsink cap, a ring diffuser, a linear diffuser, and multiple addressable multi-color (ARGB) LEDs.

After installing the radiator on the processor, the specified casing with the fan is lowered on top of the radiator and is additionally secured with twist locks. Since there is no additional pressure to the radiator, in order to avoid rattling, two porous rubber gaskets are installed in the place where the casing is pressed to the radiator. This design provides a convenient way to install the fan compared to typical steel brackets, but on the other hand, the fan on this cooler cannot be replaced with a standard one. The fan also supports PWM control.

To connect to ARGB lighting, a standard three-pin connector is used, which is located at the end of the adapter cable. The backlight mode in the standard version (without connection to the motherboard or another controller) can be seen in the presented video:

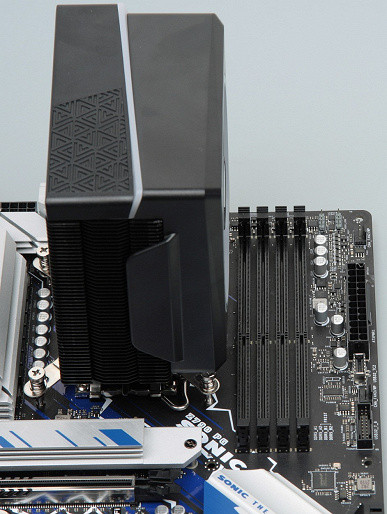

The depth of the cooler is small, so all the RAM slots at the top do not overlap. For example, in the case of the ASRock Z790 PG Sonic motherboard:

It should be noted that the design of the mounting system is somewhat unsuccessful — the screws are somewhat short and do not reach the threaded holes, which requires effort to securely fix the heatsink to the processor. In addition, a four-point mount increases the risk of improper clamping and the possibility of uneven pressure.

Testing

Below in the summary table we present the results of measurements of a number of parameters not specified by the manufacturer.

| Cooler weight (with mounting kit for LGA1700), g | 678 |

|---|---|

| Radiator weight only, g | 448 |

| Heat sink platform dimensions, mm | 38×38 |

| Fan power cable length, cm | 25.5 |

| Fan lighting cable length, cm | 3.5 |

| Backlight adapter length, cm | 60 |

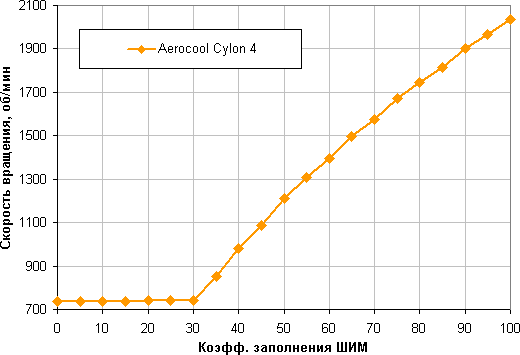

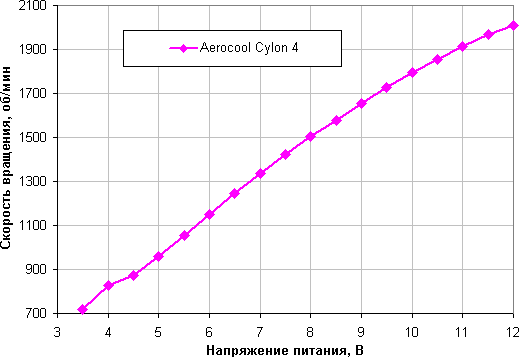

Determining the dependence of the cooler fan speed on the PWM duty cycle and/or supply voltage

A good result has been achieved — there is a gradual increase in the fan rotation speed when the fill factor (FC) changes in the range from 30% to 100%, and there is also a wide adjustment range. It is important to note that at 0% short circuit the fan does not stop rotating, so in a hybrid cooling system with passive mode at minimum load, these fans will need to be turned off and the supply voltage reduced.

The range of adjustment using voltage in this case is approximately the same. The fan stops rotating when the voltage drops to 3.2 V and starts again when it rises to 3.3 V. It is safe to connect such a fan to a 5 V source.

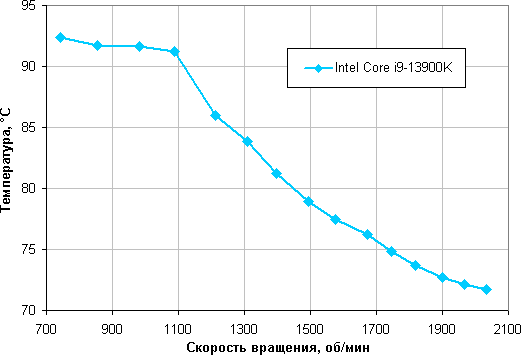

Determining the dependence of the temperature of the Intel Core i9-13900K processor when it is fully loaded on the rotation speed of the cooler fan(s)

In this test, all cores of the Intel Core i9-13900K processor ran at 3.7 GHz.

In practice, at an ambient temperature of 24 degrees, this processor begins to overheat at a short circuit of 45% (which corresponds to approximately 1100 rpm) and below. This occurs because some cores reach a critical temperature, reaching 100 °C. Within this test, the maximum power consumption through the additional 12 V connectors on the motherboard reaches 202 W.

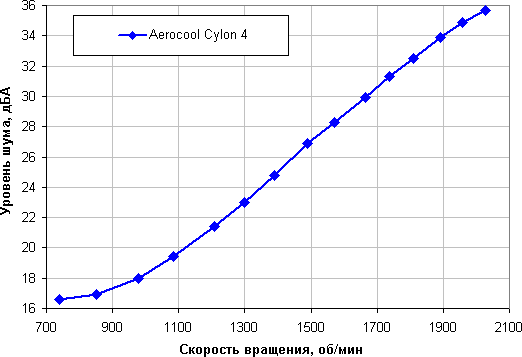

Determining the noise level depending on the rotation speed of the cooler fan(s)

This, of course, depends on individual preference and other factors, but in the case of coolers, noise levels of approximately 40 dBA and above are considered very high for a desktop system. A range of 35 to 40 dBA is rated as tolerable, and noise levels below 35 dBA are considered normal and not too noticeable compared to normal PC components such as case fans, power supply, graphics card and hard drives. If the noise level drops below 25 dBA, then we can assume that the cooler is conditionally silent. The background noise level in the test was 15.9 dBA (the approximate value indicated by the sound level meter). Thus, this cooler can be considered a device with a low noise level.

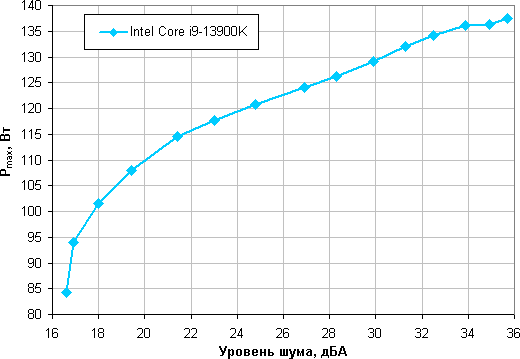

Plotting the dependence of real maximum power on noise level

Let's move on from the testbed parameters to more realistic scenarios. Let's assume that the temperature of the air entering the cooling system from the fan can increase to 44 °C, but we do not want to allow the processor temperature to rise above 80 °C at maximum load. Given these conditions, let's plot the actual maximum power consumption of the processor (denoted as Pmax, previously we used the designation Max. TDP) versus the noise level.

If we take 25 dBA as a conditional noise level, then the approximate maximum power of processors such as the Intel Core i9-13900K at this level will be about 121 W. Hypothetically, ignoring noise levels, the power limits could be increased to approximately 137 watts. It is important to note that this is under conditions of active fan cooling of air heated to 44°C, and at a maximum processor temperature of 80°C (although up to 100°C is acceptable). As the ambient temperature changes or the maximum processor temperature increases, the specified power limits for silent operation and maximum power will also change.

conclusions

To properly understand the findings, it is important to remember that:

The main purpose of testing is to determine the cooling capabilities of the cooler (or LCS). The processors used in the tests act only as a heat source for subsequent evaluation of cooling efficiency in various modes. Thus, the power (heat dissipation) of the processor is deliberately adjusted depending on the capabilities of the cooling system, and can either exceed or be lower than the standard parameters of the processor. The main requirement is that the processor should not overheat within the entire cooling range, while maintaining significant differences in processor temperature.

Based on the AeroCool Cylon 4 air cooler, you can build a computer with a conditionally silent mode (noise level 25 dBA or lower), equipped with an Intel Core i9-13900K processor, provided that the heat dissipation of this or a similar processor under maximum load does not exceed 121 W. It is also important that the air temperature inside the case does not rise above 44 °C, subject to the 80 °C limit on the maximum processor temperature. As air temperatures drop, processor temperature limits increase (up to 100 °C), or noise requirements become more flexible, power limits can be adjusted. The advantages of the cooler include its aesthetic design and compatibility with high-quality memory modules. Also, modding enthusiasts may like the multi-color and multi-zone static or dynamic backlighting, which supports a standard three-pin connection.