We have already looked at tools of this type more than once. We are not talking about grinders in general, but about a specific form factor — a mini grinder. The important thing to note here is the intermediate size, which is not micro with 50mm diameter discs, but not standard with discs starting at 125mm.

Our previous reviews of mini grinders did not provide a clear answer to the question: “Why do I need such a tool?” Perhaps today's review will pave the way to a more informative answer.

Characteristics

| Manufacturer | Nocord |

|---|---|

| Model (item) | Nocord NBG-12.1.20.76 |

| Device type | mini manual cordless angle grinder |

| engine's type | brushless |

| Disc diameter | 3″ (76 mm) |

| Spindle thread | without thread, bore diameter 10 mm |

| Maximum cutting depth (disc overhang) | 13 mm |

| Rotational speed |

|

| Built-in backlight | No |

| Engine blocking when disk jams | yes, with automatic resumption |

| Smooth start | Yes |

| Brake | Yes |

| Accidental restart protection | Yes |

| Dimensions, weight | 230×105 mm, 765 g with casing and battery |

| Battery type | Lithium-ion, charging time 1 hour |

| Voltage | 12 V |

| Capacity | 2 Ah |

| Battery life under load | n/a |

Equipment

The tool provided for testing is supplied in a plastic case with latches. This is a rare feature: only expensive models are usually equipped with cases.

The angle grinder comes complete with a protective cover, a key, one battery along with a charger and three discs: a grinding disc for metal, a cutting disc for metal, and a disc for cutting glass and ceramics. In addition, the set includes printed materials.

Design, control

This mini-tool completely, in every detail, reproduces the appearance of a regular angle grinder. However, there is an exception: the absence of an additional handle. Perhaps for some reason it was decided that it was not required. But, of course, the main reason is that the additional handle simply does not fit (or may get in the way).

And yet, in the process of work, you, by inertia, extend your second hand towards the tool, as if mechanically trying to grab an additional handle. But she's not there!

In fact, a second hand is always needed, regardless of the size and weight of the tool. The problem is not so much the weight of the device, which is easier to hold with two hands, but the precision of the work, which cannot be achieved using only one hand. Making a straight line with a rotating disk while holding the tool with one hand is much more difficult than using the other hand.

Our grinder has a brushless motor, which in theory increases power and reduces energy consumption. The engine is turned on using a slide switch with a lock, standard for all angle grinders. This switch is placed so that it is always easily accessible to the thumb of the right hand.

Our grinder has a brushless motor, which in theory increases power and reduces energy consumption. The engine is turned on using a slide switch with a lock, standard for all angle grinders. This switch is placed so that it is always easily accessible to the thumb of the right hand.

In order to unscrew the bolt, you need to lock the spindle. To do this, there is a recessed spring-loaded button.

The shape of the protective casing ensures complete coverage of the nozzle not only from the side, but also partially from above. The high side of the casing seems excessive, especially considering the specific attachments included in the kit.

A nice addition is the presence of LED indicators on the body of the angle grinder that display the current battery charge level. This is a useful addition, given the lack of built-in indication on the battery itself. It's important to note that these indicators are truly functional, unlike many of the cheap tools we've tested.

The included battery fits into the battery compartment slides and is secured with a latch. There is no chatter in this case, the battery sits firmly.

Instructions

Included with the angle grinder is an instruction manual in Russian, which provides a list of safety precautions during operation, methods for performing various tasks, diagrams and detailed descriptions of work processes. In addition, recommendations are provided on actions in case of possible malfunctions.

Exploitation

Attaching attachments

The grinder comes complete with three discs: a grinding disc for metal, a cutting disc for metal and plastic, and another cutting disc for ceramics.

All three attachments fit easily onto the angle grinder spindle, and the gap between the guard body and the edge of the attachment is 5mm. The fixing bolt must be fully tightened to prevent it from unscrewing spontaneously. Our grinder is equipped with an electric motor brake that stops the spindle in a second. Therefore, if the bolt is not tightened enough, the attachment disc may loosen the bolt during a sudden stop. In this case, the next time you turn it on, there is a risk that the nozzle will come off in a certain direction.

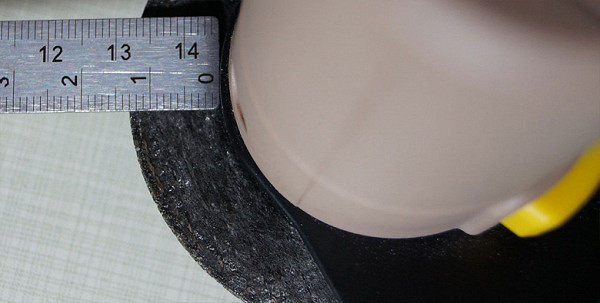

It was noticed that the new disc has a significant cutting depth (disc overhang) of 13 mm. In several previously studied mini-grinders, this figure was limited to only 10 mm. However, it is worth noting that due to the rapid wear of cutting discs, the joy of increased cutting depth may be short-lived.

We will not use all the accessories included in the supply, as our goal is not to create a work of art. Our task is simple: test the power of the angle grinder. Will a mini-grinder be able to handle cutting or processing material without jamming? After all, in addition to its more compact size, the mini-grinder also has lower engine power, which is an obvious difference from standard models.

Sawing

So, we will carry out practical work in cutting mode. In the next video you can watch the process of sawing thin (0.5 mm) and thick (2 mm) metal, as well as a sandwich panel.

It's time to be amazed by the unexpectedly high power of the mini-grinder. The tool coped with the proposed materials almost without difficulty. The only time when cutting thick metal the protection turned on for a second, stopping the engine due to strong resistance. However, as soon as the resistance went away, the motor resumed operation. The grinder cut the rest of the materials easily. There is a slight melting of the plastic edges when processing the sandwich panel, but perhaps this is still better than microcracks that occur when cutting with a regular knife.

The rotation speed of the tool corresponds to the values declared by the manufacturer: close to 17,900 rpm compared to the nameplate 18,500 rpm.

It is clear that the manufacturer managed to achieve an optimal combination of spindle speed and engine power. The grinder can even cope with 2 mm metal, which is hardly included in the range of tasks of a mini-tool.

But these were all synthetic tests for cutting materials. Yes, we found out that the grinder’s power is enough for any job, but where is it, reality? It turns out that again it was not possible to find a worthy and appropriate use for a mini-grinder? But that’s not true! As always, the law of the roast rooster worked: it pecks accurately, but unexpectedly. In short: the author needed shear bolts. The same ones that attach the augers to the snow blower shaft.

Due to the snowy winter, the popularity of these bolts has increased significantly. In short, there was a need to replace them, but I was not happy with the cost of such bolts. It’s easier and much cheaper to make such a bolt yourself: just machine shallow grooves at both ends in a regular store bolt. For such a relatively delicate operation, a standard size grinder is not suitable: it is too inaccurate due to its high power and large size. In this case, the mini-grinder came in handy.

Three minutes of work — and the shear bolt is ready. It differs from the “real” one only in the low accuracy of the grooves, which in practice does not play any role.

It seems that similar scenarios can be found in real life a lot. They may not be as frequent as standard situations, for example, “cutting off a 5-centimeter corner,” but they still occur. Such a tool, even if it sits idle for a long time, may well come in handy. As usual, unexpected.

Care

To make the tool look and feel good, after work it is enough to wipe it, removing dust, especially concrete dust. The battery should be stored separately, in a warm room, and recharged regularly.

Battery

The angle grinder is supplied with one battery and a charger.

conclusions

Despite its compact size, the Nocord NBG-12.1.20.76 angle grinder has excellent power. The issue of battery life remains unresolved, as testing battery life with reliable and repeatable results is challenging. Battery consumption greatly depends on the work performed and the effort expended by the motor. The battery will probably be enough for 15-20 minutes of operation under medium loads.

Pros:

- compactness

- high speed and power

- keyless mechanism for fixing the position of the casing

- electric engine brake

- presence of battery charge indicators

Minuses:

- no speed control